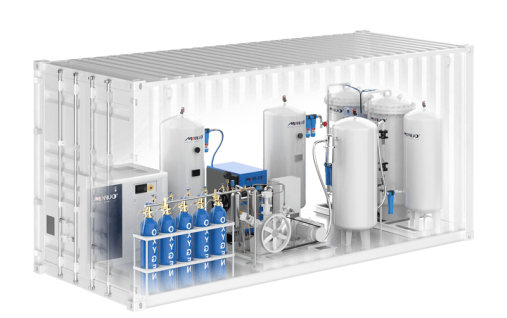

Intelligent and low consumption

Low electricity consumption for oxygen production

Our VPSA system uses lithium-based molecular sieves, which are used in large quantities, and the power consumption of pure oxygen is between 0.3 and 0.32 degrees, while the power consumption of our new 380 VPSA project is 0.28 degrees, the best in the industry.

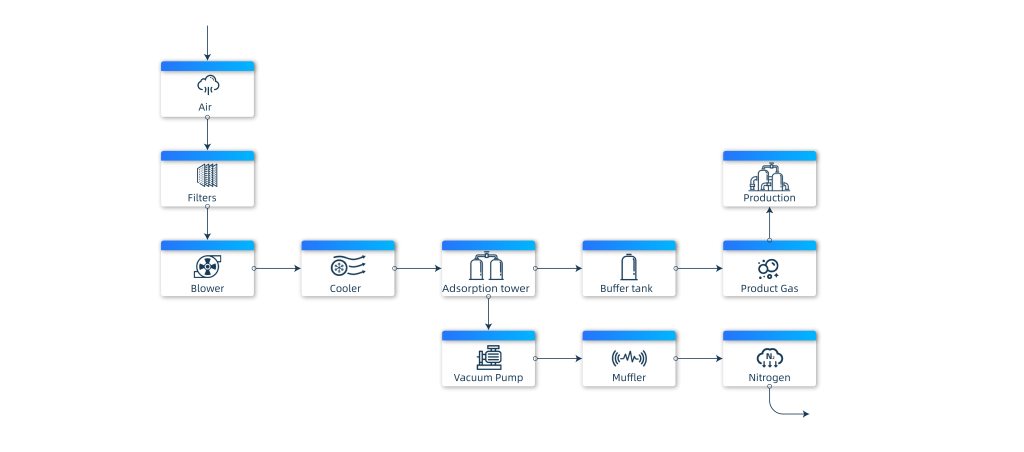

Simple operation and high degree of automation

1 motor and 11 valves can achieve fully automatic oxygen production, which can be unattended.

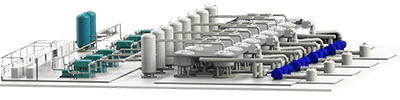

Low ancillary costs such as water, floor space and staffing

One third of the water, one half of the floor space and one quarter of the manpower of traditional deep-cooling for the same scale.

sales1:+1 213 276 6245

sales1:+1 213 276 6245