At a time when public health emergencies are frequent – whether it is the recurrence of new crown epidemics, earthquake disasters, regional conflicts, or the increase in hospitalization rates for chronic diseases in an aging society – the healthcare(PSA) system poses an unprecedented challenge to a “stable, continuous, and high-purity” supply of oxygen. Oxygen, as an indispensable life resource in critical care, ICU respiratory treatment, surgery and anesthesia, its safety and security has become the core of the efficient operation of the modern medical system.

However, the traditional oxygen security model has multiple hidden dangers: heavy reliance on the transportation of liquid oxygen reserves, frequent and limited supply of bottled oxygen, and once the transportation is interrupted or the supply chain around the hospital is broken, it may cause oxygen shortage in ICU and other key areas, threatening the safety of patients’ lives. In front of the reality of “can’t wait” and “can’t cut off supply”, hospitals urgently need to establish a more independent, reliable and scalable oxygen system.

In this article, we will focus on PSA medical oxygen system, comprehensively explain its working principle, technical advantages, and typical application value in major emergency scenarios such as epidemics, earthquakes, etc., and reveal why it is becoming a key solution for more and more medical institutions to build “oxygen safety bottom line”. It reveals why it is becoming a key solution for more and more medical organizations to build “oxygen safety bottom line”. If you are concerned about the enhancement of hospital oxygen supply capacity, and hope to reduce the risk of oxygen under emergency events, this paper will provide you with a set of practical references that emphasize both technology and strategy.

Ⅰ.The core challenges of emergency medical oxygen guarantee

In public health emergencies (such as epidemic outbreaks, earthquakes, fires, large-scale accidents), medical oxygen is not only a basic life-supporting means, but also the “first lifeline” for rescuing critically ill patients. However, in reality, the oxygen supply security system has exposed various risks, mainly focusing on the following three aspects:

1. Supply chain risk: heavy external dependence, uncontrollable transportation

Dependence on liquid oxygen supply chain is too heavy: most hospitals deliver liquid oxygen storage tanks through external suppliers, and once there is an interruption in the logistics (e.g., road collapses, city closures, war blockades), the supply can not be replenished in time, resulting in the exhaustion of the oxygen source.

Difficulties in transportation in disaster areas: earthquakes, floods and other disasters may lead to transportation paralysis, oxygen cylinders and liquid oxygen tankers can not enter the core area, especially in the plateau, alpine and other special environments such as transportation radius is more restricted.

Long transportation cycle and limited inventory: Oxygen cylinders or liquid oxygen tanks need to be replenished on a regular basis, and the general time limit for hospitals to be available is 1~2 days, which makes it very easy to cut off the supply once the dosage surges.

✅ Sublimation point: traditional centralized oxygen supply is difficult to cope with multi-point outbreaks and sudden situations, emphasizing the need to deploy “on-site oxygen production”.

2. Management and deployment pressure: peak oxygen consumption exceeds the carrying capacity of the existing system

Unbalanced oxygen consumption structure: ICU beds expand during emergencies, emergency, anesthesia, respiratory and other key departments focus on oxygen consumption, the original pressure regulator system pressure soars, and it is very easy to drop pressure and cut off the supply, etc.;

Cylinders are frequently switched and manpower dispatch is insufficient: during the peak period of consumption, the number of times oxygen cylinders are changed per day may be more than 10, which is a great pressure on the medical and nursing care and logistics, and there are manual failures. The pressure on logistics is extremely high, and there is a risk of manual error;

Information asymmetry and lagging response: some hospitals still use manual oxygen scheduling table, which can’t grasp the trend of oxygen consumption and alarm signals in real time, delaying the replenishment time.

✅ Sublimation point: Relying only on “manpower rotation” and “emergency response after the fact” is no longer suitable for modern high-load hospital operation, and an automated, monitorable and early warning oxygen supply system should be established.

3. Hospital clinical oxygen load fluctuates drastically: challenges to system responsiveness and stability

Large load fluctuation: for example, at the beginning of the epidemic, the oxygen consumption of some square pods or ICU wards of tertiary hospitals increases by dozens of times, especially at the stage of intensive treatment of intubated patients, which puts the capacity of the equipment and the speed of response to the severe test;

High stability requirements: respiratory therapy, anesthesia and surgery, negative-pressure wards, and other scenarios require a stable concentration of oxygen and a continuous supply of oxygen, any pressure fluctuation or concentration deviation. Any pressure fluctuation or concentration deviation may cause patient risk;

Oxygen concentration requirement is controllable: special diseases such as neonates, postoperative cardiac patients, etc., need to be accurately controlled in the range of 93%±3%, which is difficult to meet the standard stably with traditional bottled oxygen.

✅ Sublimation point: In a high-density oxygen environment, the system not only needs to be “able to supply”, but also needs to be “stabilized”, and the advantages of PSA system’s purity control and automatic pressure regulation are highlighted.

As the frequency of public health emergencies rises, the traditional oxygen supply method is facing “system-level challenges”, which exposes serious shortcomings in the high-load, sudden, multi-point synchronized oxygen environment. PSA medical oxygen system is becoming an important solution for all kinds of hospitals and emergency platforms to improve medical resilience due to its core advantages such as “local independent oxygen supply, stable purity, fast response and intelligent management”.

Ⅱ.The working principle and technical advantages of PSA medical oxygen system

In the emergency and routine medical environment, PSA (Pressure Swing Adsorption) oxygen technology is gradually becoming the mainstream solution, which is widely deployed in ICU wards, hospitals and remote healthcare centers due to its outstanding advantages of rapid response, safety and stability, and no need to rely on external liquid oxygen supply, Hospitals and health stations in remote areas.

1. Brief introduction of basic working principle

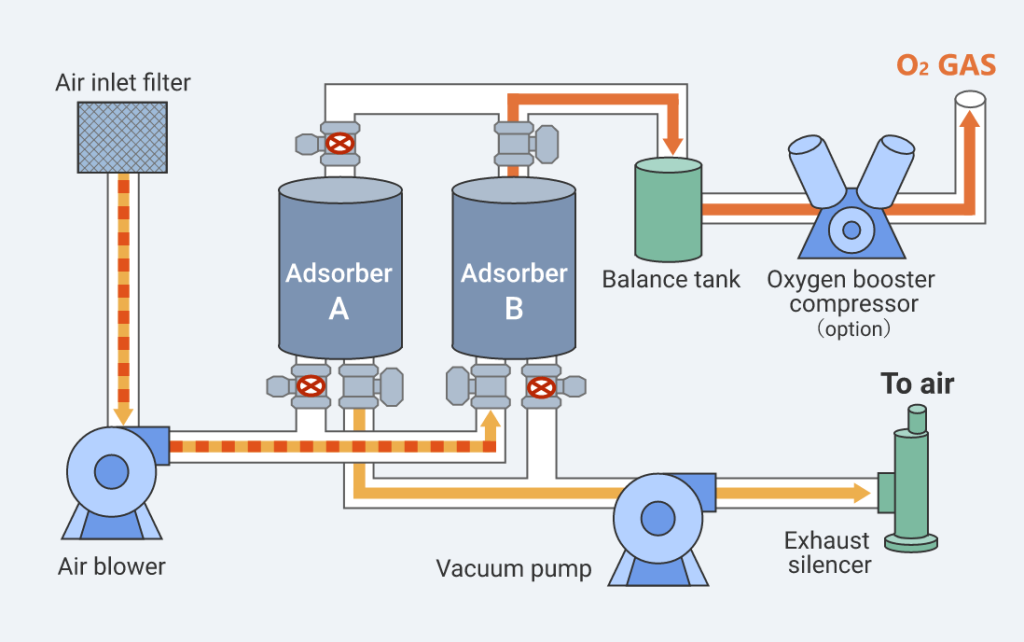

PSA technology utilizes the difference of adsorption capacity of molecular sieve to each component in air under different pressure conditions, adsorbs nitrogen in air under pressurized condition, leaving behind the oxygen-rich body; and releases the adsorbed nitrogen under depressurized condition to regenerate molecular sieve, realizing the cyclic process of continuous oxygen production.

Raw gas: directly taken from the surrounding air (no need to purchase outside)

Produced gas: the purity of oxygen is usually ≥93% and stabilized at 93% ±3%, which is in line with the purity standard of medical oxygen in Chinese Pharmacopoeia.

✅ Sublimation Note: The oxygen production process is physical adsorption, does not depend on chemical reaction, no pollution, no waste liquid, and can be operated continuously.

2. System Key Technology Components

A standardized PSA medical oxygen generation system generally contains the following core modules:

| System Modules | Functional description |

| Air Compression Module (Air Compressor + Storage Tank) | Provide continuous and stable original gas source, filter large particles of impurities and oil-water separation; |

| PSA Adsorption System (Molecular Sieve Tower) | Run by two or more adsorption towers alternately to complete the process of nitrogen-oxygen separation and molecular sieve regeneration; |

| Oxygen Post-treatment Unit | Including dust filters, bacterial filters, voltage stabilizers, purity on-line monitors to ensure that the terminal oxygen in line with the medical standard; |

| Control System | PLC programmable automatic controller responsible for the system start-stop, flow rate adjustment, pressure switching and alarming. is used for storing finished oxygen and supplying it to ICU, wards and other terminal areas, which can be docked with the original pipeline network. |

| Oxygen Storage Tank + Oxygen Supply Connection | Functional description |

✅ Project description: In emergency deployment scenarios, the PSA system can realize containerized mobile arrangement or modularized disassembled construction, and can be up and running within 30 minutes.

3. Panoramic comparison of technical advantages

| Advantage Dimension | Description |

| ✅ Stand-alone operation | does not rely on liquid oxygen or cylinder gas supply, suitable for rapid deployment in closed places, remote areas and disaster sites; |

| ✅ Fast response | usually produces 93% stable medical oxygen within 30 minutes after start-up, adapting to the peak of unexpected patients; |

| ✅ Stable operation 24/7 | supports all-weather continuous oxygen production, avoiding the risk of interruptions caused by frequent replacement of oxygen cylinders or liquid oxygen replenishment; |

| ✅ Auto-tuning and remote control | supports PLC+touch-screen control, and remote monitoring of the purity, pressure, operating status and Support PLC+touch screen control and remote monitoring of purity, pressure, operation status and abnormal alarm; |

| ✅ Cost controllable | The operation cost is about 30% lower than that of liquid oxygen per cubic meter, which can reduce the frequency of logistic purchasing and transportation; |

| ✅ Module expandable | Flexible increase or decrease of modules according to the beds of hospital districts and the load of oxygen used by ICU, which is suitable for use in a single department or the whole hospital building; |

✅ Comparison Summary: Compared with traditional bottled oxygen and liquid oxygen, PSA oxygen system has the triple advantages of “local, nearby and fast”, which is a strategic oxygen protection facility to fight against epidemic outbreaks and to deal with large-scale casualty treatment.

Ⅲ.The practical application of PSA system in public health emergencies

In natural disasters, infectious disease outbreaks or sudden public health events, how to quickly and stably guarantee the oxygen supply of hospitals or field medical points is directly related to the rescue efficiency and life protection. PSA medical oxygen system has become an important infrastructure of domestic and foreign emergency response system due to its advantages of strong mobility, fast deployment, stable operation, etc.

1. COVID-19 Global Deployment during Epidemic

During the global new crown epidemic outbreak in 2020-2022, the traditional liquid oxygen supply was frequently interrupted, and many countries and regions quickly introduced PSA oxygen technology to establish the mechanism of “in-hospital oxygen generation + ICU fixed-point oxygen supply”.

Typical cases:

India, Indonesia, Nepal and other Southeast Asian countries, a number of square cabin hospitals and provincial hospitals, the use of modular PSA equipment, to achieve “rapid deployment + oxygen self-supply”;

The United States, Germany and other developed countries in the early stage of the epidemic synchronized with the establishment of vehicle-mounted mobile oxygen trucks, to cope with the expansion of ICU clusters and the plateau mountainous areas of the demand for oxygen supplementation.

✅Summary value: PSA system has the natural advantage of “non-dependence on external logistics, on-demand local oxygen supply”, which improves the independence and continuity of oxygen guarantee during the peak of epidemic.

2. Field Oxygen Supply in Earthquake/Extreme Climate

Natural disasters such as earthquakes, landslides, typhoons, floods, etc. often lead to road interruptions and obstruction of liquid oxygen transportation. At this time, the PSA module, which is “ready to use and does not need to rely on filling”, can be used to quickly establish “oxygen protection points” in disaster areas by means of vehicle, box or container.

Practical application scenarios:

Yunnan border defense mountainous area adopts “pickup truck + double adsorption tower” portable module to support township hospitals in the area above 3000 meters above sea level, solving the problem of inconvenient transportation;

During the flooding in Bangladesh, the water sanitation ship is equipped with small PSA unit to ensure the safety of oxygen therapy for respiratory infection patients for 24h.

✅ Arrangement highlights: PSA equipment can be adapted to field hospitals, square cabin wards, ICU expansion areas, and linked with solar energy or diesel generators to realize “power + oxygen source” independent closed-loop operation.

3. MINNUO project landing and program reference

As a total solution provider of emergency oxygen supply, MINNUO has been deeply engaged in the field of mobile and vehicle-mounted medical PSA system for a long time, and has landed high-performance equipments in many countries and regions.

Project Case Excerpts:

Middle East | Saudi Arabia, UAE National Medical Agency purchased MINNUO 20Nm³/h medical oxygen station, which is used to safeguard the wards of the regional general hospital and ICU beds;

Southeast Asia | Philippines metropolitan area to set up an intelligent containerized oxygen system, which meets the average daily 93% continuous output of pure oxygen, 24 hours a day without interruption;

✅ Deployment Advantage: MINNUO products support touch-screen control, remote diagnosis, system purity/pressure double alarm, widely applicable to mobile medical team, temporary square cabin, post-disaster recovery base and other high-response, high-security scenarios.

Ⅳ. Comparison and analysis with other oxygen supply methods

In public health emergencies or peak oxygen use scenarios, what kind of oxygen supply method to choose is directly related to the operation efficiency of hospitals, the success rate of patient resuscitation and the sustainability of logistic support. At present, the three common oxygen supply methods include PSA oxygen system, liquid oxygen storage tank and bottled oxygen, each of which has significant performance differences in terms of cost, response speed, continuity, safety, etc. The following table shows the three mainstream oxygen supply methods.

The following table is a comparative analysis of the key indicators of the three mainstream oxygen supply methods:

| Program | Cost | Speed of response | Continuity | Safety | Difficulty of operation and maintenance |

| PSA System | Medium (high initial investment, low long-term cost) | Fast, stable oxygen supply 30-60 minutes after startup | Can operate continuously | High (no high pressure storage) | Can be managed remotely/automatically |

| Liquid Oxygen Storage Tank | High (requires specialized transportation, filling, and storage equipment) | Highly efficient (but limited by frequency of transportation refills) | Dependent on external supply chain | Medium (low temperature and high pressure) | Cold chain requirements, complex maintenance |

| Oxygen Cylinders | High unit cost (most expensive per liter of oxygen) | Manual changeover required, slow response | Limited reserves, frequent replacements | Low (manual handling) | Frequent human involvement, inefficient |

Core Comparison Interpretation

1. Cost structure difference:

Although the initial purchase and installation cost of PSA system is higher, it does not need to purchase oxygen for a long period of time, and only electricity and air are needed for the operation process, so the long-term operation cost is much lower than liquid oxygen and bottled oxygen;

The cost of liquid oxygen and cylinder form is greatly affected by the fluctuation of market price, and it is not economically controllable.

2. Response speed:

PSA system takes only 30~60 minutes from startup to stable oxygen supply, which is especially suitable for emergency oxygen scenarios such as sudden ICU ward expansion and temporary ward activation;

Although liquid oxygen can be instantly accessed for oxygen supply, it needs to rely on transportation and filling, and the risk of sudden supply interruption is high;

Oxygen cylinder replacement relies on manual handling, which is a delayed response and unable to satisfy batch resuscitation scenarios.

3. Continuity guarantee ability:

PSA system can realize “24 hours a day” stable operation, suitable for coping with cyclical epidemics or continuous treatment in earthquake-stricken areas;

Although liquid oxygen has strong continuity, it cannot be self-sufficient in case of interruption of supply;

Oxygen cylinders need to be replaced frequently to maintain supply for several hours at most, which makes it difficult to guarantee large-scale continuous oxygen supply.

4. Safety dimension:

PSA system does not involve high-pressure liquid or explosive storage media, safer operation environment;

liquid oxygen is a low-temperature and high-pressure hazardous source, which requires strict management of cold chain storage;

oxygen cylinders have the risk of explosion/leakage, which is easy to cause safety hazards during transportation.

5. Convenience of operation and maintenance:

PSA supports remote monitoring and PLC automatic control, simple operation and maintenance, strong stability;

Liquid oxygen needs cold chain truck distribution + special person operation, which is not conducive to rapid deployment;

Oxygen cylinders need to be manually handled and switched, which is labor-intensive and inefficient.

Scenario Application Suggestions

| Application Scenarios | Preferred Oxygen Supply Options | Reasons why |

| Emergency ICU Bed Expansion | PSA Systems | Rapid deployment + continuous oxygen supply + automatic alarm |

| Field Hospital/Square Pod Centralized Admission | PSA Systems | Convenient for mobile deployment, remote operation and maintenance, support 24h continuous use |

| One-time High Volume Surgery/Intubation | Liquid Oxygen Storage Tanks | Immediate high-flow oxygen supply, suitable for planned surgical schedules |

| Short-Term Clinical Resuscitation/Mobile Care | Oxygen Cylinders | Flexible and portable, suitable for rapid transit, single emergency use |

Ⅴ.How to deploy PSA system scientifically to cope with emergency demand

In the face of high-intensity oxygen demand scenarios such as sudden epidemic, earthquake disaster or large-scale ICU expansion, the deployment of PSA medical oxygen system should not be “rushed” or “one-size-fits-all”. Scientific planning is needed in terms of actual oxygen consumption, flow fluctuation, equipment stability, system security and remote management to ensure that the system can respond quickly, operate efficiently and supply oxygen continuously.

1. Select the appropriate oxygen production

Oxygen production is the basic index of PSA system configuration, which must be combined with the number of beds in the ward, the proportion of critical illnesses, equipment redundancy and day and night peaks and valleys fluctuations of reasonable reserved space:

Recommended range: 5Nm³/h ~ 100Nm³/h (1Nm³ ≈ 1,000 liters of oxygen)

Calculation recommendations:

ICU wards are recommended to be equipped with ≥ 0.5 ~ 1Nm³/h for each bed;

Ventilator, Ventilator, intubation and other high-flow equipment need to be calculated by 1.5 to 2 times;

Comprehensive ward or fever clinic is recommended to be designed according to the peak of standby oxygen +20% redundancy.

✅ Case reference:

If 100 ICU beds are set up temporarily, it is recommended to configure PSA system with total oxygen production capacity of 50-80Nm³/h to ensure that oxygen supply is not interrupted in case of rapid expansion.

2. Reasonable supporting gas storage system

Although PSA system can realize 24h continuous operation, if there is power failure, equipment failure or overload of oxygen wave consumption, it is still necessary to equip gas storage device as emergency buffer:

Recommended gas storage strategy:

Oxygen tanks ≥2 times of the rated hourly gas production capacity, to ensure the continuous supply of oxygen for 30 minutes when there is a power outage or sudden pressure change;

Oxygen tanks should be equipped with automatic drains and safety valves to prevent damage to the tanks in high humidity environments; it is recommended to equip the tanks with automatic drains and safety valves to prevent damage to the tanks in high humidity environments. Oxygen storage tanks should be equipped with automatic drains and safety valves to prevent the tanks from being damaged by high humidity;

suggests the optional quick-connect interface to facilitate the switching of backup bottled oxygen or liquid oxygen replenishment system.

3. Perfect redundancy design and automatic switching mechanism

In order to ensure the continuity and safety of the system operation, it is necessary to make redundancy design on key equipment:

Redundancy of the electrical system: dual circuit UPS + diesel emergency power supply + high voltage protection mechanism;

Structure of adsorption tower: equipped with alternating operation mode of the twin towers, to avoid oxygen fluctuation;

Gas supply path: set up dual oxygen output interface, with automatic switching mechanism; Oxygen supply path: set up dual oxygen output interface, with automatic switching mechanism. Dual oxygen output interfaces with automatic switching function, once the main circuit is out of power/pressure, the backup circuit will be put into operation immediately.

✅ Technical note:

MINNUO medical PSA system adopts “power failure automatic switching solenoid valve + pressure interlocking gas supply” to ensure uninterrupted oxygen supply even if a single circuit fails.

4. Access to remote operation and maintenance management platform

High-intensity use scenarios, manual inspection is difficult to detect problems in a timely manner, it is recommended to access the intelligent remote operation and maintenance platform:

Platform features:

Real-time monitoring of the pressure, flow, purity, running time, alarm records;

Abnormalities are automatically pushed to the cell phone terminal of the administrator / scheduling platform;

Support docking with the central monitoring system of the hospital to realize the “intelligent operation and maintenance of the building level.

✅ Recommended platform:

MINNUO cloud platform supports “alarm linkage + data export + history curve + automatic diagnosis”, which is convenient for the operation and maintenance team of medical institutions to provide early warning and remote operation and maintenance.

5. Emergency Backup Power and Energy Supply System

In order to ensure uninterrupted operation of PSA system in power failure or outdoor scenarios, a multi-energy support solution should be designed:

diesel generator sets: supporting full-power 24-hour independent operation, suitable for fixed or field deployment scenarios;

photovoltaic + storage batteries: suitable for remote areas, rescue medical trucks, or zero-carbon hospitals, with environmental protection and sustainability;

power switching module: realizing automatic switching between utility-generator, with automatic switching within 3s of power failure. Power switching module: automatic switching between utility power and generator, seamless recovery within 3s of power failure.

Summarize the deployment model

| Module Dimension | Recommended Configurations |

| Core System | PSA mainframe + twin-tower adsorption system + PLC control system |

| Gas Storage System | ≥2 times gas production capacity stainless steel oxygen tank + quick connecting hose + pressure buffer valve |

| Redundant Design | electrical double circuit + automatic switching gas line + double pipeline |

| Intelligent Monitoring Platform | cloud alarm system + pressure/purity monitoring + remote visualization control interface |

| Emergency Power Supply | diesel power generation + photovoltaic battery switching system |

Conclusion

Under the background of frequent occurrence of public health emergencies and drastic increase of medical resource load, the stability, safety and response speed of medical oxygen supply have become one of the core indexes to measure the capability of medical emergency. Compared with the traditional “passive oxygen supply mode” of liquid oxygen and bottled oxygen which relies on external transportation, PSA medical oxygen system has become the preferred solution in emergency scenarios due to its advantages of localization, immediate supply and 24h continuous operation.

PSA system is not only suitable for ICU, negative pressure ward, respiratory specialties and other conventional high oxygen consumption departments, but also in epidemic prevention and control, earthquake rescue, mobile medical and other scenarios to show a strong adaptability, is the future of the hospital to build “self-supplied, safe, scalable” medical gas system is an important part.

As a professional provider of PSA medical oxygen solution, MINNUO is committed to providing high performance, rapidly deployable modular oxygen system for hospitals, emergency centers and government emergency platforms, supporting remote operation and maintenance, dual-channel redundancy, and clean and pure oxygen output, and helping users to realize the critical moment of oxygen production through the “integrated solution + intelligent monitoring platform”, which is the best solution to help users to realize the critical moment of oxygen production. Through the “integrated solution + intelligent monitoring platform”, it helps users realize stable oxygen supply, reduce loss and improve pressure resistance at critical moments, and has become an important choice for many medical systems to improve “oxygen toughness”.

sales2:+86 17506119168

sales2:+86 17506119168