With the ever-increasing requirements for medical support, industrial intelligence and environmental protection governance, oxygen systems have become indispensable core equipment in a number of key scenarios such as hospital ICUs, smelting furnaces, plateau sites and water treatment. Whether it is used to enhance the patient’s blood oxygen saturation, or to assist combustion to improve combustion efficiency, or to provide reaction conditions in the process of water purification and waste gas treatment, the stability and suitability of the oxygen system have a direct impact on the operational safety, production efficiency and service quality.

However, there are obvious differences in the technical principles, energy costs, flexibility and maintenance requirements of several common oxygen supply methods – liquid oxygen, bottled oxygen, on-site oxygen generation (such as PSA, VPSA, deep cooling method) on the market. Blind selection will not only cause equipment redundancy or insufficient performance, but also may bring operational burden, energy loss, and even affect the end-use effect. Therefore, a clear understanding of their own oxygen needs and scene suitability is the prerequisite for the development of cost-effective selection program.

This article will focus on the “application scenarios × technical principles × cost assessment × intelligent control × brand selection” five dimensions, systematically combing all types of oxygen equipment selection logic, to help hospital managers, industrial technicians and procurement decision makers to quickly establish a framework for scientific judgment, to avoid the waste of resources and operational risks caused by equipment selection errors. The five dimensions of “Oxygen Equipment Selection

1. Determine Application Scenarios

Before selecting oxygen equipment, it is important to first accurately identify the usage scenarios, as the requirements for flow rate, purity, control system, and structural form vary significantly from application to application. Wrong scene matching will lead to insufficient equipment performance or waste of resources.

Medical Scenarios: Stability and safety as the core

ICU intensive care unit, operating room, negative pressure ambulance: high purity (93%±3%) continuous oxygen supply is required, PSA medical oxygen system is recommended, equipped with dual-tower switching and concentration alarm function.

Community rehabilitation sites, small clinics: small demand for flow, can choose the integrated small oxygen concentrator, concerned about the footprint and ease of operation.

Industrial scenarios: gas production efficiency and adaptation to the environment is the key

Glass kiln, metallurgical combustion, welding oxygen supply: oxygen purity requirements ≥ 93%, it is recommended to use medium and large PSA or VPSA system, supporting buffer tanks to stabilize fluctuations.

Ozone reaction, environmental protection water treatment, pulp deinking and other occasions: the need for stable and continuous oxygen supply in the flow, control accuracy and operational stability is the focus.

Special environmental scenarios: it is more necessary to consider the adaptability of the equipment

Plateau/high temperature/high humidity/dust corrosive environments: it is recommended to use customized modular systems, such as plateau compressors, corrosion-resistant cabinets and anti-condensation structures.

Unattended site/remote area projects: It is recommended to choose intelligent oxygen generation equipment that supports remote monitoring and low maintenance frequency.

Difference in gas consumption cycle: decide system scale and investment

Emergency/temporary oxygen supply: such as disaster areas, field hospitals, sudden stopping of oxygen backup, it is recommended to choose vehicle-mounted or mobile all-in-one machine, supporting generator or UPS power supply.

Long-term/fixed oxygen consumption: such as continuous gas consumption in factories, centralized oxygen supply in hospitals, systematic solution is required, including oxygen generator, control, buffer, alarm, safety linkage and other sub-systems.

2. Core Selection Parameters

Oxygen equipment selection must be based on key technical parameters, different application requirements for purity, flow, pressure, operating mode and supporting conditions have strict requirements. The following is the analysis of the five core indicators:

Gas purity: 93%, 95%, 99.5%

Different oxygen purity directly corresponds to the technical path of the equipment and terminal applicability:

93% ± 3%: medical ICU, operating room standards, applicable to PSA medical oxygen generation system.

95% ± 1%: applicable to glass smelting, ozone system and other industrial medium and high end occasions, recommended industrial PSA/VPSA.

99.5% or more: experimental analysis, aerospace and aviation, high pressure oxygen cylinder filling and other high purity fields, need deep cooling or precision purification module support.

Gas flow unit: L/min and Nm³/h

Two kinds of units are used in different scenarios:

L/min (liter/minute): mostly used for single person oxygen, bed oxygen supply, portable equipment.

Nm³/h (standard square/hour): used in factories, hospitals, sites and other places, selection needs to be clear instantaneous peak demand.

✅ Conversion reference: 1Nm³/h ≈ 16.67 L/min

Selection suggestion: retain redundancy according to the maximum flow rate × 1.2, to avoid frequent start-stop or oxygen instability.

Using pressure range: 0.3~200bar

Pressure determines the back-end gas distribution and equipment matching options:

0.3~1.0bar: commonly used in hospital centralized oxygen supply, ozone system, auxiliary combustion and other scenarios;

10~30bar: applicable to bottled gas filling, industrial high-pressure oxygen;

100bar and above: high-pressure gas cylinder station, deep cooling gas station, etc.

✅ Configuration suggestion: matching buffer tank, regulator group, detection module to ensure downstream safety and stability.

Operation Mode: Continuous or Intermittent

24 hours continuous operation: such as hospitals, sewage plants, glass furnaces, etc., the equipment needs to be highly stable and low maintenance frequency;

Intermittent use: such as oxygen preparation, emergency use or laboratory scenarios, the selection of equipment focuses on the speed of startup and small footprint.

Power supply and environmental adaptability: Is the power supply stable? Can it be cooled by water?

Power conditions: Is there 380V three-phase power? Is it necessary to configure UPS uninterruptible power supply?

Environmental adaptability: high temperature/high humidity/dusty scenes are recommended to prioritize the selection of water cooling, dehumidification system, anti-corrosion design.

If in remote mountainous areas/islands, it is recommended to equip with diesel power generation + voltage stabilization system to ensure uninterrupted operation of equipment.

Comparison of Oxygen Generation Technologies

| Technology path | Principle | Applicable Scenarios | Advantages | Disadvantages |

| PSA (normal pressure adsorption) | Molecular sieve atmospheric pressure adsorption | Medical/Small and Medium Industries | Quick start, simple structure | Slightly higher energy consumption |

| VPSA (vacuum adsorption) | Vacuum + low pressure adsorption | Large Continuous Oxygen Supply | Energy saving, stable operation | High system complexity |

| Deep-cooling separation | Fractionation after air liquefaction | Large Steel Mills, Gas Sales | High oxygen purity | High investment and maintenance costs |

3. Evaluate Total Cost & ROI

The procurement of oxygen system equipment is not only a one-time investment, but also a comprehensive consideration of its operational life cycle cost (LCC). Reasonable evaluation of the initial investment and later benefits will significantly affect the sustainability and long-term economic benefits of the project.

Initial investment vs. long-term operation cost

Initial investment: equipment purchase cost, civil construction and installation, electrical support, commissioning and acceptance, etc.;

Long-term operation cost: electricity consumption (kWh/Nm³), labor, daily maintenance, and replacement of wearing parts;

Comparison logic: the cheaper the equipment, the higher the frequency of maintenance may be required; while the high-end equipment, despite the large initial investment, but energy saving + remote operation and maintenance can significantly reduce the cost of the later stage.

Life Cycle Cost (LCC) Model

LCC = Purchase + Installation + Energy Consumption + Maintenance + Labor + Spare Parts + Downtime Losses

It is recommended to evaluate the total cost during the project evaluation period (3~5 years), which is a more realistic reflection of the efficiency of inputs and outputs.

For example:

A high-efficiency VPSA equipment, with 20% annual power saving, is expected to recover the initial price difference in 3 years;

A deep-cooling equipment is stable, but the cost of a single failure maintenance can reach tens of thousands of dollars, which is not suitable for cash-strapped users.

Selection analysis using the ROI tool

Formula:

ROI (annual) = total initial investment / total annual cost savings

Savings can include:

replacement of liquid oxygen purchase cost

energy saving electricity cost benefits

reduction in maintenance man-hour cost

operational efficiency due to increased system automation

✅ MINNUO provides a proprietary ROI calculation tool, simply enter “oxygen flow, electricity price, operating hours”

4.System Reliability & After-Sales

The reliability of the system directly affects whether the oxygen supply can be “uninterrupted”. For critical application scenarios such as ICU emergency and smelting furnace continuous oxygen guarantee, stability and maintainability are especially critical.

Lifetime assessment of core components

Adsorption tower/molecular sieve: Is it ≥3 years? Can it be replaced and easily maintained?

Compressor/control cabinet: Does it support long time operation? Does it have anti-temperature/moisture design?

Vacuum pump/cooler: Is it equipped with oil seal protection or alarm mechanism?

Does it support 7×24h operation and fault-tolerance mechanism? Does the

If the single machine is abnormal, can it realize automatic switching to the backup system?

Does the system have automatic shutdown protection in case of power failure/overpressure and other emergencies?

Universality and Maintenance Convenience

Are equipment parts standardized? Can spare parts be obtained quickly?

Does the system support local + remote dual-mode diagnosis?

Does it have modularized design to facilitate local maintenance without affecting the overall situation?

Brand After-sales and Remote Service Capability

Is there a global technical service network? Is there an English/multilingual after-sales team?

Does it support efficient delivery modes such as video guidance, VPN remote tuning and online training?

Suggestion: Prioritize brands with “fast response + global maintenance support” to ensure that system problems can be solved without relying on local engineers.

5. Intelligent Control and Integration

The control and data uploading ability of oxygen system determines the operation and maintenance efficiency of the whole system, fault early warning response, and cross-system synergy. Especially in modern hospitals and smart factories, the requirements for equipment “visualization + remote” are getting higher and higher.

Control mode and interface friendliness

PLC logic control: does it support multi-time/load control, automatic cleaning/back-purging?

Touch screen HMI: Does it support Chinese/English interface, does it have authority management, log review?

Is it possible to set parameter lock to prevent misoperation?

Communication protocol compatibility

Does it support SCADA, 485, Modbus, 4~20mA?

Does it support TCP/IP access for subsequent docking to cloud platform/intelligent terminal?

Does it support historical data export + real-time alarm upload?

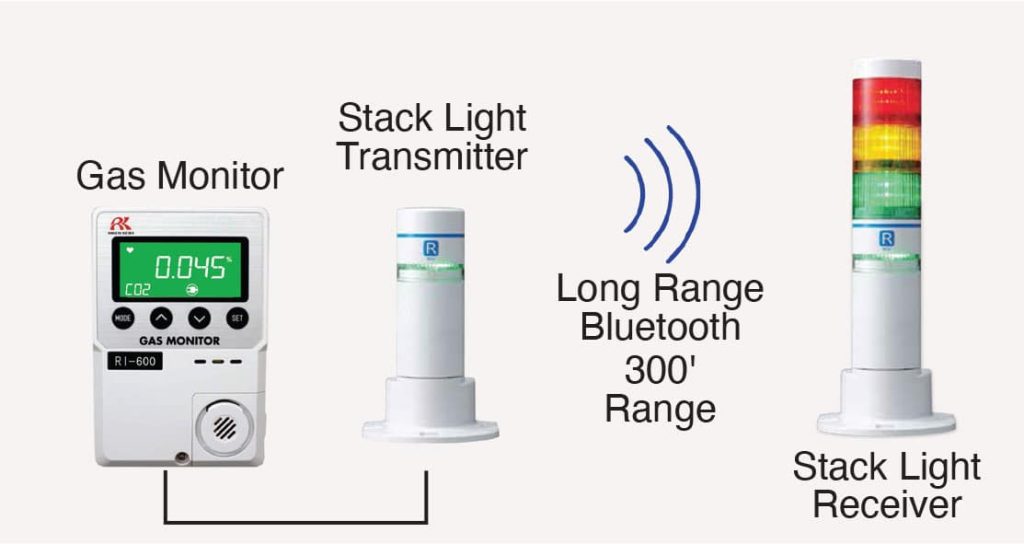

Multi-dimensional remote monitoring capability

Real-time monitoring and uploading: oxygen concentration, pressure, temperature, humidity, current, voltage, etc.

Does it support WeChat/email alarm?

Does it have remote fault localization and one-key repair function?

Does it support automatic compensation for oxygen concentration fluctuation and “day and night time operation strategy”?

Medical/Industrial System Synergy

Medical System: Does it support HIS (Hospital Information System)?

Industrial system: Is it compatible with production management platforms such as MES/ERP?

Recommended Configurations by Scenario

Application Scenarios | Recommended Technologies | Flow rate range | Remarks |

| ICU/Operating Room | PSA Medical | 10~100 L/min | Recommended double tower structure + purity alarm |

| Industrial Welding | PSA Industrial | 50~500 Nm³/h | Equipped buffer tank + flow meter |

| Ozone Response | VPSA Systems | ≥1000 Nm³/h | Recommended ≥95% purity system |

| Highland Hospital | VPSA Customized | 30~300 Nm³/h | Optional plateau compressor + remote monitoring |

| Emergency Vehicle Loading | All-in-One Mobiles | 5~30 Nm³/h | Optional with UPS or diesel power generation |

6. Brand and Supplier Selection

When purchasing oxygen equipment, the brand’s technological accumulation and the supplier’s delivery capability are the core factors determining the system’s long-term operational reliability, after-sales protection and return on investment. The following are the recommended dimensions to focus on when selecting:

Does it have key certification qualifications?

Certification is not only the embodiment of compliance, but also an endorsement of quality and safety, especially important in the international export, medical/food/environmental protection industry:

CE (EU mark of conformity): applicable to the EU market, is the threshold of entry;

ISO13485: quality system certification of medical devices, mandatory for hospitals and specialized equipment;

ASME: U.S. Pressure Vessel Certification for export to North America and the specialty gas industry;

PED: EU Pressure Equipment Directive certification, an important standard for industrial oxygen stations to enter the European Union.

Suggestion: Priority is given to brands that have passed many international certifications to facilitate global application/export.

Does it support non-standard customization and engineering landing?

Different users (hospitals, glass factories, water plants, etc.) have different requirements on gas volume, purity, control interfaces, etc., so manufacturers’ engineering customization capability is crucial.

Key assessment:

whether to support the customization of working condition simulation, system selection programming, P & ID flow chart output;

whether there are typical successful cases, such as the Middle East high-temperature conditions, power outages in Africa, mountainous plateau hospitals, etc.;

whether to support the delivery of the project period in phases according to the project duration, remote intermodulation, and local installation guidance.

Suggestion: When communicating with the factory, request to see more than 3 on-the-ground project programs/commissioning reports.

Factory delivery capability and volume production capacity

An excellent industrial equipment supplier should have strong “scale + standardization + rapid delivery” capability to avoid order delivery delays or unstable delivery.

The inspection dimensions include:

whether it has a standardized product line (e.g. 10Nm³/h~3000Nm³/h multiple specifications in stock);

whether it has modularized design capability, such as tower/rack/pipe integration;

whether it can deliver ≥30 sets of systems per month;

whether it supports rapid replacement, after-sales response, and localization of spare parts warehouse.

Suggestion: When visiting the factory, pay attention to whether there are equipment assembly test platform, material inventory area, aging area and packaging factory process.

Recommended brands brief review reference:

| Brands | Certifications | Application Areas | Whether to support customization |

| MINNUO (China) | CE, ISO13485, PED | Industrial/Medical Dual Line | Strong customization capability, rich overseas projects |

| AirSep (USA) | CE, ASME | Large-scale industrial and mining, pharmaceutical plants | High degree of modularity |

| Oxymat (Denmark) Brands | CE, PED | Military, marine, deep-sea projects | Adaptable to extreme environments and high-pressure scenarios |

Conclusion

Oxygen equipment selection is not just about choosing a piece of equipment, but also a strategic decision with comprehensive consideration of “usage scenario × parameter matching × cost evaluation × system integration × after-sales service”. Different types of oxygen systems (e.g. PSA, VPSA, liquid oxygen, portable) correspond to different needs in different places – hospital ICU emphasizes purity and stability, industrial glass/smelting focuses on flow rate and continuous operation ability, while highland or mobile places pay more attention to the equipment’s environmental adaptability and intelligent control.

Reasonable selection strategy should be “applicability + cost-effective + operation and maintenance efficiency” as the core, rather than blindly pursuing high parameter configuration. Priority should be given to manufacturers with customization capability, remote monitoring support, industry certification, service network and successful cases.

MINNUO, as a professional oxygen equipment manufacturer and system integrator, provides a wide range of solutions from 10L/min to 3000Nm³/h, covering medical, industrial and special environment applications, with CE, ISO13485, PED and other qualifications, supporting PLC/SCADA control system integration, and widely serves in Southeast Asia, the Middle East and Africa, and is highly praised by customers. We have been well received by our customers.

sales2:+86 17506119168

sales2:+86 17506119168