Hydrogen recovery refers to the industrial production process in which hydrogen discharged undergoes treatments for dust, oil, oxygen, water, etc., so that the quality of the hydrogen gas can meet the production requirements again. It is a collective term for the secondary recycling system.

The hydrogen recovery unit is designed to remove solid impurities from the hydrogen gas. Then the gas enters the drying tower and goes through molecular sieve adsorption to reach the required dew point. Finally, the purified hydrogen is developed and utilized for secondary use.

Parameter |

Value |

|---|---|

|

Unit scale |

10~300000Nm3/h |

|

Purity |

99%~99.9995%(V/V) |

|

Pressure |

0.4~5.0Mpa(G) |

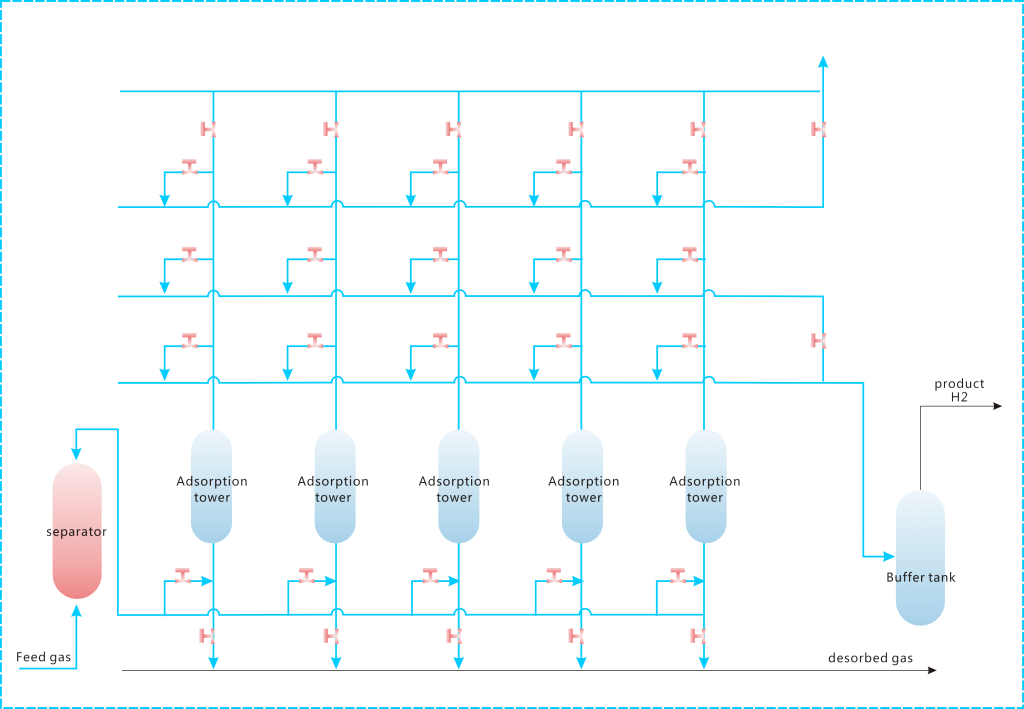

Multi-tower PSA technology is adopted for hydrogen purification. The working steps are divided into adsorption, pressure reduction, desorption, pressure rise, etc. The adsorption towers are staggered in the working steps to form a closed loop to ensure continuous input of raw materials and continuous output of products.

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales1:+1 213 276 6245

sales1:+1 213 276 6245