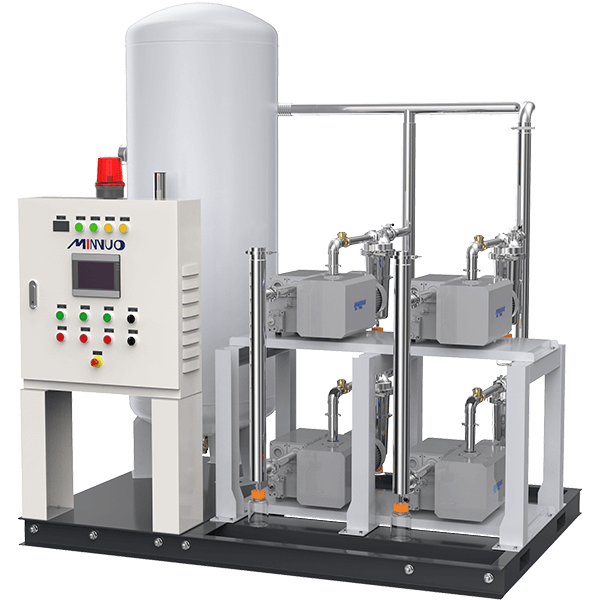

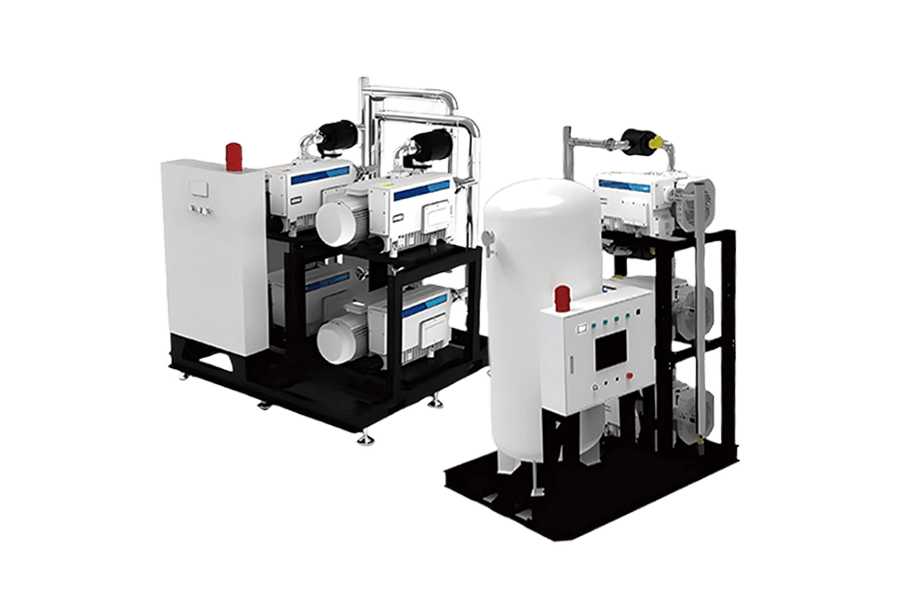

Medical Vacuum Plant

The MINNUO medical vacuum suction system provides efficient, stable, and uninterrupted negative pressure suction support for hospitals and healthcare institutions. We use advanced technology and equipment to ensure that critical areas such as operating rooms and ICUs maintain a clean and safe negative pressure environment.

- Motor Power: 5.5 kW/unit

- Rated Pumping Speed: 200 m³/h (3333 LPM)

- Ultimate Vacuum: 0.1 mbar

- Motor Noise: ≤70 dB (indoor)

- Vacuum Range: -0.048 MPa to -0.087 MPa

Application Areas Of Medical Vacuum Plant

Operating Rooms and Emergency Rooms

Medical Vacuum Supply provides reliable negative pressure suction support to ensure cleanliness and safety during surgical procedures.

ICUs and Intensive Care Units

Medical Vacuum Supply provides continuous negative pressure suction support, helping to clear airways and ensuring smooth breathing for patients.

Anesthesia Waste Gas Disposal System

The MINNUO medical vacuum system offers anesthesia waste gas disposal solutions, effectively removing anesthesia waste gases generated during surgery.

Our Healthcare Vacuum Plant Advantages

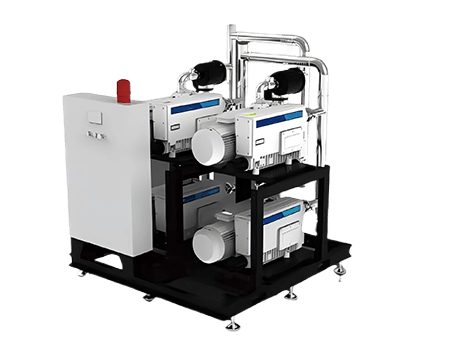

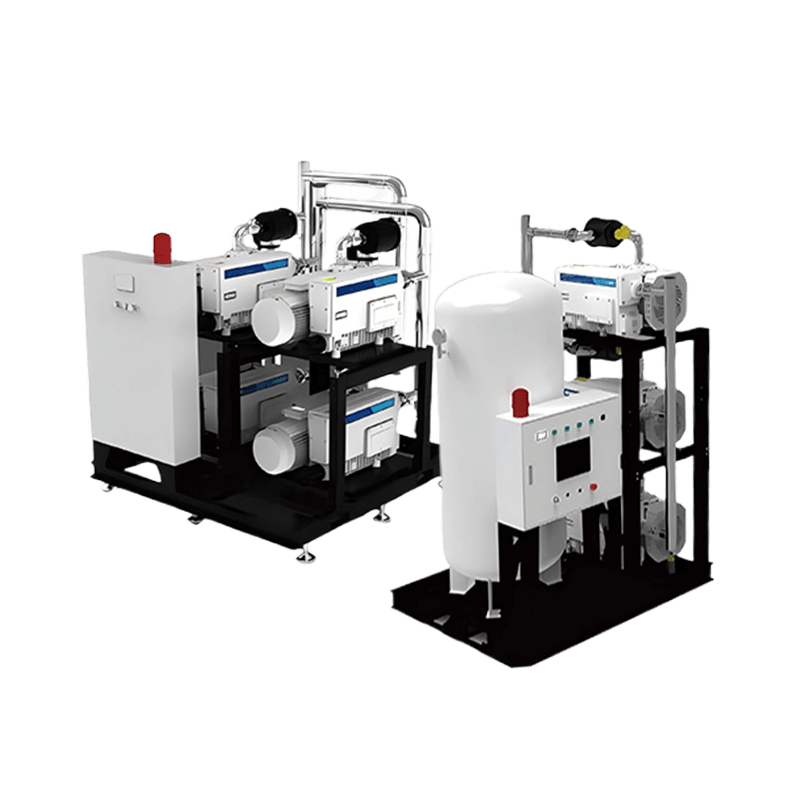

MINNUO medical vacuum suction system uses an oil-sealed rotary vane vacuum pump, combined with efficient filtration devices and a bacterial filtration system, ensuring that the negative pressure environment in medical settings meets strict hygiene and safety standards. The system is designed with redundancy, featuring both a primary and backup unit to ensure continuous operation under any circumstances.

With an integrated skid-mounted design and modular assembly, the system operates stably without being affected by temperature or seasonal changes. It is energy-efficient, environmentally friendly, and requires no water.

It continues to function smoothly even in high-altitude areas. The system is easy to select and comes in a variety of models.

Equipped with intelligent monitoring, an alarm system, and easy post-installation maintenance.

| Specification | Parameter | ||||

|---|---|---|---|---|---|

| Maximum power(kW) | Pumping speed(m3/h) | LxWxH(mm) | Touch screen(inch)) | Noise dB(A) | |

| YMVR-1.1T | 1.1×3 | 80 | 1440x748x1900 | 7 | 65 |

| YMVR-2.2T | 2.2×3 | 126 | 1440x748x1920 | 7 | 68 |

| YMVR-3.0T | 3.0×3 | 200 | 1440x748x1920 | 7 | 69 |

| YMVR-5.5T | 5.5×3 | 400 | 1940x840x2200 | 7 | 74 |

| YMVR-7.5T | 7.5×3 | 600 | 1940x840x2200 | 7 | 76 |

| YMVR-5.5Q | 5.5×4 | 600 | 1940x1640x1880 | 7 | 74 |

| YMVR-7.5Q | 7.5×4 | 900 | 1940x1640x1880 | 7 | 76 |

| YMVC-3.0D | 3*2 | 100 | Customizable | 7 | / |

| YMVC-4.0D | 4*2 | 180 | 7 | ||

| YMVC-5.5D | 5.5*2 | 250 | 7 | ||

| YMVC-7.5D | 7.5*2 | 360 | 7 | ||

| YMVC-3.0T | 3*3 | 200 | 7 | ||

| YMVC-4.0T | 4*3 | 360 | 7 | ||

| YMVC-5.5T | 5.5*3 | 500 | 7 | ||

| YMVC-7.5T | 7.5*3 | 720 | 7 | ||

| YMVC-3.0Q | 3*4 | 300 | 10 | ||

| YMVC-4.0Q | 4*4 | 540 | 10 | ||

| YMVC-5.5Q | 5.5*4 | 750 | 10 | ||

| YMVC-7.5Q | 7.5*4 | 1080 | 10 | ||

Medical Vacuum Plant Based OnOil-less Claw Vacuum Pump

MINNUO medical vacuum system includes various models with maximum power ranging from 1.1 kW to 7.5 kW, pumping speeds from 80 m³/h to 1080 m³/h, and noise levels between 65 and 76 dB(A). The equipment dimensions are customizable, with standard touch screen sizes of 7 to 10 inches, meeting the needs of different medical environments.

Unmatched Reliability and Performance in Medical Vacuum Pumps

Our medical vacuum pumps deliver unmatched reliability and performance, ensuring continuous, efficient operation for your healthcare needs.

The main technical features of our product.

Efficient Negative Pressure Suction

The system delivers a pumping capacity of 200 m³/h through a high-performance rotary vane vacuum pump, meeting the demands of large-scale medical environments.

Four-Layer Sterilization Technology

Equipped with a four-layer sterilization system, including high-precision filtration, UV sterilization, ionization treatment, and photocatalytic technology, the system effectively removes bacteria and viruses from the air, ensuring clean exhaust.

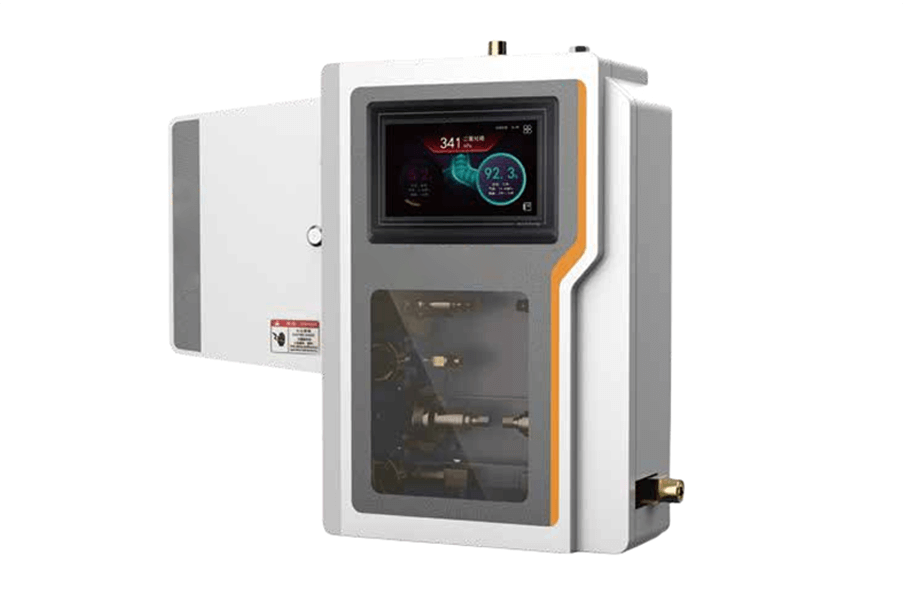

Intelligent Control System

The equipment features a PLC intelligent control system that monitors operational status in real-time. With touch screen and remote control capabilities, it ensures safety and efficiency.

Redundant Design and Reliability

The system employs redundancy configurations such as one-on-one backup, two-on-one backup, and three-on-one backup to ensure continuous operation under any circumstances, preventing any interruption during medical procedures.

Frequently Asked Questions

1. What is the maximum vacuum capacity of the medical vacuum system?

Answer: Our medical vacuum system offers a maximum vacuum level of -0.087MPa, meeting the needs of hospitals and medical institutions for large-scale suction support, ensuring sufficient negative pressure in both emergency and routine situations.

2. How do you ensure that no harmful substances are released during the exhaust process?

Answer: The system is equipped with a four-stage exhaust sterilizer, combining high-precision filtration, UV ozone sterilization, and photocatalysis to effectively remove bacteria, viruses, and particles from the exhaust, ensuring that the discharged air meets hygiene and safety standards.

3.How is a system failure handled?

Answer: Our vacuum system is designed with redundancy (one in use, one as backup). If the main unit fails, the backup unit automatically takes over, ensuring the system continues to operate without interruption.

4. Is the system maintenance difficult?

Answer: The system is designed for ease of maintenance with an intelligent PLC control that automatically monitors operation and alerts for maintenance needs. Components such as filters and valves are easy to replace, and the system includes self-diagnosis functions to simplify upkeep.

5. What is the lifespan of the vacuum pump?

Answer: With proper maintenance, the vacuum pump typically lasts over 10 years. We recommend regular inspection and filter replacement, along with scheduled servicing, to ensure long-term, efficient operation.

6. How does the system maintain stable operation in high-demand environments?

Answer: Our system utilizes an oil-lubricated rotary vane vacuum pump combined with a storage tank and bacterial filter, ensuring stable performance under varying loads, providing continuous suction support in critical areas such as operating rooms and ICUs.

7. Can the system be customized based on hospital requirements?

Answer: Yes, we offer tailored solutions that can adjust suction capacity, equipment configuration, and functionality according to hospital size, departmental needs, and available space, ensuring optimal performance for your specific requirements.

Optional Configurations

Bacteria filters

Vacuum tank

Oxygen Therapy

Tank Gas Separator

Standard configuration and features of our products

A standardized medical vacuum negative pressure unit typically includes an electrical control cabinet, vacuum pump, air assembly, frame (enclosure), internal pipelines, and valves. Components such as bacterial filters, vacuum tanks, exhaust sterilizers, gas separation cylinders, and interconnecting pipelines and valves are separate modular units and optional accessories.

The standard electrical control includes PLC, remote computer control, mobile app, sterilizer contacts, automatic power recovery function, and backup electrical components. 485 communication and GSM are optional modules.

The unit operates within an environmental temperature range of 0–40°C. For special temperature requirements, please contact our technical team.

The power of individual machines and the configuration of the unit are based on standard specifications. Custom configurations can be discussed with our technical team.

Cost Accounting

We have a professional technical team, come and compare prices and services

*Required fields to better serve you.

We do not share your personal information with third parties. By clicking the button, you consent to the processing of personal data.

sales2:+86 17506119168

sales2:+86 17506119168