By closely collaborating with our client in the Dominican Republic, we successfully delivered 40 PSA oxygen generators with capacities of 6m³/h, 12m³/h, and 20m³/h. Through precise customization, the use of high-end international components such as Siemens PLCs and UOP molecular sieves, and a transparent production process, we earned their trust. We provided rapid response, custom design, and seamless logistics support to ensure the equipment’s stable performance, with oxygen purity at 95%±1%. Following the completion of the initial order, the client immediately placed an additional order, showcasing their high level of confidence in the quality and service of MINNUO.

Background

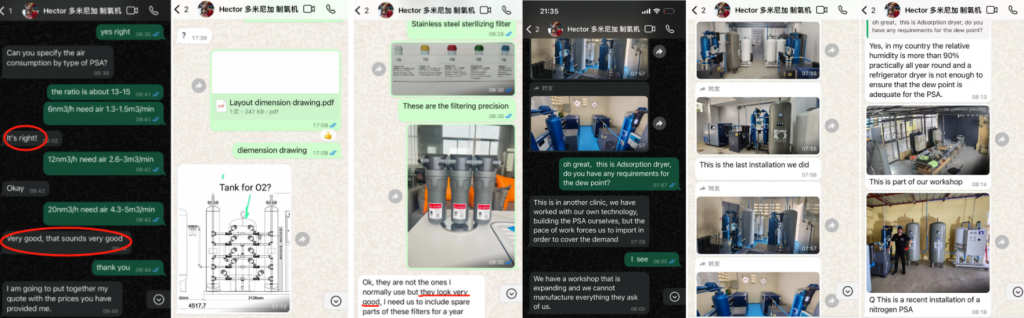

It all began in early 2024, when a Dominican company known for PSA oxygen and nitrogen generators reached out to us. Due to a heavy production load, they were unable to deliver a significant order on time. They needed a technically proficient and reliable partner to handle the OEM production of 40 6m³/h, 12m³/h, and 20m³/h PSA oxygen generators.

Technical Co-Creation: Building Trust Through Expertise

Parameter Recommendations

Based on their usage scenarios and installation conditions, our gas equipment technology team provided precise parameter suggestions:

- 6m³/h PSA Oxygen Generator: Configured with a 1.3-1.5 m³/min air compressor, optimized air consumption ratio of 13:1, and power control under 7.5 kW.

- 12m³/h PSA Oxygen Generator: Configured with a 2.6-3.0 m³/min air compressor, air consumption ratio maintained at 14:1, and actual power of 15 kW.

- 20m³/h PSA Oxygen Generator: Configured with a 4.3-5.0 m³/min air compressor, optimized air consumption ratio of 15:1, and power of 22 kW.

High-End Component Configuration

We shared the logic behind the selection of key components with our client, such as:

- Siemens PLC Control System: Ensuring stable operation while meeting the client’s expectation for intelligent control.

- UOP Molecular Sieve (USA): Improving long-term stability of oxygen purity and extending the molecular sieve’s lifespan.

- Upgraded Filtration System: Adding a stainless steel bacteria filter to effectively filter 99.99% of bacteria and impurities, providing cleaner, safer oxygen to end-users.

Design Optimization

The client was concerned about the equipment size possibly affecting installation. We immediately gathered on-site data from the client and completed an optimized design within 48 hours, with the following dimensions:

- 6m³/h PSA Oxygen Generator: 1200mm × 800mm × 1800mm

- 12m³/h PSA Oxygen Generator: 1600mm × 1000mm × 2000mm

- 20m³/h PSA Oxygen Generator: 2000mm × 1500mm × 2100mm

After confirming the design, we used a model demonstration for further communication, ensuring the design met their real-world requirements, enhancing usability, and reducing transport and installation costs for the client.

Service Synchronization: Seamless Collaboration with the Client

Efficient Response

The client’s initial contact was in the early hours of the morning. Despite the unusual timing, we responded within an hour and provided a detailed quote within 12 hours, ensuring that they received necessary information promptly. During the technical discussion phase, we maintained quick and accurate answers to every question (e.g., PLC functionality, filter performance), with an average response time under 24 hours.

Transparent Production Process, Real-Time Progress Updates

To provide full reassurance to our client, we established a transparent production process and kept them updated through weekly reports:

- Week 1: Completed the structural framework and confirmed the design with the client.

- Week 2: Installed core components and performed oxygen purity tests, sharing the 95%±1% data in real time.

- Week 3: Painted and customized logos; executed upon client approval of mockups.

- Shipping Phase: Recorded performance testing of finished products, ensuring each unit met the client’s requirements, and photographed packaging details for transportation safety.

The client was thoroughly informed at each stage, being both a participant and a driver of progress, which further strengthened our mutual trust.

One-Stop Logistics Support

For shipping, we prepared all customs clearance documents in advance (including commercial invoices, certificates of origin, and quality inspection reports) and utilized high-standard wooden crates to ensure safe transport. We also arranged for a professional logistics team to track shipment status in real time, offering peace of mind to the client.

Order Details

- Initial Order Delivery: The 20 units of 6m³/h oxygen generators were delivered on time, passing on-site testing with stable operation and oxygen purity maintained at 95%±1%. The client feedback was, “The performance and service of the product exceeded our expectations.”

- Trust Built for Additional Orders: Less than two weeks after the initial collaboration, the client placed an additional order for 20 units of 12m³/h oxygen generators and made an advance payment, demonstrating high confidence in our service and quality.

- Foundation for Long-Term Collaboration: Even before their end-users completed facility construction, the client was highly satisfied with the equipment quality just from unpacking inspection. The client shared, “From data to service, MINNUO is the most trustworthy partner we have.”

Conclusion

MINNUO consistently works hand-in-hand with our clients, using professional expertise and superior service to help them achieve their goals:

- Parallel Technical Collaboration: From design to testing, each step involves close cooperation, jointly defining product value.

- Synchronized Service Experience: Whether in transparent production or logistics support, the client always feels a strong sense of participation and control.

- Co-Creation and Shared Success: We not only completed a successful delivery but also laid the foundation of trust for future projects.

Looking forward, we are eager to partner with more clients, jointly driving industry growth and innovation. MINNUO—always by your side.

sales2:+86 17506119168

sales2:+86 17506119168