In today’s increasingly competitive printing industry, achieving breakthroughs in both production efficiency and product quality has become the focus of many enterprises.

With deep expertise in nitrogen generation technology, Minnuo has developed an independently engineered PSA (Pressure Swing Adsorption) Nitrogen Generator, delivering ultra-high-purity nitrogen up to 99.999%. This provides a highly efficient and stable solution for printing enterprises.

This article explores in depth the applications, selection criteria, operaThe Minnuo PSA Nitrogen Generator delivers 99.999% high-purity nitrogen to enhance printing efficiency, reduce costs, and ensure superior product quality.

tional maintenance, profitability, and professional engineering insights related to Minnuo PSA Nitrogen Generators in the printing industry — helping printing enterprises seize new growth opportunities.

I. Deep Application of Minnuo PSA Nitrogen Generators in the Printing Industry

(1) Accelerating Ink Drying and Curing to Boost Printing Efficiency

In the printing process, the drying and curing speed of ink directly affects production efficiency and product quality. Traditional drying methods are often limited by environmental factors, resulting in uneven or slow drying.

The 99.999% ultra-high-purity nitrogen produced by Minnuo PSA generators creates an almost oxygen-free environment that dramatically accelerates the ink curing process.

For example, in UV printing, oxygen inhibits the photopolymerization of UV inks, leading to insufficient curing, sticky surfaces, or smudging. By introducing Minnuo’s nitrogen generator, the oxygen concentration in the UV curing chamber can be reduced below 0.001%, increasing curing speed by 50%–80%.

A large packaging printer that adopted Minnuo’s nitrogen system reduced UV curing time from 20 minutes to just 8 minutes — a 40% increase in daily output — while the defect rate dropped from 8% to below 1%, significantly improving efficiency and quality.

In flexographic and gravure printing, high-purity nitrogen also accelerates water evaporation in water-based inks, preventing smearing and blurring caused by delayed drying, ensuring print clarity and consistent production.

(2) Preventing Material Oxidation and Ensuring Product Quality

Paper, plastic films, and metal foils are highly susceptible to oxidation during storage and printing, leading to aging, discoloration, or reduced performance.

The chemically inert nitrogen produced by Minnuo PSA generators effectively isolates oxygen and protects materials throughout the entire process.

For paper storage, introducing Minnuo nitrogen into warehouses or sealed packaging maintains ultra-low oxygen levels, preventing oxidation and moisture damage.

A publishing printer extended paper shelf life from 6 months to 18 months, maintaining whiteness and strength, while print waste dropped by 70%.

For plastic film and foil printing, nitrogen prevents oxidation and ensures color vibrancy — one label printer reduced PET film rejects from 6% to 0.5%, significantly improving market competitiveness.

(3) Enhancing Equipment Stability and Reducing Downtime

High-speed printing equipment generates friction and static electricity, which attract dust and cause print defects or mechanical failures.

The dry, high-purity nitrogen from Minnuo systems neutralizes static electricity, reduces humidity, and removes dust buildup, keeping equipment clean and stable.

After integrating Minnuo nitrogen into key components, one large commercial printer reduced static-related defects from 5% to 0.8%, decreased machine failures by 60%, and lowered maintenance costs.

Additionally, using nitrogen instead of compressed air in pneumatic systems prevents corrosion and wear, improving overall reliability and ensuring continuous, efficient production.

(4) Expanding Multi-Scenario Applications Across the Industry

Beyond core processes, Minnuo PSA nitrogen generators offer multiple additional benefits.

In printed packaging, high-purity nitrogen creates a low-oxygen environment inside containers, inhibiting microbial growth and extending shelf life.

A food packaging printer extended product shelf life by 50% and reduced customer complaints by 80%.

In flammable ink or solvent printing (e.g., gravure), nitrogen helps adjust workshop atmosphere composition, lowering oxygen levels to prevent fire and explosion risks, providing a solid foundation for production safety.

II. Key Factors When Choosing a Minnuo PSA Nitrogen Generator for Printing Plants

(1) Precisely Matching Purity and Flow Requirements

Different printing processes require varying nitrogen purity and flow rates.

Minnuo’s 99.999% purity perfectly meets the demands of high-end UV printing, ensuring complete curing and premium print quality.

For flexo or offset printing, the same high purity enhances drying efficiency and material protection.

The flow rate must align with plant scale and workload. Minnuo’s engineering team offers custom modular solutions, allowing flexible capacity adjustments and 20–30% reserve flow for future expansion — maximizing cost-effectiveness.

(2) Prioritizing Equipment Stability and Reliability

Printing production requires continuous operation — nitrogen system failures can cause major losses.

As an industry-leading manufacturer, Minnuo integrates patented technologies and strict quality control across its systems.

Core components include:

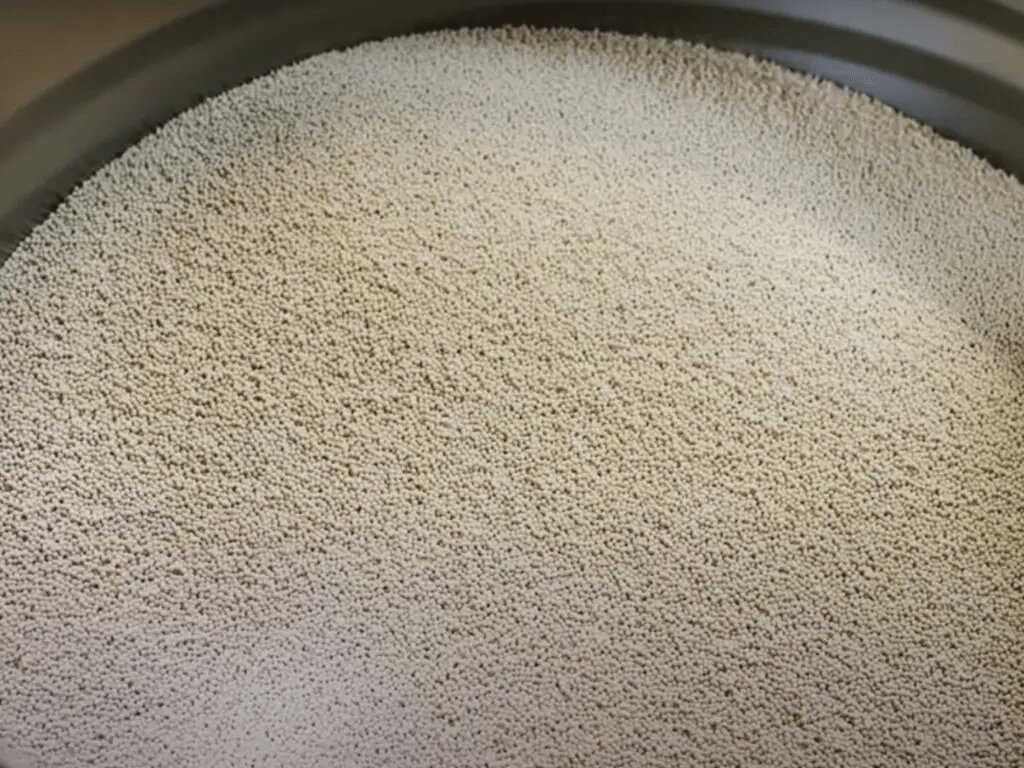

- Proprietary high-capacity adsorbents with long service life and strong selectivity;

- High-precision valves tested for over a million cycles without leakage;

- Variable-frequency compressors for stable power;

- Smart monitoring and automatic control for real-time performance stability.

Minnuo also provides comprehensive after-sales support: 24-hour repair response, on-site service within 48 hours, and scheduled maintenance visits — ensuring continuous uptime and minimized production interruptions.

(3) Evaluating Energy Efficiency and Operating Costs

Energy consumption is a key cost factor in PSA nitrogen generation.

Minnuo systems combine advanced PSA + vacuum desorption technology with intelligent controls and high-efficiency adsorbents, achieving 30%–40% lower energy use than traditional units.

Its adsorbent lifespan reaches 8–10 years, and standardized spare parts are durable and affordable.

Remote monitoring and predictive maintenance features further reduce unplanned downtime.

Overall, Minnuo PSA nitrogen generators deliver substantial operational savings and long-term profitability.

III. Daily Operation and Maintenance Guidelines

(1) Implement Scheduled Maintenance

To ensure stable nitrogen purity and equipment reliability, regular maintenance per the operation manual is essential.

Check compressors, towers, and valves periodically; replace worn parts; regenerate or replace adsorbents; clean filters to maintain flow and purity.

Minnuo offers on-site technical guidance, maintenance kits, and cost-effective service plans to simplify upkeep.

(2) Monitor Key Operating Parameters

Pressure, flow, and purity directly indicate machine performance.

Minnuo’s smart control panel provides real-time data and alarms — e.g., alerts for purity drops, flow instability, or valve faults.

Cloud-based data logging supports performance tracking and optimization, ensuring optimal operation at all times.

(3) Standardize Operating Procedures

Trained operators are vital for long-term stability.

Before startup, check power, air, and connections; follow proper shutdown steps to prevent damage.

Maintain detailed operation logs — including runtime, parameters, and maintenance records — to identify trends and prevent issues.

Minnuo provides professional training, both online and offline, to enhance staff expertise.

IV. Core Profitability Values for Printing Enterprises

(1) Significantly Boosting Production Efficiency

By accelerating curing and improving equipment stability, Minnuo nitrogen systems greatly enhance production throughput.

In UV printing, curing time is cut in half; fewer stoppages on high-speed lines increase total output.

A user reported 50% higher productivity and hundreds more daily orders — driving both volume and revenue growth.

(2) Effectively Reducing Production Costs

High-purity nitrogen reduces material oxidation and extends shelf life, lowering procurement costs.

Fewer breakdowns and lower energy use further reduce labor and maintenance expenses.

Overall, Minnuo nitrogen systems can reduce total production costs by 20–30%, improving price competitiveness and profit margins.

(3) Enhancing Product Quality and Brand Value

Operating in a high-purity nitrogen environment ensures vivid colors, sharp details, and flawless surfaces — meeting premium market standards.

This consistency enhances customer satisfaction and loyalty.

Several users have leveraged superior print quality to attract high-end clients and achieve 40% profit growth.

V. Professional Recommendations from Minnuo Engineers

As experienced engineers from Minnuo’s PSA nitrogen generator division, we offer the following practical guidance:

- Plan installation scientifically:

Install in a well-ventilated, dry area free from corrosive gases, heat, or vibration.

Allow sufficient space for operation and maintenance — Minnuo provides detailed installation support. - Invest in operator training:

Skilled operators extend equipment lifespan and efficiency.

Minnuo offers regular professional training sessions (online and onsite) to enhance technical capabilities. - Establish emergency backup plans:

Though Minnuo systems are highly reliable, prepare spare nitrogen sources or backup units to ensure continuous operation during maintenance.

Our engineers can assist in designing contingency plans. - Stay updated with technology upgrades:

PSA technology evolves rapidly — stay informed about Minnuo’s latest advancements to maintain competitiveness through timely system upgrades.

Conclusion

With its 99.999% ultra-high-purity nitrogen, stable and intelligent performance, and comprehensive technical support,

the Minnuo PSA Nitrogen Generator has become the trusted choice for printing enterprises striving for higher quality and efficiency.

If you’re interested in learning more about its applications in the printing industry or wish to discuss your specific requirements,contact Minnuo today — our experts are ready to deliver professional, efficient solutions to help you drive the next phase of high-quality growth in printing.

sales2:+86 17506119168

sales2:+86 17506119168