In today’s increasingly accelerated industrialization, industrial oxygen generators have become an important part of modern industrial and medical systems. It not only provides key energy support for industries such as steel and fertilizers, but also plays an irreplaceable role in medical and environmental protection. With the continuous advancement of technology, the history of industrial oxygen generators has also undergone several technological revolutions. From the initial liquefied air method to today’s intelligent and environmentally friendly oxygen production technology, every step of development is driving the transformation of the industry. This article will give you an in-depth understanding of the evolution of industrial oxygen concentrators. You will see how this field continues to innovate and promote the booming development of industries such as steel, fertilizers, and medical care.

This article reviews the technological evolution of industrial oxygen generators in detail, focusing on the development of liquefied air separation, pressure swing adsorption (PSA) technology, membrane separation technology, intelligent oxygen production technology, and green environmental protection oxygen production technology. With the continuous advancement of technology, oxygen generators have not only improved industrial production efficiency, but also provided strong support for fields such as medical and environmental protection. In the future, with the trend of intelligent and green development, industrial oxygen generators will play a more important role in promoting global sustainable development.

The origin of industrial oxygen generators: a leap from laboratory to industrialization

The discovery of oxygen and the birth of industrial oxygen production

The discovery of oxygen marks a major breakthrough in the field of chemistry. In 1774, British chemist Joseph Priestley decomposed oxygen by heating potassium chlorate. This discovery not only changed human understanding of air, but also laid the foundation for the subsequent oxygen production technology. However, at the end of the 18th century, oxygen was still in the laboratory research stage and had not yet been mass-produced.

With the advent of the Industrial Revolution, demand continued to increase, especially in the fields of steel smelting and fertilizer production, and there was an urgent need to find an economical and efficient method of oxygen production. It was this demand that prompted the development of oxygen production technology.

Liquefied air technology: a new era of oxygen production

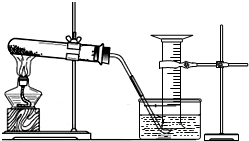

In 1895, German engineer Carl von Linde invented liquefied air separation technology. This technology separates oxygen and nitrogen by cooling air to extremely low temperatures to liquefy it. The liquefied air method became one of the earliest industrial oxygen production methods, which provided a technical basis for the large-scale production of oxygen.

Although the liquefied air technology achieved great success at the time, the liquefaction process required extremely low temperature and a large amount of energy, the cost of oxygen production was high, and the equipment was large and complex, which limited its wide application. Therefore, although the liquefied air method played an important role in industries such as steel and fertilizers, it was not the most ideal solution.

The rise of compressed air separation in the early 20th century

Compressed air separation: a new choice for industrial oxygen production

With the advancement of industrialization, compressed air separation has gradually become the mainstream technology for oxygen production. This technology compresses air under high pressure and then uses expansion and temperature differences to separate oxygen and nitrogen. The compressed air separation method greatly outperforms the liquefied air method in energy efficiency and cost, making it widely used in fields like steel and fertilizer production.

The development of this technology has made the production of oxygen no longer limited by the huge demand for cryogenic equipment, reducing energy consumption and the complexity of equipment maintenance, thereby promoting the popularization and application of oxygen in various industrial fields.

Application of oxygen in the steel and fertilizer industries

After entering the 20th century, oxygen began to play an increasingly important role in steel smelting and fertilizer production. In steel production, oxygen is used in blast furnace ironmaking, which enhances combustion efficiency and reduces energy consumption. In fertilizer production, oxygen is used in ammonia synthesis reactions, greatly improving the production efficiency of nitrogen fertilizers.

The widespread use of oxygen not only improves production efficiency, but also reduces production costs, becoming an indispensable core resource in the process of industrialization.

Mid-20th century: Innovation of PSA technology and membrane separation method

Pressure swing adsorption (PSA) technology: improving oxygen production efficiency

In the mid-20th century, the emergence of pressure swing adsorption (PSA) technology marked a new stage in oxygen production technology. PSA technology can efficiently separate oxygen and nitrogen through the selective adsorption of molecular sieves at different pressures. Compared with traditional compressed air separation methods, PSA technology has obvious advantages in improving oxygen purity and reducing energy consumption.

The emergence of PSA technology has not only promoted the application of oxygen in industrial production, but also promoted its widespread use in medical, electronic, semiconductor and other fields. Especially in small oxygen production equipment, PSA technology has become a new standard for oxygen production with its high efficiency and low cost.

Membrane separation technology: a win-win situation for energy saving and environmental protection

Membrane separation technology has gradually become another emerging method for oxygen separation since the 1970s. Using special membrane materials, membrane separation technology can efficiently separate oxygen and nitrogen, with the advantages of simple operation, high energy efficiency and low cost. Compared with traditional compressed air separation and PSA technology, membrane separation technology equipment is small and energy-efficient, and is widely used in small and medium-sized enterprises and civilian oxygen production.

The emergence of membrane separation technology not only reduces the cost of oxygen production, but also promotes the popularization and application of oxygen equipment, becoming one of the representatives of environmentally friendly oxygen production technology.

21st century: the integration of intelligence and green environmental protection

Intelligent oxygen production technology: improving management efficiency and energy saving effect

In the 21st century, intelligent oxygen production technology has gradually become the mainstream trend of the industry. Combined with advanced technologies such as artificial intelligence, the Internet of Things, and big data, the intelligent oxygen generator can automatically adjust the oxygen production process, achieve 24-hour unattended operation, and optimize the production process through remote monitoring and data analysis to improve oxygen production efficiency.

Intelligent technology not only makes the equipment run more efficiently, but also improves the level of refined management and reduces the risks and costs of manual operation. Through intelligence, oxygen production equipment can automatically adjust oxygen production according to real-time demand to ensure the stability and efficiency of the production process. In large steel plant blast furnace oxygen supply systems, IoT-enabled intelligent oxygen generators (adopting VPSA technology, oxygen purity ≥99.2%) have realized a 12%–18% reduction in system comprehensive energy consumption by dynamically matching oxygen supply with blast furnace combustion load. Meanwhile, manual operation intervention has been reduced by 75%–85%, effectively lowering the risk of unplanned equipment downtime. This data is based on continuous 72-hour operation tests under 0.7 MPa inlet pressure and ≤500m altitude conditions.

Green environmental protection and energy saving: the core requirements of modern oxygen production

With the increasingly stringent global environmental protection policies, green and energy-saving oxygen production technology has become an important direction for the development of the oxygen production industry. Modern oxygen production equipment adopts more advanced airflow optimization design, more efficient separation devices and waste gas recovery technology, which effectively reduces energy consumption and waste gas emissions.

Green oxygen production technology not only meets the requirements of sustainable development, but also brings significant economic benefits to industrial enterprises through energy conservation and emission reduction. Nowadays, many companies have begun to invest in the research and development of low-carbon oxygen production technology, driving the oxygen production industry to develop in the direction of green environmental protection.

Looking to the future: Sustainable development of oxygen production technology

Future oxygen production technology will pay more attention to circular economy and resource optimization. Innovative green energy such as solar energy and wind energy will be incorporated into the design of oxygen production equipment to promote low-carbon production on a larger scale. Through continuous technological innovation, oxygen production equipment can not only improve energy efficiency and reduce carbon emissions, but also make greater contributions to global energy sustainable development.

Conclusion

The development history of industrial oxygen generators is a history full of innovation and change. From the liquefied air technology in the late 19th century, to the PSA technology in the mid-20th century, to the intelligent and green environmental protection technology in the 21st century, each breakthrough has promoted the rapid development of many fields such as industry and medical care. With the continuous advancement of science and technology, oxygen production technology will continue to improve and become an important driving force for the global industrialization, intelligence and greening process. In the future, with the continuous innovation of technology and the improvement of global environmental protection requirements, industrial oxygen generators will make greater contributions to promoting sustainable development, improving industry efficiency and reducing environmental pollution.

MINNUO has always been at the forefront of science and technology. Our products are of high quality and low energy consumption. Our technicians can provide the best air solutions according to the specific conditions of customers, which are widely praised by customers from all over the world. If you want to know more, please come to consult.

sales2:+86 17506119168

sales2:+86 17506119168