With the widespread use of PSA oxygen systems, the twin tower cycle operation has become a key design element to improve oxygen production and stability. This article will discuss in detail how the twin-tower cycle works and its importance in PSA oxygen systems.

A common question asked by many users is why oxygen system design requires a dual tower rather than using a single tower system. Although simple, a single tower design cannot achieve the efficiency and stability of a dual-tower system. The dual-tower cycle design alternates adsorption and regeneration between the two adsorption towers, thus ensuring continuous and stable operation of the system and providing a constant supply of high-purity oxygen.

In this paper, we will analyze the core working principles of the dual-tower cycle design, including how it improves system efficiency, extends equipment life, and provides a constant and stable oxygen output. At the same time, we will explore why dual-tower systems have advantages over single-tower designs in real-world applications, especially in industrial and medical scenarios.

I. Basic Concepts: What is Twin Tower Cycle Operation?

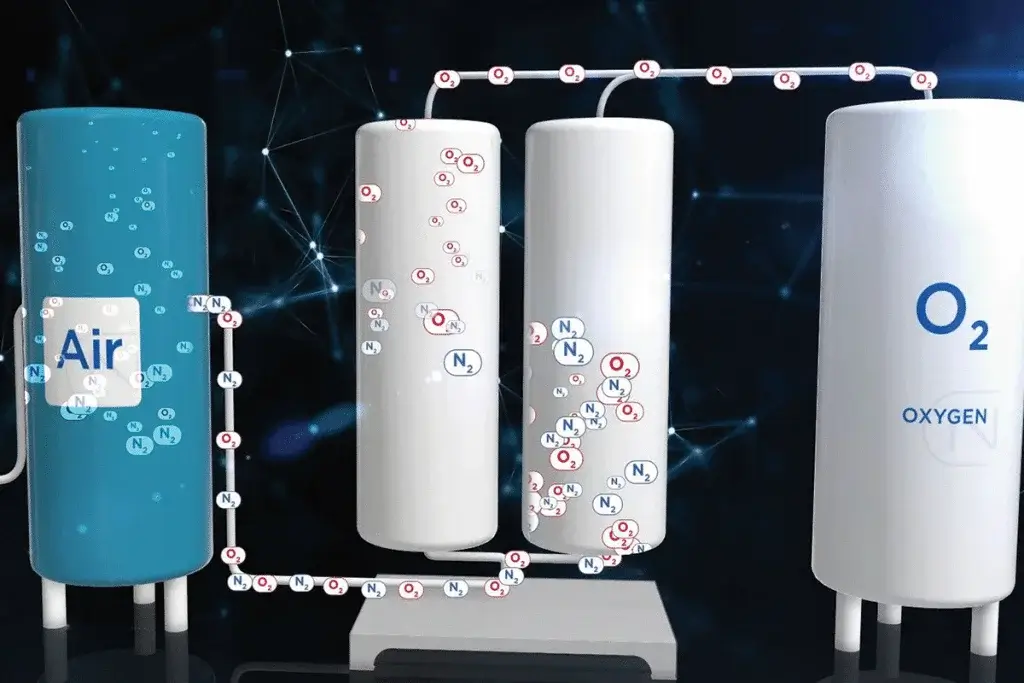

In PSA (Pressure Swing Adsorption) oxygen generation system, dual tower cyclic operation is a classic and efficient structural design, the essence of which is to achieve a coordinated balance between continuous oxygen production and adsorbent self-regeneration through the alternating operation of two adsorption towers.

✅ Definition of Dual-Tower System

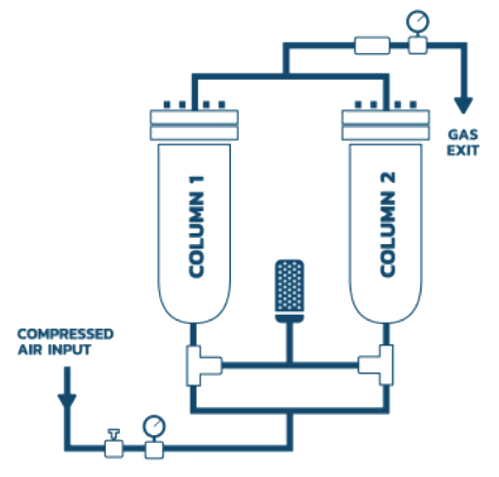

The dual-tower system consists of two adsorption towers of the same size, numbered tower A and tower B, respectively. At any moment, the system allows only one adsorption tower to be in working condition (responsible for adsorbing nitrogen in the air and outputting oxygen-enriched body), while the other one enters into low-pressure regeneration state, discharging the adsorbed nitrogen through pressure release, thus restoring the adsorption capacity of the molecular sieve.

Brief operation process

The whole operation process is a cyclic cycle, which can usually be expressed in the following steps:

Adsorption (tower A) → switching valve → regeneration (tower A) → adsorption (tower B) → … cyclic cycle

Each cycle lasts for several tens of seconds to several minutes;

The switching process is accurately controlled by the PLC control system, which is usually completed in less than 1 second, and is imperceptible to the user.

Intuitive difference with single tower system

| Item | Twin-tower system | Single tower system |

| Operation mode | Adsorption + regeneration alternating, continuous operation | Must stop for regeneration after adsorption |

| Oxygen output continuity | Realize 24-hour continuous oxygen supply without interruption | Oxygen supply is not continuous, easy to interrupt and affect the gas-using equipment |

| Adsorbent life | Load-sharing, recycling, longer service life | Long-term heavy-load operation, adsorbent is easy to fail |

| Application adaptation scenarios | Scenarios for medical, industrial, and continuous operation requirements | Suitable only for scenarios that do not require a high degree of continuity or temporary oxygen use. |

The double-tower cyclic operation mechanism not only improves the stability and efficiency of the system operation, but also significantly enhances the continuity of oxygen supply, which is the standard configuration of modern medium and high-end PSA oxygen generating equipment, and is especially suitable for hospitals, laboratories, electronic manufacturing and other applications with extremely high requirements for oxygen continuity and purity.

Ⅱ.The core significance of double-tower cycle operation analysis

The application of twin tower cycle operation in PSA oxygen generation technology greatly improves the stability and efficiency of oxygen supply, and ensures the continuous and long-term stable operation of the equipment. In this system, two adsorption towers run alternately, making the oxygen production process uninterrupted, which meets the high standard of high purity and stable oxygen demand. In the following, we will analyze the four core significance of the dual-tower cycle:

2.1 Ensuring Continuous and Stable Oxygen Output

One of the core advantages of the dual-tower system is the ability to ensure continuous and stable oxygen output. By alternating adsorption and regeneration, the working cycle time of each tower is precisely controlled to ensure that during the regeneration of one tower, the other tower is working normally, thus avoiding the interruption of oxygen due to system downtime.

This uninterrupted continuous gas supply enables the equipment to continuously provide users with the required oxygen concentration, and can be adapted to hospitals, industrial production and other high-continuity demand scenarios.

2.2 Improve the precision of oxygen concentration and purity control

The alternating function of the twin-tower system not only maintains stability in oxygen output, but also precisely controls oxygen concentration and purity. During operation, the system will automatically adjust the operating parameters according to the set target value (e.g. 93% ± 3%) to ensure that the oxygen concentration is always within the standard range.

This high-precision concentration control is crucial for some applications that require high oxygen purity, especially in medical and laboratory fields. It helps users to avoid safety hazards caused by concentration fluctuations when using oxygen.

2.3 Extend the service life of the equipment

The working load of the adsorbent is reasonably distributed in the dual-tower system, and the two towers work alternately to avoid the prolonged overuse of a single tower, which effectively reduces the excessive depletion of the adsorbent. At the same time, the cyclic regeneration reduces the continuous pressure of the equipment, minimizes the wear and tear, and extends the service life of the equipment.

Compared with the traditional single-tower system, the double-tower cycle can reduce the occurrence of equipment failures, reduce downtime, and ensure that the equipment can operate stably for a long time.

2.4 Reduced energy consumption and improved system efficiency

The dual-tower recirculation system achieves a higher energy efficiency ratio during operation. As the adsorption and regeneration processes are fully optimized, the system makes more efficient use of compressed air and reduces unnecessary energy waste.

Compared with traditional PSA systems, the dual-tower system not only improves the efficiency of oxygen generation, but also reduces the energy loss caused by frequent switching of the equipment, helping users to obtain a more stable oxygen supply while reducing operating costs.

By effectively utilizing the alternating adsorption and regeneration functions of each tower, the dual-tower cyclic operation system ensures a continuous supply of oxygen and high purity output. It optimizes the operational efficiency of the system by reasonably distributing the load, extending equipment life, and reducing energy consumption at the same time, making it an ideal choice for high-demand, high-purity oxygen equipment, especially for hospitals, industry, pharmaceuticals and high-demand environments.

Ⅲ. Analysis of User Concerns and Misconceptions

When purchasing and using a double-tower circulation system, many users may have some misunderstandings or concerns about its use. The following are common user questions and misconceptions analyzed to help users fully understand the advantages and application scenarios of the dual-tower system.

3.1 Why can’t I just use a single-tower system?

Misconception Analysis:

Some users believe that using a single-tower system can simplify the equipment structure and reduce costs. However, single-tower systems actually have greater problems with stability and continuity, especially in application scenarios that require a long-term stable supply of oxygen, such as hospitals or industrial applications.

Since single-tower systems can only switch between adsorption and regeneration, oxygen cannot be supplied during the regeneration phase, resulting in unstable system operation.

Core problem:

The oxygen supply of a single-tower system is interrupted during regeneration, which seriously affects the continuity and stability of the oxygen supply. The dual-tower system, however, ensures a continuous supply of oxygen by alternating adsorption and regeneration, solving the shortcomings of the single-tower system.

3.2 Isn’t the twin-tower system more complicated and easier to break down?

Misconception Analysis:

Although the dual-tower system is structurally more complex than the single-tower system, it actually has greater advantages in improving equipment reliability and extending service life.

The design advantage of the dual-tower system lies in its ability to ensure that each tower is adsorbed and regenerated at different points in time during the alternating operation of the two towers, which not only ensures the continuous operation of the system, but also effectively avoids over-fatigue of the equipment and prolongs the service life of the equipment.

Core issues:

The dual-tower system is designed to be more compatible with the need for long and stable operation, and it can still provide an efficient and stable supply of oxygen, even in complex working environments. Its structural design does not lead to a more complex system, on the contrary, the actual operation and maintenance become easier through intelligent functions such as PLC control system.

3.3 Will the switching of dual towers cause unstable gas output?

Misconception analysis:

Some users worry whether the dual-tower system will affect the stability of oxygen during the switching process of adsorption tower. Gas fluctuation during switching is a common problem in all twin-tower systems, but it can be avoided by scientific design and efficient control system.

The core problem:

The switching process of the twin-tower system is optimized, especially in the regulation of gas flow and pressure, and the alternate switching of the twin towers can smooth the transition and avoid the instability of oxygen concentration. In addition, modern twin-tower systems are often equipped with concentration monitoring and alarm systems so that users do not need to worry about the instability of the outgoing gas during use.

Ⅳ.Practical Application Cases of Twin-tower PSA System

As an efficient gas separation technology, twin-tower PSA system has been widely used in various industries. The following are some typical application scenarios and their advantages:

4.1 Medical Central Oxygen System (ICU/Ward Continuous Oxygen Supply Guarantee)

Application Background:

In hospitals, especially in ICUs (Intensive Care Units) and wards, the stability and reliability of the oxygen supply is of paramount importance. Patients need a long and stable supply of oxygen, and any interruption or instability in the supply of oxygen may pose a threat to the safety of patients’ lives.

Advantages of Twin-tower PSA System:

Stable and Continuous Oxygen Supply: Twin-tower PSA system ensures a stable and continuous supply of high-purity oxygen at any moment by alternating adsorption and regeneration in two towers, avoiding any interruption of oxygen supply that may occur in a single-tower system.

Adaptable to high flow demand: The demand for oxygen in medical places is large and constantly changing, the dual-tower system can adjust the supply flow according to the actual demand to meet the needs of different wards and equipments.

High purity assurance: The twin-tower PSA system can ensure that the oxygen concentration is kept within the medical standard range of 93±3% for a long time, which ensures the therapeutic effect of patients.

4.2 Electronics Manufacturing Industry (Requirement of High Purity Continuous Oxygen Supply)

Application Background:

In the electronics manufacturing industry, especially in semiconductor production and precision electronic device manufacturing, the purity of oxygen is required to be extremely high, and a long-term stable supply needs to be guaranteed in order to support the complex production process.

Advantages of Twin-Tower PSA System:

High Purity Oxygen: Twin-tower PSA system can precisely control the concentration of oxygen to ensure the provision of high purity (more than 90%) oxygen, to meet the electronics industry’s strict requirements for oxygen purity.

Continuous and stable oxygen supply: the system can operate stably under all-weather working conditions, providing stable oxygen supply for the production line and guaranteeing the continuity of production.

Energy saving and consumption reduction: the efficient operation mode of the double-tower system effectively reduces energy consumption and operating costs while meeting the demand for high-purity oxygen.

4.3 Aquaculture (All-weather constant-temperature oxygen-supplying aquaculture tanks)

Application Background:

In the aquaculture industry, the healthy growth of fish and other aquatic organisms requires an adequate supply of oxygen. Insufficient oxygen will lead to deterioration of water quality and affect the aquaculture efficiency. Therefore, there is a need for an efficient and stable oxygen supply system, especially under high water temperature.

Advantages of the Twin-Tower PSA System:

Constant Oxygen Supply: The Twin-Tower PSA System is able to continuously supply the aquaculture tanks with the required oxygen 24 hours a day, 7 days a week, to ensure that the dissolved oxygen level in the aquaculture environment is always in an ideal state.

Adaptation to harsh environments: The twin-tower system operates stably in high temperature and high humidity environments, and is not disturbed by changes in the external environment, which greatly improves the durability and adaptability of the equipment.

Energy saving and environmental protection: Compared with the traditional oxygen production method, the twin-tower PSA system consumes less energy and reduces the farming cost due to the adoption of highly efficient oxygen separation technology in the system.

4.4 Emergency Oxygen Supply for Plateau Construction Sites (High-flow and Stable Output)

Application Background:

Due to the thin oxygen and difficult working environment in the plateau region, construction workers and equipment on construction sites often face the problem of insufficient oxygen. At this time, a high-flow, stable output oxygen supply system is especially important.

Advantages of Twin Towers PSA system:

High flow rate output: Twin Towers PSA system can provide high flow rate and high stability of oxygen supply, which can meet the high demand of oxygen on the plateau construction site.

Stability: The continuous operation of the system ensures the stability of the oxygen supply and avoids the gas fluctuation problems common in other oxygen production methods.

Plateau Resistance: The design of Twin-Tower PSA system takes into account the special needs of plateau area, which can adapt to the harsh environment of low oxygen and high altitude to ensure the normal operation of workers and equipments.

V. Recommended MINNUO Oxygen Generation Solutions

MINNUO offers a range of PSA oxygen generation systems for industrial and medical applications, designed to meet the supply of oxygen for a variety of needs. The following is a detailed analysis of the advantages and features of MINNUO solutions.

5.1 Comprehensive dual-tower operation design

Core Benefits:

The MINNUO oxygen generation system utilizes a dual-tower recirculation design, which alternates adsorption and regeneration between the two adsorption towers to ensure continuous and efficient system operation. This design ensures continuous and efficient operation of the system by alternating adsorption and regeneration in the two adsorption towers. Compared to a single-tower system, the dual-tower design avoids interruptions in the system and increases the stability and reliability of the oxygen supply.

Technical details:

Dual tower alternating operation: one tower adsorbs and the other regenerates, minimizing downtime and ensuring a continuous supply of oxygen.

Stability: The design ensures an adequate supply of oxygen at all times and avoids airflow fluctuations that can occur with single-tower systems.

High efficiency: Due to the double-tower design, each stage can be fully utilized, thus improving the production and quality of oxygen.

5.2 Equipped with international brand molecular sieve and high-frequency air compressor

Core Advantages:

MINNUO’s oxygen production system uses international famous brand molecular sieve and is equipped with high-frequency air compressor to ensure high purity and high efficiency of oxygen production.

Technical details:

Molecular sieve: International famous brand molecular sieve is selected, which has good adsorption capacity and long time stability to ensure that the oxygen concentration reaches 93±3% standard.

Air compressor: High-frequency air compressor provides stable air compression, ensures the stability of gas flow and pressure, and optimizes the oxygen separation process.

High quality guarantee: MINNUO ensures the efficient and stable operation of the whole oxygen production system by choosing first-class molecular sieve and air compressor.

5.3 Provide customized design to meet different application requirements

Core Advantages:

MINNUO provides customized design services according to different customer needs, and flexibly adjusts the system configuration to meet the requirements of various special application environments.

Technical details:

Flexible Configuration: Whether in medical, industrial or highland environments, MINNUO can provide customized oxygen generation solutions.

Adaptability: The flow rate, pressure and oxygen concentration of the system can be adjusted to meet the needs of different industries.

High-end customization: Provide personalized customization services for high-end applications, including equipment appearance, functional configuration, operation mode and other aspects.

5.4 High-efficiency, energy-saving, low-maintenance, lower operating costs

Core Advantages:

MINNUO’s oxygen generation system is designed to focus on high-efficiency and energy-saving, which can maximize the reduction of operating costs, while at the same time reduce the need for maintenance, and extend the service life of the equipment.

Technical details:

Energy efficient operation: The system is optimized to reduce energy consumption while ensuring efficient gas production, reducing long-term operating costs for the user.

Low Maintenance: The use of high-quality materials and technology, equipment failure rate, low maintenance costs, suitable for long-time continuous operation.

Cost-effective: Compared with other similar products, MINNUO’s oxygen generation system not only has high efficiency, but also can significantly reduce the operating costs of enterprises.

5.5 Meet the oxygen demand of various applications

Core Advantages:

MINNUO oxygen generation system is widely used in many industries, and can provide customized oxygen solutions to meet the oxygen demand of different industries and places.

Technical details:

Medical industry: Provide stable and continuous oxygen supply for hospitals, clinics, ICUs, etc., to ensure the safety of the medical environment and the health of patients.

Industrial applications: In electronic manufacturing, chemical industry, metallurgy and other fields, MINNUO provides high-purity oxygen to ensure the continuous and stable operation of production lines.

Plateau area: Adapt to the harsh environment of plateau and mountainous area, provide stable oxygen supply to ensure the safety of work in high altitude areas.

MINNUO oxygen system provides high quality oxygen solutions for different industries through the efficient and stable double tower PSA design, international brand molecular sieve, intelligent control system and customized service. Whether it is medical, industrial or special environmental applications, MINNUO can ensure to provide users with high efficiency, low energy consumption and low maintenance oxygen systems, optimize production efficiency and protect users’ safety.

Conclusion

The twin-tower cycle is not only an innovation in structural design, but also a core guarantee of continuity, reliability and durability for PSA oxygen systems. By alternating the operation of the twin towers, the system is able to work in a balanced manner in different adsorption and regeneration phases, which ensures the stability of oxygen production and quality, and is the key to meet the long-term continuous and efficient demand.

For users of medical and industrial applications who are in pursuit of long-term and stable oxygen production, a high-quality twin-tower PSA system is a trustworthy choice.MINNUO brand gas equipment, with its advanced twin-tower design and efficient and stable system performance, always provides users with high-quality, energy-saving and high-efficiency oxygen and nitrogen solutions to meet the high requirements of different demand scenarios.

sales2:+86 17506119168

sales2:+86 17506119168