Are you tired of the recurring costs and logistical hassles associated with purchasing bulk nitrogen? Investing in an on-site nitrogen generator could be the game-changer your business needs. But before diving in, it’s crucial to understand the factors that influence nitrogen generator prices. This knowledge will not only help you make an informed decision about choosing a cost-effective nitrogen generator but could also save your business thousands of dollars each year.

The price of a nitrogen generator can vary significantly based on factors like capacity, purity level, and technology used. On average, small to medium-sized nitrogen generators can cost between $3,000 to $50,000, while large, industrial-grade generators may exceed $100,000. Understanding these factors will help you make an informed decision that best suits your business needs.

What is a Nitrogen Generator?

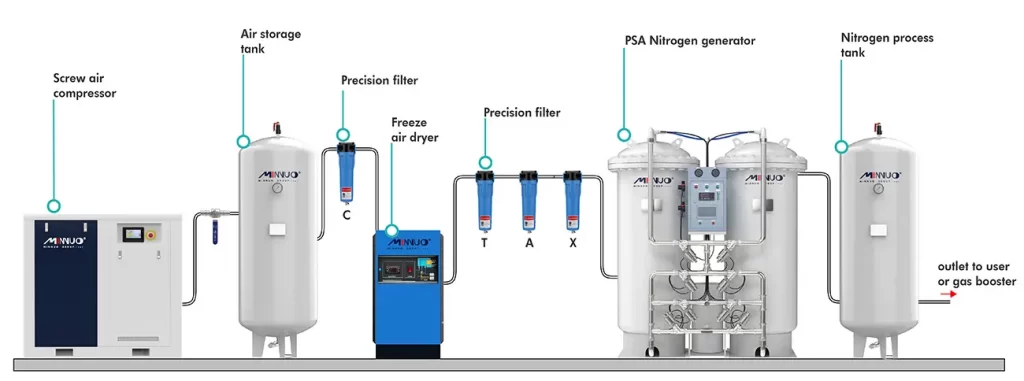

A nitrogen generator is a device that separates nitrogen from the air we breathe, which is composed of approximately 78% nitrogen and 21% oxygen. Using advanced technologies like Pressure Swing Adsorption (PSA) or membrane separation, a nitrogen generator efficiently extracts and purifies nitrogen for use in various industrial applications. This on-site generation of nitrogen eliminates the need for delivered nitrogen supplies, offering a cost-effective and reliable solution for businesses that require a steady, high-purity nitrogen source.

Types of Nitrogen Generators

When it comes to nitrogen generators, the type of generator you choose is one of the most significant determinants of price. Let’s take a closer look at the three main types:

PSA (Pressure Swing Adsorption) Nitrogen Generators

These are commonly used in manufacturing industries due to their efficiency in producing high-purity nitrogen. Prices for PSA generators typically range from $10,000 to $30,000, depending on capacity.

Membrane Nitrogen Generators

These are often preferred in industries where lower nitrogen purity (95-99.5%) is acceptable, such as food packaging and fire prevention. Membrane generators are generally less expensive, with prices ranging from $3,000 to $20,000.

Cryogenic Nitrogen Generators

These are used for large-scale industrial applications where very high-purity nitrogen is required. Due to their advanced technology and large capacity, cryogenic generators can cost upwards of $100,000.

Key Factors Influencing Costs

Several factors contribute to the overall cost of a nitrogen generator. Understanding these will help you choose the right one for your business:

Capacity and Output Rate

The larger the capacity and output rate of the generator, the higher the cost. For example, a generator producing 10 m3 of nitrogen per hour will be more expensive than one producing only 1 m3 /h.

Purity Level of Nitrogen

Different industries require different nitrogen purity levels. A generator providing 99.99% purity will cost more than one providing 95% purity because it requires more advanced filtration technology. For instance, increasing purity from 95% to 99.999% can increase the cost by 20-30%.

Technology and Innovation

Generators equipped with the latest technology, such as energy-efficient systems or automated controls, tend to be more expensive. However, these features can lead to long-term savings by reducing operating costs.

Brand and Manufacturer

Established brands known for reliability and quality may charge a premium. For example, a nitrogen generator from a top-tier manufacturer like Atlas Copco or Parker Hannifin might cost more, but it often comes with better warranties and customer support.

Customization and Additional Features

If your business requires a custom-built nitrogen generator or additional features like remote monitoring, expect to pay more. Customization can add 10-15% to the base cost of the generator.

Accessories and Ancillary Components

The price of a nitrogen generator can also be significantly affected by the need for additional equipment and accessories. These include:

- Buffer Tanks: Buffer tanks are essential for stabilizing the nitrogen flow and ensuring consistent pressure. While necessary for many setups, they can add several thousand dollars to the overall cost depending on their size and material.

- Compressors: A nitrogen generator requires a high-quality air compressor to supply the raw air needed for nitrogen production. The cost of a compressor can vary widely based on its capacity, type (oil-free or lubricated), and brand, typically ranging from $5,000 to $20,000.

- Dryers: Air dryers are used to remove moisture from the compressed air before it enters the nitrogen generator. Depending on the required dryness level and type (refrigerated or desiccant), a dryer can add an additional $1,000 to $10,000 to the system’s price.

- Storage Tanks: Nitrogen storage tanks are necessary for holding the generated nitrogen before it is used in applications. The cost of storage tanks varies based on their size and material, with prices ranging from $1,000 to $10,000 or more.

Maintenance and Operating Costs

While the initial purchase price is important, don’t forget to factor in long-term maintenance and operating costs. For example, energy consumption alone can significantly impact the total cost of ownership.

Detailed Cost Breakdown

To give you a better idea of what to expect, here’s a breakdown of nitrogen generator costs based on different categories:

- Small Flow Nitrogen Generators

Typically cost between $3,000 and $10,000. These are suitable for small businesses or applications with low nitrogen requirements.

- Mid Flow Nitrogen Generators

Prices range from $10,000 to $50,000. These generators are ideal for medium-sized operations with moderate nitrogen demands.

- Large Flow Nitrogen Generators

These can cost anywhere from $50,000 to over $100,000. Large flow models are designed for large industrial applications where high-purity nitrogen is crucial.

When you have no way to determine your flow rate, you can contact our engineers who will give you professional advice and assist you in purchasing the right nitrogen generator.

Cost-Benefit Analysis: Is It Worth the Investment?

On-Site Generation vs. Bulk Supply

One of the biggest decisions you’ll face is whether to generate nitrogen on-site or continue purchasing it in bulk. Here’s a simple cost comparison:

- Bulk Supply: If your company spends $10,000 annually on bulk nitrogen, this cost will continue to accumulate year after year. Over a decade, you could easily spend $100,000 or more.

- On-Site Generation: Investing in a $30,000 nitrogen generator could pay off in just three years, assuming similar usage levels. After that, the only costs you’ll incur are maintenance and electricity.

Costs of On-site Nitrogen Generation Systems

Unlike bottled nitrogen, calculating the costs of using on-site nitrogen is more complex. The costs of on-site nitrogen generation mainly consist of the following: electricity consumption, labor costs, equipment maintenance costs, and equipment depreciation costs.

- Electricity consumption mainly comes from the air compressor, refrigerated dryer, nitrogen purification unit, etc. Generally, the higher the power of the air compressor, the higher the energy consumption of the entire nitrogen generation system.

- Labor costs: Nitrogen generators typically do not require constant monitoring and only need regular inspections. These costs are often negligible.

- Equipment maintenance costs: The maintenance and upkeep costs of nitrogen generators primarily involve regular replacement of filters in the air compressor, changing lubricating oil, and replacing the oxygen analyzer probe in the nitrogen generator. Air filters are replaced approximately every 4000 hours, oil and gas filters every 8000 hours, oil filters every 2000 hours, and lubricating oil every 2000 hours. Compressed air filters are replaced every 4000 hours, and on average, the oxygen analyzer probe is replaced every two years.

- Equipment depreciation costs: Usually calculated over a depreciation period of 10 years.

Conclusion

Nitrogen generator prices vary widely based on capacity, purity level, technology, and other factors. By understanding these factors and conducting a thorough cost-benefit analysis, you can make an informed decision that best suits your business needs.

How to Buy a Nitrogen Generator?

At Minnuogas, we offer a range of brand-new nitrogen generators including membrane nitrogen generators, PSA nitrogen generators, and cryogenic air separation systems for sale. Feel free to place an order for the nitrogen generator you need, and we ensure competitive pricing. If you are unsure about the model or type of nitrogen generator required, please contact our engineers anytime. We will provide you with customized solutions and a price quote.

FAQs

The nitrogen output of a generator depends on the specific model and configuration. Typically, small-scale nitrogen generators can produce a few cubic meters of nitrogen per hour, while larger industrial models can produce hundreds of cubic meters per hour. To recommend the most suitable equipment, it would be helpful to understand your specific application needs.

A nitrogen generator typically has a lifespan of 10 to 15 years, depending on maintenance and operating conditions. With regular maintenance, the lifespan can be extended. We offer comprehensive after-sales service and maintenance plans to ensure your equipment operates at peak performance.

Nitrogen generators are highly reliable, especially when properly maintained. Modern nitrogen generators are designed with advanced technology to provide continuous operation with minimal downtime. The generators we offer undergo rigorous testing to ensure they meet the highest standards of stability and durability, making them suitable for a wide range of industrial applications.

sales2:+86 17506119168

sales2:+86 17506119168