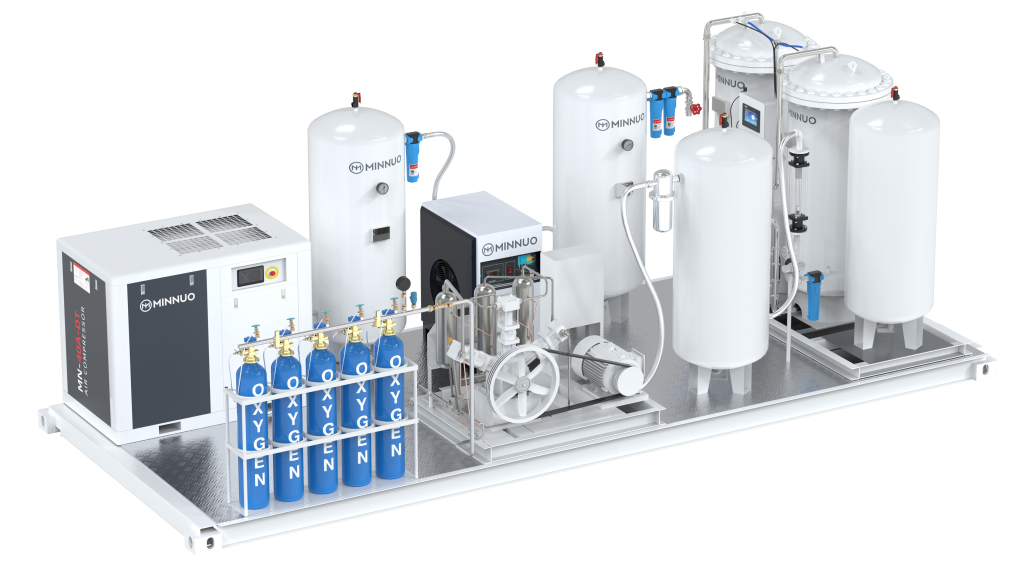

In modern fish farming, maintaining optimal dissolved oxygen is critical. An onsite aquaculture oxygen generator offers a reliable and cost-effective solution compared to traditional methods. By implementing a dedicated oxygen system for fish farming, operators can ensure 24/7 oxygen supply, significantly improving survival rates. Minnuo provides advanced oxygen plants for aquaculture designed to meet the rigorous demands of high-density fish production.

Oxygen plays a critical role in maintaining the health and productivity of aquatic life. In aquaculture, a consistent and reliable oxygen supply is essential for promoting fish growth, reducing mortality, and ensuring optimal water quality. This article examines how oxygen affects aquaculture operations and the value of efficient oxygen systems.

To maintain healthy aquatic environments, oxygen helps support vital biological processes such as respiration and waste breakdown. However, fish farms often struggle with fluctuating oxygen availability, making it important to implement systems that guarantee a steady and high-quality oxygen supply. This is where PSA (Pressure Swing Adsorption) oxygen generators can offer a reliable solution.

By integrating PSA oxygen generators into their operations, aquaculture farms can ensure a steady oxygen supply, reduce reliance on external suppliers, and lower operational costs. In the following sections, we’ll explore the benefits of PSA systems and how they can improve aquaculture efficiency, ensuring long-term sustainability.

Why Your Facility Needs an On-site Oxygen Plant for Fish Farming

In the competitive world of aquaculture, reliability is the foundation of success. Relying on external oxygen deliveries—such as liquid oxygen (LOX) tanks or cylinders—exposes your business to significant risks. Logistics delays, weather conditions, or supply chain disruptions can lead to a catastrophic drop in dissolved oxygen levels, potentially resulting in the loss of your entire fish stock within hours.

Installing an on-site oxygen plant for fish farming eliminates these variables. By generating your own high-purity oxygen directly from the air, you gain:

- Total Autonomy: No more waiting for delivery trucks; your supply is as constant as your electricity.

- Risk Mitigation: Ensure a 24/7 oxygen supply even in remote locations, protecting your investment from sudden market shortages.

- Cost Stability: Hedge against the rising costs of industrial gas and transportation surcharges.

Tailored Oxygen Solutions for Different Growth Stages

Not all fish have the same metabolic requirements. Oxygen demand fluctuates significantly based on life stage, water temperature, and biomass density. A “one-size-fits-all” approach often leads to either dangerous oxygen dips or wasteful over-saturation. Our onsite aquaculture oxygen generators provide the flexibility to adjust output based on the specific needs of your facility.

Oxygen Generator for Hatcheries & Broodstock

The earliest stages of fish life are the most critical. Hatcheries and broodstock tanks require the highest precision in oxygen levels to ensure optimal embryonic development and larval survival. Even minor fluctuations can lead to deformities or high mortality rates in fry.

Our PSA oxygen systems provide a stable, high-purity flow of oxygen that can be finely tuned to:

- Enhance Reproductive Success: Stable DO levels reduce stress in broodstock, leading to higher quality eggs and sperm.

- Accelerate Fry Growth: Consistent oxygenation promotes faster metabolism and better feed conversion ratios (FCR) in the nursery.

- Maximize Long-term Output: Healthy fingerlings are more resilient to disease when moved to grow-out pens, securing your farm’s future yield.

Dedicated Oxygen Generator for Salmon Farming

Salmon are particularly sensitive to oxygen fluctuations and environmental stressors. Whether in sea cages or land-based Recirculating Aquaculture Systems (RAS), maintaining high oxygen saturation is non-negotiable for Atlantic or Pacific salmon.

Our onsite systems are engineered to handle the high-volume demands of salmon farming. By integrating our oxygen system for fish farming into your RAS or cage aeration setup, you can maintain optimal dissolved oxygen even during peak summer temperatures or high-density feeding cycles. This precision prevents respiratory distress and ensures the firm flesh texture and rapid growth that premium salmon markets demand.

1. What Is a PSA Oxygen Generator?

Introduction to PSA Technology:

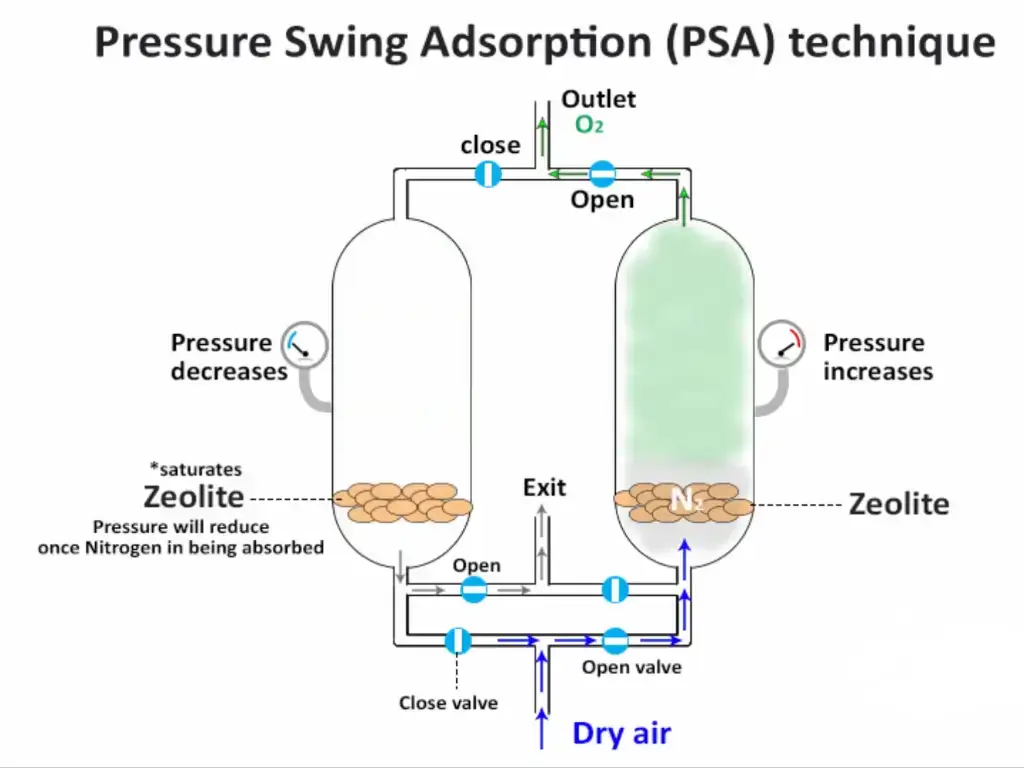

A PSA (Pressure Swing Adsorption) oxygen generator is a highly effective and reliable technology designed to produce high-purity oxygen. The PSA process works by using a special material, often a zeolite, to separate nitrogen from air. Here’s how it works:

Air Filtration & Compression: Ambient air is drawn into the system, where it undergoes filtration to remove dust, moisture, and other contaminants.

Pressure Swing Adsorption: The compressed air is then passed through adsorbent materials (e.g., zeolite), which trap nitrogen, allowing the oxygen to pass through.

Purification and Collection: The oxygen produced is separated and collected, leaving nitrogen as a byproduct, which is vented out.

This process produces oxygen with a purity typically between 90%-95%, which is ideal for a variety of applications, especially aquaculture, where oxygen is essential for healthy fish growth and maintaining the aquatic ecosystem.

How PSA Oxygen Generators Compare to Other Methods:

Compared to traditional methods like electrolysis or using liquid oxygen tanks, PSA generators provide numerous advantages:

Cost-Effective: PSA systems typically incur lower operational costs compared to the recurring expenses of liquid oxygen deliveries.

Reliable and Continuous Supply: With a PSA generator, oxygen is produced on-demand, eliminating concerns about delivery delays or external supply disruptions. This is especially important for industries like aquaculture, where oxygen is crucial for daily operations.

Energy Efficient: PSA oxygen generators are known for their low energy consumption and high output efficiency. This makes them not only a cost-effective option but also an environmentally friendly one, especially for large-scale operations.

Modular & Scalable: PSA systems are customizable and can be scaled based on the specific needs of a business. Whether it’s a small farm or a large-scale industrial operation, a PSA system can be tailored to meet specific oxygen production requirements.

2. Benefits of PSA Oxygen Generators for Aquaculture

2.1 Continuous Supply:

One of the most significant advantages of PSA (Pressure Swing Adsorption) oxygen generators is the ability to provide a continuous, on-demand supply of oxygen. In aquaculture, maintaining a steady supply of oxygen is critical for the health of aquatic life.

Reduced dependency on third-party suppliers: By investing in a PSA oxygen generator, aquaculture operations can eliminate reliance on external suppliers who may be prone to delays, price fluctuations, or logistical challenges. This continuous on-site production ensures that oxygen is available 24/7, regardless of external factors, allowing for better control over production cycles and reducing the risk of oxygen shortages.

Reliability for daily operations: Aquaculture farms, especially those with large-scale operations, need to ensure the stability of oxygen levels in the water to prevent hypoxia (low oxygen levels), which can have detrimental effects on fish health and growth. With a PSA system, operations can maintain consistent oxygen levels throughout the year, ensuring smooth and stable farm operations.

2.2 Cost-Effective:

Investing in a PSA oxygen generator offers significant financial benefits over time, especially in comparison to purchasing liquid oxygen or relying on external gas suppliers.

One-time investment for long-term savings: While the initial cost of setting up a PSA system can vary depending on the size and capacity, it’s important to note that the ongoing operating costs are much lower than purchasing liquid oxygen. The cost of liquid oxygen deliveries, especially with fluctuating prices, can be much higher in the long run, as transportation costs, storage fees, and delivery charges can quickly add up. By investing in PSA technology, aquaculture farms can achieve substantial savings by reducing or eliminating recurring delivery costs.

Lower operational costs: Once installed, the system is relatively low-maintenance, and the electricity required for running the PSA system is often less costly than the energy demands of liquid oxygen production or tank refills. Additionally, the payback period for the investment is typically shorter (usually 3-5 years), meaning that over time, PSA oxygen generators can quickly pay for themselves.

2.3 Enhanced Fish Health:

Maintaining optimal oxygen levels is crucial for the health and growth of aquatic species in fish farms, particularly in high-density farming operations.

Higher dissolved oxygen (DO) levels: By providing a constant supply of oxygen, PSA generators help maintain higher dissolved oxygen levels in the water, which is essential for fish metabolism and overall health. Studies have shown that higher DO levels can significantly improve the growth rates of fish and shellfish, allowing farms to produce higher yields and better-quality products.

Prevention of hypoxia-related issues: Low oxygen levels, or hypoxia, can result in stunted growth, increased stress, and higher mortality rates among aquatic animals. By ensuring that oxygen is consistently available, PSA oxygen generators mitigate the risks of hypoxia, improving the survival rate of farmed fish and ultimately leading to more efficient and profitable aquaculture operations.

2.4 Environmental Impact:

In addition to providing operational and financial benefits, PSA oxygen generators also contribute to sustainability efforts by reducing the environmental footprint of aquaculture farms.

Reducing reliance on gas tanks and deliveries: Traditional methods of oxygen supply, such as using tanks and regular deliveries, often involve a high level of transportation and packaging, leading to increased carbon emissions and waste. By generating oxygen on-site, PSA systems significantly reduce the environmental impact associated with transportation, packaging, and storage. This reduction in external oxygen supply reliance also helps reduce the energy consumption required for frequent deliveries.

Eco-friendly solution: PSA systems can be paired with energy-efficient equipment and energy-saving features (such as smart start/stop functions) to further minimize environmental impact. For example, by using renewable energy sources to power the PSA system, aquaculture farms can further reduce their carbon footprint, contributing to the broader goals of sustainability within the agricultural sector.

3. Key Considerations When Choosing a PSA Oxygen Generator for Aquaculture

Selecting the right PSA (Pressure Swing Adsorption) oxygen generator for your aquaculture operation is crucial for ensuring the health of aquatic life, maintaining operational efficiency, and keeping costs manageable. Here are the key factors to consider when choosing the right system for your specific needs.

3.1 Capacity Requirements:

When evaluating a PSA oxygen generator, the first critical factor to consider is the capacity, or the amount of oxygen required to meet the demands of your aquaculture system.

Matching Oxygen Output to Aquaculture Needs: The oxygen needs for fish farming vary depending on the type of aquatic life being farmed and the size of the operation. Too much capacity can be inefficient and costly, while too little can lead to oxygen deprivation, affecting fish health.

Customized Solutions: A PSA oxygen generator’s output can be tailored to fit different farm sizes and operational requirements. For instance, small shrimp farms may need only 20-30 liters of oxygen per hour, while larger fish farms could require systems with output capabilities of 100 liters per hour or more.

3.2 Purity Levels:

Oxygen purity is a critical factor in ensuring the health of aquatic life.

Correct Oxygen Purity for Aquatic Life: For fish and other aquatic organisms, oxygen must meet a purity level of 90% or higher to be effective. The purity level of the oxygen produced by a PSA generator ensures the system delivers oxygen that is safe and beneficial to aquatic life, as impure oxygen can cause harm or stress to the organisms.

Tailored Purity for Different Species: Depending on the species being farmed, the required purity may vary slightly, but 90% is typically the standard for most applications. For higher-grade applications, such as precision breeding or sensitive species, systems that provide 99% purity or more may be required.

3.3 Energy Consumption:

Energy costs are a significant factor in the total operational expenses of running an aquaculture farm.

Ensuring Low Operational Costs: PSA oxygen generators typically use electricity to operate compressors and separation units. Therefore, the energy efficiency of the system is paramount to minimize electricity costs.

Low Energy Consumption Systems: Modern PSA generators are designed to be energy-efficient, using lower amounts of power per cubic meter of oxygen produced. Look for systems that are optimized for low energy consumption while maintaining high output efficiency.

Energy Saving Features: Some PSA generators come with energy-saving features like smart start/stop functions or variable frequency drives (VFDs), which adjust the system’s operation based on actual demand, helping to reduce energy consumption during off-peak hours.

3.4 Maintenance and Serviceability:

Every mechanical system requires maintenance, and a PSA oxygen generator is no exception.

Understanding the Maintenance Needs: Routine maintenance for PSA systems includes checking and replacing filters, ensuring air compressors are working efficiently, and inspecting valves.

Expected Service Life: PSA oxygen generators are built to last, but the quality and design of the system will determine its lifespan. Systems with robust components and modular designs often have longer service lifespans and are easier to maintain.

Service Intervals and Spare Parts: Choose a generator that offers easy access to spare parts and has a clear service schedule. For operations located in remote areas, it’s essential to ensure that local service technicians can provide maintenance or repairs when needed.

Support and After-Sales Service: Opt for systems that come with solid manufacturer support, including troubleshooting, maintenance assistance, and availability of spare parts.

3.5 Solutions & Considerations:

Different PSA Models Based on Output and Purity Levels: It’s crucial to match the right PSA model based on your farm’s scale, output requirements, and species being farmed. Different models offer various ranges of output and purity, making it important to select a system that best fits your specific operational needs.

Tailored to Aquaculture Operations: MINNUO’s PSA systems are designed with aquaculture applications in mind, offering customizable options for output and purity levels. Additionally, the system can be designed to meet the needs of specific farm scales, from small commercial farms to large-scale operations.

Modular and Flexible Systems: For operations anticipating growth or fluctuations in oxygen demand, modular systems are ideal. These systems allow for easy upgrades or adjustments to meet changing requirements without the need for a full system replacement.

4. Cost Breakdown: Is a PSA Oxygen Generator a Viable Investment?

When considering whether a PSA (Pressure Swing Adsorption) oxygen generator is a viable investment for your aquaculture business, understanding the key cost factors is crucial. Here’s a breakdown of the costs involved and how these compare to traditional oxygen delivery methods, helping you assess the long-term financial benefits.

4.1 Initial Investment vs. Operating Costs

The decision to purchase a PSA oxygen generator is largely driven by the comparison between the initial investment and the ongoing operating costs. When using liquid oxygen delivery services, aquaculture operations often face high recurring costs, including transportation and storage fees. A PSA system, although requiring a higher upfront investment, offers the benefit of significantly lower long-term costs by providing an on-demand, in-house supply of oxygen.

Initial Investment: A PSA oxygen generator typically requires an upfront cost that can range from $50,000 to $300,000, depending on the system’s capacity and complexity. While the initial cost is substantial, it should be viewed as a long-term investment that eliminates recurring transportation costs for liquid oxygen.

Operating Costs: Once installed, operating a PSA oxygen generator mainly involves electricity consumption for compression and filtration, along with periodic maintenance costs. These operating costs are significantly lower than those associated with purchasing liquid oxygen. The efficiency of modern PSA systems, with energy-saving features like automated start/stop and variable frequency drives (VFDs), minimizes the electricity bill and optimizes energy use.

Cost Efficiency: Over time, purchasing a PSA oxygen generator can result in a 40-60% reduction in annual oxygen costs. This is particularly beneficial for large aquaculture operations with high oxygen demands.

4.2 Payback Period

The payback period is the time it takes for your investment in a PSA oxygen generator to pay for itself. For many aquaculture farms, this period is relatively short, especially when compared to ongoing expenses for liquid oxygen.

Typical Payback Period: Depending on the size of the operation and frequency of oxygen usage, the payback period for a PSA generator is usually between 2-3 years. Larger operations with higher oxygen needs may see a quicker return on investment, while smaller farms may take a little longer.

Factors Influencing Payback: The payback period is heavily influenced by:

The scale of the farm and its oxygen consumption

The current cost of liquid oxygen and transportation

Local energy prices and efficiency of the PSA system

Maintenance and operation costs

For example, a mid-sized farm using approximately 10 tons of oxygen per year could save anywhere from $20,000 to $30,000 annually on oxygen costs alone, accelerating the return on investment.

4.3 Maintenance Costs

While PSA oxygen generators are generally low-maintenance systems, they do require periodic upkeep to ensure optimal performance and longevity.

Routine Maintenance: This includes replacing air filters, checking valves, ensuring the compressor is running efficiently, and inspecting the system for wear and tear. Regular servicing can prevent downtime and ensure continuous operation, making the system highly reliable in the long term.

Maintenance Costs Overview: Annual maintenance costs typically range from $1,000 to $5,000, depending on the system’s complexity and scale. For larger operations, maintenance costs may increase slightly, but they remain far lower than the costs of liquid oxygen delivery.

Service Life: PSA oxygen generators are built to last, with proper maintenance extending their life to 15-20 years or more. This longevity makes the system a wise long-term investment, especially when compared to the recurring delivery costs and service contracts for liquid oxygen.

4.4 Real-World Examples: ROI in Aquaculture Operations

The return on investment (ROI) of a PSA oxygen generator is often seen through increased operational efficiency, better fish health, and long-term savings on oxygen.

Case Study 1: A large fish farm in Southeast Asia adopted a PSA oxygen generator and saw a 48% reduction in oxygen supply costs within the first year. Not only did this reduce reliance on external suppliers, but it also enabled them to maintain stable oxygen levels throughout the year, improving fish growth rates and reducing mortality.

Case Study 2: A shrimp farming operation in South America installed a PSA oxygen system and achieved a payback period of 2.5 years. The farm also reported increased shrimp growth and reduced disease outbreaks, which significantly enhanced profitability.

Case Study 3: A medium-sized tilapia farm in North America chose to invest in a PSA oxygen generator and saw a 40% improvement in energy efficiency, resulting in reduced overall operational costs.

| Feature | PSA Oxygen Generator | Liquid Oxygen (LOX) | Bottled Oxygen Cylinders |

|---|---|---|---|

| Source | Produced on-site from air | External delivery required | External delivery required |

| Operational Cost | Low (Electricity only) | High (Market price + Delivery) | Very High |

| Convenience | Fully automated, 24/7 | Manual monitoring of levels | Frequent manual handling |

| Safety | Low pressure, no explosion risk | High pressure, cryogenic risk | High pressure handling risk |

| ROI | Typically 12-24 months | No ROI (Ongoing expense) | No ROI |

5. Common Issues and Solutions

Aquaculture businesses investing in PSA (Pressure Swing Adsorption) oxygen generators might face some challenges that need careful attention. Here are some of the most common issues along with practical solutions to overcome them:

Issue 1: Oxygen Shortage or Inconsistent Output

A common issue with oxygen generation systems, especially in large-scale aquaculture operations, is the occurrence of oxygen shortages or inconsistent output, which could directly affect fish health and production capacity. Fluctuations in oxygen supply, if not managed properly, can lead to poor farm performance and even loss of stock.

Solution: To address this challenge, it is critical to implement periodic system checks and ensure that regular maintenance schedules are followed. Scheduled inspections and real-time monitoring can catch potential problems before they lead to system failures.

Redundancy options such as backup oxygen generation units or additional storage tanks should be considered for large-scale operations. This ensures continuous oxygen supply even if one unit goes offline or there are temporary issues.

Automated control systems with alert features can also help in providing early warnings and preventing unexpected shortages.

Issue 2: High Initial Capital Cost

The high upfront cost of purchasing and installing a PSA oxygen generator is one of the most significant barriers for many aquaculture businesses, especially smaller farms. These systems can range from $50,000 to $300,000, depending on the capacity, leading to a large financial commitment.

Solution: To alleviate the financial burden, consider financing options or leasing programs that can ease the initial investment cost. Many manufacturers, including MINNUO, offer flexible payment plans, allowing businesses to spread the cost of the system over several years.

Additionally, looking into government subsidies or local financing programs for sustainable investments in agriculture can help reduce the overall capital expenditure. In some regions, incentives are available for businesses that invest in eco-friendly or energy-efficient solutions.

Issue 3: Energy Costs

Energy consumption is a significant operational cost for PSA oxygen generators. Farms located in regions with high energy prices can find it challenging to maintain profitability when the system consumes large amounts of electricity, particularly during peak hours.

Solution: To minimize energy costs, it is essential to optimize the generator’s usage to avoid over-production.

Use smart scheduling systems that allow the generator to operate during off-peak hours, taking advantage of lower electricity prices.

Renewable energy sources such as solar or wind power can be integrated with the PSA system to reduce reliance on the grid. Solar panels, for example, can offset the generator’s energy use during the daytime, making the system more sustainable and cost-effective in the long run.

6. How MINNUO’s PSA Oxygen Generators Benefit Aquaculture Farms

MINNUO offers a highly specialized solution for aquaculture operations with its PSA (Pressure Swing Adsorption) oxygen generators. Designed to meet the unique challenges of aquaculture, MINNUO’s systems offer tailored, cost-effective, and scalable solutions, ensuring uninterrupted oxygen supply at a reduced cost.

Tailored Solutions

MINNUO’s PSA oxygen generators are specifically customized to meet the varied demands of aquaculture. These systems are designed to integrate seamlessly with existing operations, making them an excellent choice for both new and expanding farms. The focus on cost-efficiency allows clients to reduce reliance on expensive third-party oxygen delivery methods, while the scalability ensures the system can grow with the farm’s increasing needs. Whether for small-scale hatcheries or large commercial fish farms, MINNUO provides the right solution for every operation.

Key Advantage: With flexible configurations, MINNUO offers scalable solutions to match the exact capacity needs of the farm, ensuring that farms never overpay for excess capacity or suffer from insufficient supply.

Advanced Features

MINNUO’s PSA oxygen generators incorporate cutting-edge technologies to enhance operational efficiency:

Smart Monitoring Systems: These systems allow operators to track oxygen levels in real-time, helping to optimize oxygen production and reduce waste. Automated data logging helps identify trends and predict system maintenance, which reduces operational interruptions and enhances system longevity.

Energy-Efficient Designs: MINNUO’s generators are built with energy-saving features that lower electricity consumption while maintaining high output. This is crucial for long-term cost reductions in aquaculture operations, where energy consumption can quickly escalate.

Low-Maintenance Technologies: MINNUO’s systems are designed with ease of maintenance in mind. Low-maintenance components reduce downtime and operational costs, ensuring that the farm can keep running smoothly without frequent repairs or maintenance cycles.

Key Advantage: These advanced features result in minimal downtime, maximizing productivity and ensuring the system is always ready when needed.

Customer Testimonials and Case Studies

Real-world examples of successful implementations further demonstrate the value MINNUO’s PSA oxygen generators provide to aquaculture farms. Numerous customers have reported significant improvements in fish productivity and water quality after integrating the technology.

Case Study: A large fish farm in South America installed MINNUO’s PSA generator and reported a 20% increase in fish growth rates and a noticeable improvement in water clarity. By continuously monitoring oxygen levels, the farm maintained optimal conditions for its fish, leading to higher yields and better water quality.

Customer Quote: “MINNUO’s PSA oxygen generator has drastically reduced our operational costs and improved fish health. The energy-efficient design ensures we’re saving on electricity, while the smart monitoring system lets us keep everything running at peak efficiency.”

Frequently Asked Questions:

Q: How much oxygen does a fish farm or salmon farm need?

A: Oxygen demand depends on fish density, species, and water temperature. Generally, maintaining DO levels at 6-8 mg/L is ideal for growth.

Q: Can an onsite aquaculture oxygen generator be integrated with RAS?

A: Yes, our PSA systems are designed for seamless integration with Recirculating Aquaculture Systems (RAS) to maintain precise oxygen saturation.

Q: What is the purity of oxygen produced?

A: Our systems typically produce 93%±3% purity oxygen, which is perfect for fish metabolic needs and cost-efficiency.

Conclusion

In conclusion, PSA (Pressure Swing Adsorption) oxygen generators offer a cost-effective and sustainable solution for aquaculture businesses seeking to improve fish health and productivity. By ensuring a continuous, on-demand supply of high-purity oxygen, PSA generators directly contribute to better dissolved oxygen levels, which are crucial for the optimal growth and health of fish. Additionally, they reduce reliance on costly third-party oxygen suppliers, leading to significant long-term cost savings.

Investing in a PSA oxygen generator not only enhances the efficiency of aquaculture operations but also addresses environmental concerns by reducing the need for liquid oxygen deliveries and minimizing operational costs. With the added benefits of low maintenance and energy-efficient designs, PSA generators are an excellent choice for businesses looking to improve both their profitability and sustainability.

If you’re considering a smarter, more cost-effective solution for your aquaculture operations, now is the time to act. MINNUO offers customized PSA oxygen generators designed to meet the unique needs of aquaculture businesses, with tailored solutions, expert system installations, and ongoing support. Reach out to MINNUO today to explore how our generators can help you boost fish health, cut operational costs, and take your aquaculture business to the next level.

sales2:+86 17506119168

sales2:+86 17506119168