In 2025, liquid nitrogen is becoming a fundamental resource for a number of industries around the world, with demand continuing to grow in everything from food quick-freezing and biomedical to industrial manufacturing. However, many countries are facing high prices. In Brazil in particular, the price of liquid nitrogen is not only chronically high, but also fluctuates frequently, which has put significant pressure on production planning, cost control and market expansion. Through this phenomenon, we must return to the essence: what makes liquid nitrogen become a “luxury” in Brazil?

From logistics and transportation to tax and fee structures, the supply chain for local liquid nitrogen in Brazil has always had systemic barriers that are difficult to ignore. First, the large transportation radius and high evaporation rate of liquid nitrogen lead to loss and uncertainty in every delivery; second, the limited number of centralized production sites makes the market monopolized in some areas, with a lack of effective price competition; and third, the high import tariffs and multiple sales taxes together push up the end-use costs. All this forms a vicious circle: enterprises that can afford to use the product passively endure the high price, while small and micro enterprises that are just starting out are kept out of the door.

So the question is – with demand for liquid nitrogen rising, is there a way for Brazilian companies to break out of their high price dependency? Could “in-house production” be the game-changer? Read on to find out why more and more Brazilian companies are choosing to invest in their own liquid nitrogen generation systems and get ahead of a real cost reduction revolution.

1. Is It Worth Buying a Liquid Nitrogen Generator in Brazil?

As the demand for industrial gas continues to rise, a steady supply of liquid nitrogen has become a critical part of business operations in industries such as healthcare, food cold chain, animal husbandry and research. In Brazil, relying on externally sourced liquid nitrogen faces a number of challenges, such as price fluctuations, transportation challenges, and supply disruptions. So, is it worth investing in a liquid nitrogen production system of your own? Here’s an in-depth look at the cost, payback period and long-term strategic value.

Cost Comparison: Local Sourcing vs. Build Your Own System

For companies with an annual demand of 5 tons or more, a self-built liquid nitrogen system usually breaks even in 3-5 years. Below is a basic comparison model (using the price of R$1,500 per ton as a reference):

| Cost Components | Purchased liquid nitrogen (annual) | Self-built system (annual) |

| Unit Prices | R$1,500 / ton | R$500-700 / ton |

| Annual Demand 10 tons | R$15,000 | R$5,000-7,000 |

| Freight & Loss | R$2,000-3,000 | 0 (locally produced gas) |

| Risk of Uncontrollable Price Increase | high | Low |

| Total Annual Expenditures | R$17,000-18,000 | R$5,000-7,000 |

Conclusion: Once the annual demand exceeds 5 tons, a self-built system will significantly reduce long-term gas usage costs, especially in factory or farm scenarios away from cities.

Payback Cycle and Revenue Modeling: 3, 5, 10 year budgeting

Taking the MINNUO liquid nitrogen machine as an example, assuming a purchase price of about R$80,000, operating power of 5kW, producing 20L of liquid nitrogen 24 hours a day, 300 days a year, and an electricity price of R$0.7/kWh:

3 year model: about 6 tons of gas per year, with a cumulative savings of more than R$30,000. After taking into account the cost of maintenance, labor, and electricity, the initial investment can be recovered in 3 years.

5 year model: Over 100% return on investment, generating a sustainable surplus.

10 year model: Save R$80,000 – R$100,000 or more compared to continuous off-take, resulting in a return of capital and accumulation of profits.

The added value of stable gas supply: more than you think

In addition to direct cost savings, a liquid nitrogen self-supply system can bring the following value-added benefits:

Uninterrupted production guarantee: Especially suitable for scenarios where a break in the cold chain would result in high losses, such as frozen sperm preservation, biological samples preservation and so on.

Avoidance of transportation risks: Rainy seasons, strikes, and logistical disruptions can lead to external supply failures, a pain point that self-supply systems avoid.

Enhance bargaining power and customer trust: We can expand our business externally as a “liquid nitrogen service center”, and internally, we can improve quality control and response efficiency.

Environmental protection and branding effect: The self-built system supports energy-saving operation and timed start/stop, which helps enterprises to comply with ESG.

✅ Portrait of suitable people and judgment criteria

Is it suitable to invest in self-built liquid nitrogen machine? You can quickly judge according to the following criteria:

| Conditions | Level of Recommendation |

| Annual demand for liquid nitrogen ≥ 5 tons | ✅ Highly Recommended |

| Remote location of the enterprise, inconvenient transportation | ✅ Recommended |

| Products require high stability of gas supply | ✅ Recommended |

| Medium and long-term stable orders or production lines | ✅ Recommended |

| Annual demand <2 tons, and close to the liquid nitrogen supply station | ❌ Temporarily Not Recommended |

2. How to Choose the Right Liquid Nitrogen Generator for Your Needs

Before choosing a liquid nitrogen generator, enterprises must make scientific judgments based on their business continuity needs, nitrogen cost control, site layout limitations, maintenance convenience and other multiple practical conditions, rather than focusing only on the equipment offer.

Clarify the application scenario: output determines the model

There are significant differences in the industries and ways of using the models with different liquid nitrogen outputs:

Low output type (5~20L/h): suitable for laboratories, small pharmaceutical enterprises or university research projects, focusing on the small footprint and immediate production;

Medium output type (20~100L/h): suitable for continuous medium nitrogen demand scenarios, such as the food cold chain, cooling of electronic devices;

High output type (100L/h or more): suitable for continuous medium nitrogen demand scenarios; High output type ( High production type (more than 100L/h): matching the demand for large volume use such as metal heat treatment, large medical institutions, milk factories, cold testing of aerospace materials, and so on.

MINNUO offers customizable options for production levels and redundant configurations for future expansion possibilities, ensuring that the investment is not too big too soon and not too short.

⚙ Technical indicators are more than “flow” – analysis of key parameters

Selection can not only look at the flow rate, but more critical is the balance of the following four core parameters:

Nitrogen purity: the standard industrial nitrogen is generally 99.5%, some of the precision cooling field up to 99.999%. Cooling field can reach 99.999%, affecting the use of safety and cooling effect;

Power consumption ratio (kWh/Nm³): a measure of the unit of nitrogen production energy consumption, is an important basis for evaluating the operating costs;

Recovery rate and heat emission: to determine the need for supporting cooling towers or heat recovery devices;

Refrigeration Efficiency: whether to adopt the use of liquid nitrogen pre-cooling, closed-loop structure of the cold head, and whether to support the energy-saving control of the frequency, etc., are all related to the overall operating costs.

MINNUO introduces intelligent modular design, and the core system adopts high-efficiency compressor refrigeration unit, which ensures stable operation in tropical countries such as Brazil and reduces the fluctuation problem caused by environmental temperature difference.

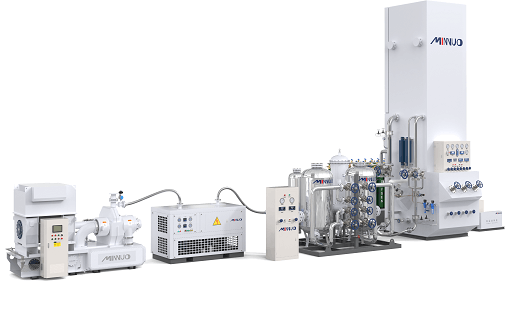

MINNUO’s matching and integration capability: not a single unit, but an integrated system solution.

The true meaning of “matching” is not only matching the performance of the mainframe, but also the synergistic integration of the upstream and downstream systems:

Optional tanks: vertical/horizontal liquid nitrogen tanks, with a capacity ranging from 200L to 10m³, to satisfy different cycles of nitrogen storage;

Pressurization and delivery system: optional secondary gas supply module with safety valve and vacuum adiabatic pipeline, suitable for long-distance delivery;

PLC remote monitoring system: with cloud-based remote management interface, visualization of operating parameters and fault warning;

Environmental adaptability design: customized reinforcement system is provided for plateau areas, hot and humid atmosphere to ensure safe operation of the equipment in a variety of extreme conditions.

✅ Case tip: After purchasing a MINNUO liquid nitrogen machine, a dairy processing plant in South America saved nearly 18% of nitrogen purchasing cost on average per day and increased production efficiency by 12% through the customized pressurization system and 7×24 hours monitoring platform.

3. From Buyer to Supplier: How Owning a Generator Unlocks New Income

As the price of nitrogen and oxygen equipment decreases and the demand for localized services grows, more and more customers are moving away from being just end-users to becoming regional supply centers. This shift not only improves the return on equipment investment, but also opens up new windows of profitability for customers.

✅ The case of a regionalization center: transformation from user to provider

In southern Brazil, a user initially used a MINNUO liquid nitrogen machine for the daily frozen medical needs of its own clinic after purchasing the machine. With surplus capacity, the customer gradually expanded its service radius to become a regional refrigerant gas supply point for five neighboring farms, two veterinary clinics and a laboratory. This case shows that mastering core equipment not only reduces internal costs, but also realizes revenue diversification through “external supply”.

✅ Reconstruction of Profit Model: Secondary Gaining Space of Small Liquid Nitrogen Station

After meeting the demand for self-use, customers can realize secondary profitability through the following paths:

Bottle Supply: Using the existing liquid nitrogen storage tank equipment, the product is divided into small bottles and sold to the neighboring clinics or university laboratories;

On-demand filling service: provide “door-to-door nitrogen filling” service to neighboring customers through a simple reservation system to establish stable customer stickiness;

Establishment of cooperation nodes: sign long-term gas supply agreements with local veterinary clinics and breeding farms to form a service network.

✅ Grasp the policy dividend: Import substitution and localization incentives

The Brazilian government has continued to promote local manufacturing in recent years, encouraging less reliance on imported medical and industrial gases. Customers who purchase and operate local nitrogen generation equipment are eligible for partial tax breaks and subsidies from the Local Manufacturing Development Fund. For those who want to transform into “regional gas suppliers”, this is both a window of policy dividends and the best time to enter the local market.

✅ MINNUO customized support: not only equipment, but also system solutions

We not only provide high-performance liquid nitrogen equipment, but also provide complete regional service model design according to customers’ needs, including:

Intelligent supporting tanks and remote monitoring system

Charging and service module SaaS software interface

Safety fittings for dispensing and special transportation containers

Through the combined delivery of “equipment+scenario+system”, we can help customers to develop and develop their business in the local market.

4. Why MINNUO’s Liquid Nitrogen Generators Are Built for Brazil

In Brazil, the realities of high temperatures and humidity, the high cost of electricity, and the large transportation radius are reshaping the logic of purchasing liquid nitrogen equipment. MINNUO is not simply an exporter, but a customized solution for the South American scenario.

Heat-resistant – corrosion-resistant – highly adaptable

All-weather operation design: heat-resistant up to 45°C, built-in cooling system not afraid of the tropical climate

Corrosion-resistant material process: the whole machine adopts marine-grade spraying, adapting to the coastal salt spray environment

Modular structure: easy to be deployed at fragmented sites in the tropics, and more flexible in installation

⚡ Energy-saving – Intelligent – easy to be operated

Auto-start/stop system: automatic start when nitrogen is used, and no one is in attendance High efficiency

Intelligent Power Saving Mode: Designed to optimize the night time program for the peak electricity price in Brazil

Multi-language Control Interface: Built-in Portuguese UI and remote operation and maintenance tutorials reduce the technical threshold

After-sales Guarantee – No Fear of Remoteness

6-Hour Remote Response: MINNUO South America support points cover the core area

One-click Failure Report: Built-in diagnostic system generates the service request automatically

Spare Parts Warehouse Support: Generalized design of the key modules allows users to independently replace the core components Replacement of core components by users

User data drives product evolution

Every device used in Brazil is connected to MINNUO’s cloud-based operation record system, which continuously collects feedback and performance data to promote the optimization of firmware, parameters, and structure, so as to achieve the goal of “once used, once improved”.

Conclusion: When buying a liquid nitrogen machine in Brazil, choosing the right brand is far better than choosing the right product that “understands you”; MINNUO is not just a manufacturer, but also a solution provider with a deep commitment to South America.

Conclusion

In a context of global energy price volatility and supply chain uncertainty, in-house production of liquid nitrogen is no longer the sole preserve of the large corporations. 2025 is the year when the Brazilian market would be wise to “move from dependence to control” of the cost of liquid nitrogen.

Even small and medium-sized enterprises (SMEs) can realize long-term benefits from a one-time investment, avoiding the risks of high transportation costs and sudden supply cuts. This is not only a way to reduce operating costs, but also a key step in controlling the lifeblood of your business.

MINNUO offers customized liquid nitrogen solutions for the high temperatures, high humidity and fluctuating electricity prices of South America, helping more local customers to realize a clear path to “return on investment”. Start calculating your payback now, and let liquid nitrogen become the backbone of your stable development from now on.

sales2:+86 17506119168

sales2:+86 17506119168