Oxygen generation technology is crucial in the industrial and medical fields, especially the two large pipeline equipment, VPSA (pressure swing adsorption) and PSA (pressure swing adsorption) oxygen generators. When enterprises or individuals choose oxygen generators, how can they choose the most suitable equipment according to their own situation? We will compare the working principles, performance, application scenarios and optimization solutions of VPSA oxygen generators and PSA oxygen generators to help you regain confidence when purchasing equipment. Through a comprehensive analysis of these two oxygen generation technologies, you will better understand their advantages and scope of application, and find the oxygen generation solution that best suits you.

VPSA (vacuum pressure swing adsorption) and PSA (pressure swing adsorption) are two common oxygen generation technologies. PSA oxygen generators separate oxygen by pressurization, which is suitable for small and medium-sized occasions, with fast start-up, structural arrangement, sparse and high oxygen purity, and generally 90%-95%; while VPSA oxygen generators use vacuum desorption operation, which is more energy-efficient and suitable for large-scale industrial applications. The oxygen purity can reach 95%-99%, but the initial investment is increased. The choice of which technology should be determined based on the company’s oxygen demand, application scenarios, restrictions and budget.

What are VPSA and PSA oxygen concentrators?

PSA oxygen concentrator

PSA oxygen concentrator, or pressure swing adsorption oxygen concentrator, separates oxygen from air through pressure. Its core principle is to use molecular sieves to adsorb oxygen from the air, so that oxygen can be realized. The process relies on pressure and pressure to separate. During operation, the molecular sieve alternates between adsorption under pressure and releases oxygen under air pressure, thereby continuously separating oxygen.

VPSA oxygen concentrator

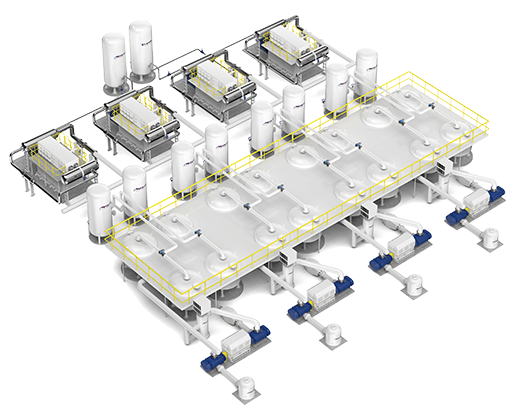

VPSA oxygen concentrator, vacuum pressure swing adsorption oxygen concentrator, uses the same separation method as PSA, but uses vacuum operation during the desorption process, so that the system operates at a lower pressure and nitrogen is extracted from the molecular sieve by a vacuum pump. This design greatly reduces the demand for compressed air and improves energy efficiency, and is particularly suitable for large-scale and long-term oxygen production occasions.

Comparison of the working principles of VPSA oxygen concentrator and PSA oxygen concentrator

Working principle of PSA oxygen concentrator

PSA oxygen concentrator separates oxygen from air through compressed air. Nitrogen in the air is adsorbed by the molecular sieve, while oxygen passes through the molecular sieve and is collected. The molecular sieve releases the adsorbed nitrogen during adsorption, and the system can operate in a cycle. PSA technology is relatively simple and suitable for small and medium-sized oxygen demand occasions.

Working principle of VPSA oxygen generator

The adsorption process of VPSA oxygen generator is carried out under low pressure conditions close to atmospheric pressure. After the molecular sieve is adsorbed, oxygen is extracted by vacuum pump. This vacuum desorption process not only improves the overall efficiency of the system, but also makes the VPSA oxygen generator particularly suitable for large-scale industrial occasions, capable of long-term efficient operation and high nitrogen supply.

Application scenarios of VPSA and PSA oxygen generators

Typical applications of PSA oxygen generators

- Medical field: PSA oxygen generators are widely evaluated in hospitals and clinics to provide oxygen for surgery, emergency treatment and respiratory support.

- Food packaging: In food production, PSA oxygen generators can provide support for protective gas supply and extend the shelf life of food.

- Sewage treatment: PSA equipment provides oxygen support for sewage treatment plants, promotes bactericidal activity, and thus improves sewage purification efficiency.

Typical applications of VPSA oxygen generators

- Steel smelting: VPSA oxygen generators play an important role in steel production, improving combustion efficiency by providing high-purity oxygen.

- Glass manufacturing: High-temperature furnaces require a large amount of oxygen to maintain high-temperature production. VPSA oxygen generators can provide continuous oxygen supply for glass manufacturing.

- Chemical production: VPSA oxygen generators can provide high-purity oxygen for chemical reactions to ensure the safety and efficiency of efficient reactions.

Performance comparison between VPSA and PSA oxygen generators

Oxygen purity and output

PSA oxygen generators usually provide 90%-95% oxygen purity, which is suitable for most small and medium-sized industrial needs. VPSA oxygen generators can provide 95%-99% high-purity oxygen, which is very suitable for industrial occasions with high requirements for oxygen quality.

Evaporator

VPSA oxygen generators are more effective than PSA oxygen generators due to the use of vacuum debonding technology. For long-term and large-scale operation, the evaporator of VPSA equipment performs better. PSA oxygen generators require higher pressure and have a relatively high friction coefficient.

Equipment occupancy and structure

PSA oxygen generators have compact equipment design and compact structure, which are suitable for space-based occasions. However, due to the high complexity of the equipment and the increase in customization, the VPSA oxygen concentrator usually requires an expanded installation space and is more suitable for industrial occasions.

Startup speed

The PSA oxygen concentrator starts quickly and can supply oxygen within a quarter of an hour, making it particularly suitable for emergency medical situations and rapid response applications. In contrast, the startup time of the VPSA oxygen concentrator is suitable for scenarios where emergency medical treatment requires long-term stable operation.

Advantages of VPSA oxygen concentrator and PSA oxygen concentrator

Advantages of PSA oxygen concentrator

- Compact structure: Due to the compact design and small customized equipment, the PSA oxygen concentrator is very suitable for small places with limited space, such as clinics and laboratories.

- Fast startup speed: PSA equipment starts within tens of seconds, quickly providing oxygen for emergency needs.

- Simple maintenance: The structure is relatively simple and easy to maintain, which is suitable for daily use by small and medium-sized enterprises.

Disadvantages of PSA oxygen concentrator

- Higher tension: PSA equipment relies on high pressure to achieve oxygen separation, and the tension increases with long-term operation, resulting in higher operating costs.

- Reduced oxygen purity: Although 90%-95% oxygen purity is sufficient to meet most needs, PSA may have gaps for industries with high-purity oxygen requirements.

Advantages of VPSA oxygen concentrators

- High efficiency: Through vacuum desorption operation, VPSA systems are able to provide efficient oxygen separation with nitrogen tiles.

- High oxygen purity: VPSA equipment generally provides 95%-99% high oxygen, which is particularly suitable for industries with strict requirements on oxygen purity.

- Suitable for large-scale needs: VPSA oxygen concentrators can operate continuously for a long time and are suitable for industrial occasions that require a large amount of oxygen.

Disadvantages of VPSA oxygen concentrators

- High initial investment: The purchase and installation costs of VPSA equipment are high, which is suitable for large enterprises and long-term investment.

- Large structure: The design complexity of VPSA system increases and the installation requirements are higher.

How to choose the oxygen concentrator that best suits you?

Choosing a VPSA or PSA oxygen concentrator depends on your specific needs. The following points are for reference:

- If your oxygen demand is small and your budget is limited, PSA oxygen concentrators are an ideal choice. It has a compact equipment layout and simple maintenance, and can provide efficient oxygen supply for small and medium-sized medical institutions, food factories and other occasions.

- If your company has a large demand for oxygen and has strict requirements on oxygen purity, VPSA oxygen generator is a better choice. It provides high-purity and low-purity oxygen supply for large industrial occasions such as steel smelting, glass manufacturing, and chemical production.

Future trend of VPSA and PSA oxygen generators

In the future, as technology advances, VPSA and PSA oxygen generators will focus on energy saving, efficiency, and environmental protection. New molecular sieve materials will improve oxygen purity and reduce energy consumption. Standardized control systems will enhance equipment performance, streamline operations, and enable remote monitoring and automated management.

Frequently Asked Questions (FAQ)

What are the main differences between VPSA and PSA oxygen generators?

VPSA oxygen generators separate oxygen through vacuum operation, which is more energy-efficient and suitable for large-scale industrial applications; while PSA oxygen generators separate oxygen through pressurization and are suitable for small and medium-sized applications.

Which oxygen concentrator is suitable for high-purity oxygen demand?

VPSA oxygen concentrators can provide 95%-99% high-purity oxygen, which is suitable for industries with high requirements for oxygen quality.

Does the PSA oxygen concentrator start up quickly?

Yes, the PSA oxygen concentrator starts up quickly and can produce oxygen within a quarter, which is suitable for emergency situations.

Does the VPSA oxygen concentrator have a low evaporation coefficient?

Yes, the VPSA oxygen concentrator uses vacuum debonding technology, which is energy-efficient and suitable for industrial occasions with long-term operation.

Conclusion

VPSA oxygen concentrator and PSA oxygen concentrator each have their own unique advantages and are suitable for different industry needs. If you are looking for high-precision, large-scale oxygen supply, VPSA oxygen concentrator is an ideal choice; if your needs are smaller and you want to control costs, PSA oxygen concentrator is more suitable. If you still have doubts about choosing equipment, don’t worry, MINNUO always insists on providing personalized services to customers to ensure that you buy the most suitable machine within your budget.

sales2:+86 17506119168

sales2:+86 17506119168