In today’s oxygen-dependent industries—whether medical, industrial, or remote infrastructure—uninterrupted gas supply is not just desirable, it’s critical. Yet many operators underestimate the impact of irregular maintenance on PSA (Pressure Swing Adsorption) oxygen generators. Over time, small issues like clogged filters or sensor drift can silently degrade oxygen purity, trigger false alarms, or even force costly shutdowns. The consequences aren’t just technical—they’re financial and operational.

While PSA systems are designed to be efficient and low-maintenance, that doesn’t mean they’re maintenance-free. Even the best machines rely on clean air, responsive sensors, and healthy adsorption media to function properly. Maintenance isn’t about fixing what’s broken—it’s about preventing failure before it starts. That’s why establishing a structured, environment-aware service plan is essential for long-term success.

This article aims to give operators, technicians, and procurement managers a practical, step-by-step roadmap for maintaining their PSA oxygen generators. From understanding which components wear out fastest, to knowing when to replace molecular sieves or recalibrate sensors, we’ll walk you through what to monitor, how often, and what proactive habits will maximize uptime, minimize repair costs, and protect your oxygen supply—wherever you operate.

1. Understanding Key Components That Require Servicing

A PSA oxygen generator is a complex system with multiple interdependent subsystems. Understanding what each part does—and why regular servicing is critical—can significantly improve operational stability, oxygen purity, and system longevity.

1.1 Air Compressor – The Motor-Driven Heart of the System

Function: Supplies compressed air, which is the raw input for oxygen separation

Why It Matters: If the compressor is underperforming (due to overheating, oil saturation, or dirty filters), the entire system suffers.

Service Needs:

Oil change (if oil-based): every 2,000–3,000 hours

Intake filter replacement

Check for abnormal noise or vibrations

1.2 Pre-Treatment Unit (Filters + Air Dryer) – First Line of Defense

Function: Removes moisture, dust, and oil vapors from the intake air

Why It Matters: Clean air is vital for protecting the molecular sieves. Moisture or oil can permanently damage them.

Service Needs:

Replace pre-filters every 2,000–3,000 hours

Check differential pressure indicators

Regenerate or replace desiccant cartridges in the dryer

Test auto-drain valve for condensate removal

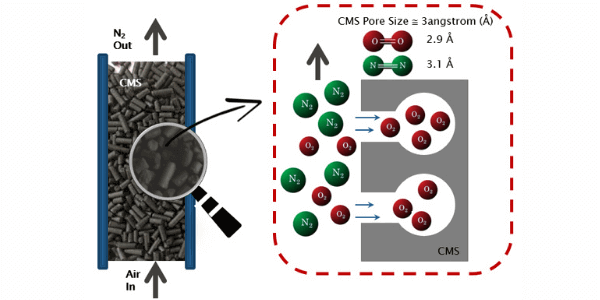

1.3 PSA Towers & Molecular Sieve Beds – The Core Separation Unit

Function: Nitrogen is adsorbed by the molecular sieve, while oxygen passes through

Why It Matters: Worn or saturated sieves reduce oxygen purity and increase energy use

Service Needs:

Replace sieve beds every 8,000–12,000 hours depending on air quality

Monitor tower switching times

Check for pressure spikes or purity drift

1.4 Buffer Tanks – Smooth Out Pressure Fluctuations

Function: Stores oxygen temporarily, stabilizing output flow and absorbing short-term demand spikes

Why It Matters: Moisture buildup in tanks can cause corrosion and affect downstream purity

Service Needs:

Manually drain moisture daily (unless equipped with automatic drain)

Inspect safety relief valves

Clean interior annually if located in humid environments

1.5 Sensors & PLC Control Panel – Brain of the Operation

Function: Monitors oxygen purity, pressure, flow rate; handles tower switching and alarms

Why It Matters: Inaccurate sensors can trigger false alarms or lead to mismanagement of the system

Service Needs:

Recalibrate sensors every 6–12 months

Check PLC software logs and backup regularly

Clean electrical terminals and test HMI touch responsiveness

2. Recommended Maintenance Schedule at a Glance

Preventive maintenance ensures that your PSA oxygen generator delivers consistent oxygen purity, runs efficiently, and avoids costly unplanned downtime. The following table outlines the recommended tasks, service intervals, and why each is critical.

PSA System Maintenance Checklist

| Task | Suggested Frequency | Why It Matters / Notes |

| Check oxygen purity & pressure | Daily | Ensures the system delivers medical/industrial-grade oxygen; use onboard or handheld analyzer |

| Drain buffer tank moisture | Daily/Weekly | Prevents corrosion and contamination; frequency depends on ambient humidity and auto-drain function |

| Replace pre-filters (dust/oil) | Every 2,000–3,000 hours | Protects sieve beds from contaminants; monitor pressure drop across filter housing |

| Replace coalescing filter | Every 4,000–6,000 hours | Prevents oil vapor from reaching the PSA tower, which can permanently degrade sieve performance |

| Air compressor oil change | Every 2,000–3,000 hours (oil-based models) | Prevents wear and overheating; use manufacturer-specified lubricants only |

| Compressor intake filter | Every 3 months (or sooner) | Dirty intake = hot compressor + poor air quality; clean more frequently in dusty sites |

| Replace molecular sieve | Every 8,000–12,000 hours | Adsorption capacity diminishes over time; early replacement improves efficiency and purity recovery |

| Recalibrate sensors | Every 6–12 months | Maintains measurement accuracy for purity, pressure, flow rate; essential for PLC-controlled systems |

| Full system inspection | Annually | Identify aging hoses, leaking valves, PLC log errors; ideal before seasonal load increase |

Operational Tips & Real-World Best Practices

Avoid reactive maintenance: Delaying replacement of filters or sensors may cause cascading failures—e.g., saturated filters lead to contaminated sieves.

Keep a logbook: Record run-hours, maintenance events, error codes. Use Excel, cloud logs, or manufacturer-provided maintenance software.

Use genuine parts: Non-OEM filters or oils can lead to hidden risks (wrong flow resistance, thermal breakdown, non-compliant materials).

Schedule service during off-peak times: Prevent interruptions during high oxygen demand (e.g. during medical flu season or industrial shifts).

Train operators to recognize early signs: Noise changes, slow tower switching, drops in purity, or increased compressor temperature are red flags.

3.Signs You Should Service Sooner Than Scheduled

Even with the best maintenance schedules in place, real-world conditions such as environmental factors, usage intensity, and component fatigue may cause certain failures before the expected service window. Recognizing these early warning signs is key to avoiding larger system failures, oxygen quality issues, or even safety incidents.

3.1 Drop in Oxygen Purity (<90%)

What it suggests: Saturated molecular sieves, dirty filters, valve malfunction

What to do:

Confirm purity via a calibrated handheld analyzer

Check dryer function and pre-filter status

Consider early sieve replacement if other variables are normal

Tip: A sudden drop may indicate moisture breakthrough—check dew point sensor logs if available.

3.2 Frequent Alarms or Auto-Shutdowns

What it suggests: Electrical instability, pressure faults, sensor drift

What to do:

Check PLC event logs for recurring fault codes

Recalibrate sensors and check valve switching logic

Inspect power input voltage for fluctuation

Real-world cause: Loose wiring or corroded sensor terminals are common but often overlooked.

3.3 Excessive Moisture or Oil in Outlet

What it suggests: Failure in air dryer, coalescing filter, or compressor separator

What to do:

Manually inspect condensate from tank and filters

Replace coalescing filters

If using oil-lubricated compressor, check for separator failure

Risk: Moisture and oil can permanently damage sieve material, causing cumulative purity loss.

3.4 Compressor Overheating or Noise

What it suggests: Blocked airflow, poor ventilation, wrong oil type or quantity

What to do:

Ensure ≥1m clearance around compressor

Replace intake filter

Use OEM-specified oil, refill to mid-sight-glass level

Symptom to watch: Housing hot to the touch after <20 min run time = thermal stress indicator.

3.5 Valve Switching Noise Delay or Irregularity

What it suggests: Solenoid fatigue, debris in valve seats, PLC timing offset

What to do:

Listen for “click” timing delays between tower switches

Manually test valve response via control panel

Clean valve internals or replace coil if non-responsive

Impact: Delayed switching leads to poor adsorption cycle performance and oxygen fluctuation.

✅ Actionable Summary:

| Symptom | Possible Fault | Recommended First Check |

| Low purity | Sieve beds or filter saturation | Test purity + inspect pre-treatment |

| Moisture in outlet | Dryer or drain failure | Check auto-drain, replace desiccant |

| Loud compressor | Intake blockage or oil problem | Clean filter + confirm oil grade |

| Alarms persist | Sensor drift or wiring issue | Recalibrate + check electricals |

| Switching delays | Valve wear or logic fault | Test solenoid function manually |

4.The Molecular Sieve: When and Why to Replace

The molecular sieve is the critical component that enables a PSA (Pressure Swing Adsorption) oxygen system to do its job. It’s the “invisible worker” that separates nitrogen from air, allowing concentrated oxygen to flow into your pipeline. But like any consumable, it doesn’t last forever.

Role: Selective Adsorption of Nitrogen

The sieve is typically made of zeolite, a microporous material that selectively captures nitrogen molecules while allowing oxygen to pass through.

It works under a cyclical pressurization-depressurization process, switching between two towers every 45–60 seconds.

⏳ Lifespan: 8,000–12,000 Hours

(Assumes dry, clean air and proper pre-treatment)

Poor air quality can reduce lifespan to 5,000–7,000 hours

Humidity or oil contamination can irreversibly damage the adsorption efficiency

High ambient temperatures (>40°C) may accelerate degradation

Signs of Saturation or Decline

| Symptom | Underlying Issue | Implication |

| Tower switching becomes slow or uneven | Sieve internal resistance increases | Tower cycle mismatch → unstable output |

| Oxygen purity drops <90% | Adsorption sites are full or fouled | Risk of production shutdown or product rejection |

| Energy use increases | Compressor compensates for lower purity | Higher operating cost per Nm³ of O₂ |

If oxygen purity continues to drop even after filter replacement and air quality checks, the sieve is likely the cause.

Can You Regenerate It?

Some systems support hot air or vacuum regeneration, but this is limited to industrial PSA plants or specific high-capacity towers.

In most commercial/medical PSA systems:

Sieve regeneration is either not supported or uneconomical due to labor, tools, and downtime

Complete replacement is faster, safer, and ensures restored performance

MINNUO tip: Always record cumulative run-hours and track performance degradation curves. We provide pre-packed sieve kits that match your tower volume for rapid, tool-free replacement.

Best Practice: Replacement Strategy

Replace sieves preventively before total saturation, not after purity collapse

Use genuine or certified sieves to ensure pore size compatibility and packing density

During replacement:

Clean tower internals, inspect valve seats, check for desiccant dust

Reseal using correct torque and leak-test after assembly

5.How to Plan for Spare Parts and Downtime

Even the best-built PSA oxygen generator can face unexpected issues—what separates successful operators from costly downtime is preparation. Effective spare parts planning reduces system interruptions and enhances service predictability.

✅ Key Planning Tactics

5.1 Keep a Digital Maintenance Log

Record total run-hours, maintenance intervals, error codes, part replacements

Use Excel, cloud-based CMMS (Computerized Maintenance Management System), or dedicated manufacturer apps

Helps anticipate next service dates and verify warranty claims

5.2 Stock Critical Consumables On-Site

| Part | Recommended Quantity | Why Keep in Stock |

| Dust & coalescing filters | 2–3 sets | Fast-clogging in humid/dusty conditions |

| Solenoid valve kits | 1 per tower | Failures may lead to tower imbalance |

| Oxygen sensor | 1–2 spares | Sensor drift is hard to detect until output fails |

| Lubricants/seal rings | 1 year supply | Avoid delay from non-standard shipping restrictions |

5.3 Use Predictive Maintenance Tools

Dew Point Sensor: Alerts if dryer/moisture separator underperforms

Flow Rate Monitor: Detects gradual degradation of output capacity

Smart Alarms with Logging: Enables time-based fault analysis

5.4 Secure Regional Service & Inventory Support

Partner with suppliers like MINNUO, who provide:

ASEAN & Middle East warehousing

Pre-packed component kits

48-hour emergency dispatch

Remote diagnostics & video-assisted support

Pro Tip: If your oxygen generator supports PLC-based diagnostics, set up pre-alarms to notify you of abnormal conditions (e.g. filter pressure drop >10%, temperature rise, delayed valve response).

6.Tips to Extend PSA Generator Lifespan

Your PSA generator is an investment designed to operate for 8–10 years or longer—but only if operated under the right conditions. These best practices can extend system lifespan, reduce service calls, and save thousands in repair costs.

Practical Tips

6.1 Ensure Proper Ventilation

Maintain ≥1 meter clearance on all sides of the compressor and control cabinet

Install exhaust fans if ambient temperature >35°C

Heat buildup is a leading cause of control panel and compressor damage

6.2 Install Upstream Air Quality Monitor

Constantly monitors intake air quality before filtration

Detects abnormal humidity/oil intrusion early

Enables better diagnosis when purity drops

6.3 Avoid System Overload

Stay within the rated flow (e.g. 10 Nm³/h system should not exceed 11–12 Nm³/h for long durations)

Overloading leads to:

Faster sieve saturation

Pressure drop and purity loss

Reduced tower life

6.4 Never Bypass Maintenance Alarms

Alarm override may seem convenient short-term

Risks include: compressor overheating, dryer failure, purity loss without warning

Always investigate the root cause

6.5 Train Operators on Early Warning Signs

| Symptom | Likely Root Cause |

| Tower doesn’t switch on time | Valve wear or moisture ingress |

| Compressor unusually loud | Dirty intake or wrong oil |

| Output pressure unstable | Clogged filters or sensor drift |

| Purity slowly declining | Early sieve saturation or leakage |

Conclusion: Service is Not a Cost—It’s an Investment

Maintaining a PSA oxygen generator isn’t just a matter of compliance—it’s a proactive strategy that directly impacts the purity, reliability, and longevity of your oxygen supply. Every timely filter change, sensor recalibration, or molecular sieve replacement contributes to reduced energy costs, extended component life, and more predictable operations. Preventive service isn’t just about fixing problems—it’s about avoiding them altogether.

Smart operators view maintenance as an asset—not an inconvenience. With consistent care, your system is less likely to experience sudden shutdowns, oxygen purity drops, or compressor failure. Whether you operate in hospitals, high-altitude environments, or demanding industrial plants, tailoring your maintenance plan to your environment and workload is key. Log your maintenance history, monitor early warning signs like valve delays or outlet moisture, and act before minor issues escalate into costly downtime.

At MINNUO, we believe real reliability begins after the sale. That’s why we provide more than equipment—we deliver complete lifecycle support. From pre-packaged spare parts kits and regional warehousing (ASEAN, Middle East, Africa) to remote diagnostics, maintenance forecasting tools, and expert consultations, we help our partners maintain continuity with confidence.

sales2:+86 17506119168

sales2:+86 17506119168