In the modern industrial system, the metallurgical industry plays a vital role as a cornerstone of the national economy. It provides key raw materials for construction, machinery, automotive, aerospace, and other sectors. However, metallurgical production involves complex and demanding processes—from ore sintering, blast furnace ironmaking, converter steelmaking to rolling—which place stringent requirements on production environments and gas quality.

Among the process gases used, nitrogen, as an inert gas with stable chemical properties and low reactivity, has become an indispensable protector and enabler in metallurgical production. As a leading nitrogen generation solution, Minnuo’s PSA nitrogen generators deliver high efficiency, energy savings, and stable performance, providing strong support for the high-quality development of the metallurgical industry.

I. Why is High-Quality Nitrogen Essential for the Metallurgical Industry?

Metallurgical production involves high temperatures, high pressures, and intense chemical reactions. Metals are prone to oxidation and nitridation reactions with oxygen and moisture in the air, leading to degradation in material properties, lower product pass rates, and even safety risks. Nitrogen plays a critical role in mitigating these problems.

In the sintering process, nitrogen is used for sintered ore cooling. Traditional air cooling can oxidize the ore surface, forming a hard oxide layer that reduces strength and permeability, while increasing energy consumption in the subsequent ironmaking process. Nitrogen cooling effectively isolates oxygen, reduces oxidation loss, improves ore quality, and enables recovery of heat for energy recycling.

In blast furnace ironmaking, nitrogen plays a dual role: sealing high-temperature gas inside the furnace and replacing explosive gas mixtures during shutdown and restart (blow-in/blow-out). Additionally, nitrogen injection into the furnace improves gas flow distribution, enhances ironmaking intensity, increases pig iron output, and reduces coke consumption.

In converter steelmaking, nitrogen is used both for stirring and as a protective atmosphere. Injecting nitrogen into the converter promotes mixing of molten steel and slag, accelerates reactions, enhances uniformity of composition and temperature, reduces non-metallic inclusions, and improves molten steel quality. During pouring, nitrogen shields the molten steel from reoxidation, ensuring casting quality and performance.

During rolling, nitrogen assists in cooling, rust prevention, and protection. In hot rolling, nitrogen regulates cooling rates to improve microstructure, strength, and toughness. In cold rolling, it cools and lubricates equipment and steel surfaces. For heat treatment, nitrogen acts as a protective atmosphere to prevent oxidation and decarburization, ensuring process quality.

Clearly, high-quality nitrogen is indispensable in every stage of metallurgical production. Thus, reliable and efficient nitrogen generation equipment is critical for maintaining uninterrupted and stable operations.

II. PSA Nitrogen Technology: The Ideal Solution for Metallurgical Applications

Currently, industrial nitrogen generation technologies include cryogenic air separation, pressure swing adsorption (PSA), and membrane separation.

Cryogenic separation is mature and produces large volumes but requires high investment, large footprint, and long startup times—suitable for large-scale, continuous nitrogen demand.

Membrane separation systems are compact and easy to operate but involve high membrane costs, shorter lifespan, and lower nitrogen purity.

PSA nitrogen generation, by contrast, offers low investment, small footprint, fast startup, adjustable purity, and user-friendly operation—making it ideal for small to medium-scale nitrogen needs in metallurgy.

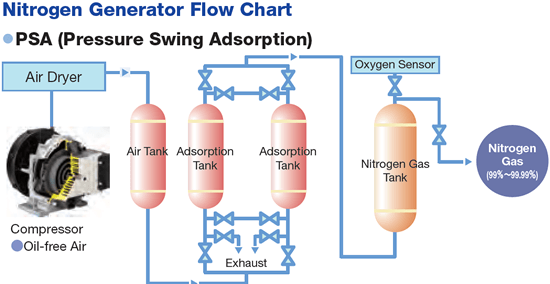

How PSA Works:

PSA technology uses selective adsorption by molecular sieves (such as carbon molecular sieve) under pressure to separate nitrogen from air. Oxygen, CO₂, and water vapor are preferentially adsorbed, while nitrogen is enriched and delivered as product gas. Once saturation is reached, pressure is lowered to regenerate the adsorbent. This cycle repeats continuously.

Minnuo’s PSA nitrogen generators are built on this core principle but further optimized for the metallurgical sector, delivering superior performance tailored to real-world production needs.

1. High Efficiency and Energy Savings

Minnuo PSA generators use high-performance carbon molecular sieves with large adsorption capacity, high selectivity, and long service life. This ensures high nitrogen yield and purity at reduced energy consumption. The system’s advanced control algorithms automatically adjust operation parameters based on production demand, allowing precise control of purity and flow rate. Compared to traditional cryogenic systems, Minnuo’s PSA units reduce energy use by over 30%, significantly lowering operating costs.

2. Stable and Reliable Operation

With a compact modular design, Minnuo PSA generators occupy minimal space, are easy to install, and can be quickly commissioned. Key components, such as solenoid valves, adsorption towers, and pressure gauges, are sourced from trusted global brands, ensuring long-term operational stability. The system includes real-time fault diagnosis and alarm features to monitor performance, detect issues early, and maintain continuous operation—minimizing production downtime.

3. Adjustable Nitrogen Purity

Minnuo’s PSA systems can flexibly adjust nitrogen purity between 95% and 99.999%, meeting varied requirements across different stages of production:

99.9%+ for sealing and purging in blast furnaces

Around 99.5% for stirring in converter steelmaking

99.99%+ for protective atmospheres in heat treatment

This versatility is achieved through a combination of precise process control and high-quality adsorbents, ensuring consistent gas supply for critical applications.

4. Easy Operation and Low Maintenance

The system is equipped with a user-friendly interface, requiring minimal training for operators. Routine maintenance involves periodic replacement of adsorbents and inspection of valves and gauges—simple and cost-effective. Compared to membrane systems, Minnuo’s adsorbent lifespan is 3–5 years, significantly reducing maintenance costs and downtime.

III. Minnuo PSA Solutions for the Metallurgical Industry

As a dedicated PSA nitrogen generator manufacturer, Minnuo provides high-quality, tailored nitrogen solutions for metallurgical customers. With deep understanding of production processes and gas requirements, we deliver scalable and customized solutions to meet unique operational needs.

A. Comprehensive Solutions for Large Steel Plants

Large-scale steel enterprises often have multiple nitrogen demand points, with varied flow and purity requirements. Minnuo offers integrated solutions using multiple PSA units distributed across production areas, minimizing pressure loss during gas transport and reducing energy consumption. A centralized control system synchronizes operation across all units, ensuring coordinated supply.

Case Example:

A large steel group operating two blast furnaces, three converters, and several rolling lines required high nitrogen volume and multiple purity levels. Minnuo supplied five PSA generators:

Two units supplying 99.9% nitrogen for blast furnace sealing

Two units providing 99.5% nitrogen for converter stirring

One unit delivering 99.99% nitrogen for rolling and heat treatment

The centralized system dynamically adjusted flow rates and purity based on real-time demand, resulting in stable nitrogen supply, reduced energy use, and improved economic efficiency.

B. Cost-Effective Solutions for Small and Medium Enterprises (SMEs)

SMEs typically have moderate nitrogen needs and are more cost-sensitive. Minnuo provides economical PSA solutions by optimizing component selection and system configuration, reducing investment without compromising performance. Flexible installation options ensure fast deployment and short commissioning times.

Case Example:

A small casting company required nitrogen for casting and heat treatment. Minnuo installed a compact PSA generator producing 50 Nm³/h at 99.9% purity, directly within the production facility. This eliminated reliance on external nitrogen supply, reduced costs, and enhanced product quality and operational efficiency.

C. Customized Solutions for Special Metallurgical Processes

Specialty metallurgical applications such as stainless steel or alloy production demand ultra-high purity nitrogen with strict moisture and oxygen limits. Minnuo’s engineering team works closely with clients to design bespoke systems.

Case Example:

A stainless steel producer required nitrogen with purity of 99.9995%, moisture below -60°C, and oxygen content under 1 ppm. Minnuo delivered a PSA system with advanced drying and purification stages, meeting all technical specifications. The solution improved product quality, reduced scrap rates, and delivered strong ROI.

IV. Minnuo PSA Nitrogen Generators: Trusted Quality and Service Excellence

In a competitive market, Minnuo adheres to the principles of “Quality First, Customer Foremost,” continuously enhancing product performance and customer service.

A. Strict Quality Control

From raw material sourcing to final shipment, Minnuo maintains a rigorous quality assurance system.

Suppliers are carefully vetted to ensure material quality

Advanced production equipment and process controls ensure precision manufacturing

Each unit undergoes comprehensive performance testing (purity, flow rate, pressure, energy use)

Final packaging and labeling ensure product integrity during transportation

B. Dedicated R&D Team

Minnuo’s R&D team combines deep expertise in PSA technology and metallurgical processes. Constant innovation has led to the development of energy-efficient, intelligent-control, and low-energy PSA models—widely adopted and highly rated by customers across the industry.

C. Comprehensive After-Sales Support

Minnuo provides end-to-end service to ensure long-term system reliability:

On-site guidance for installation and commissioning

Scheduled inspections and preventive maintenance

Rapid response for fault repairs

Technical training for operators to maximize equipment lifespan and efficiency

V. Looking Ahead: Driving Green Manufacturing in Metallurgy

With national carbon neutrality goals and industrial transformation accelerating, the metallurgical sector is embracing energy-efficient and environmentally friendly production models. As a key equipment supplier, Minnuo is committed to ongoing R&D investments to enhance PSA nitrogen systems with higher efficiency and sustainability.

Going forward, Minnuo will strengthen collaboration with industry partners to better understand emerging needs and pain points, delivering more customized, intelligent nitrogen solutions. The company will also explore integration of PSA systems with renewable energy and digital technologies, driving intelligent and green transformation in gas supply for metallurgy.

Minnuo PSA Nitrogen Generators — the reliable partner for efficient metallurgical production. Choosing Minnuo means choosing stability, efficiency, and a future of smart manufacturing. Let’s work together to open a new chapter in green, intelligent metallurgy.

sales2:+86 17506119168

sales2:+86 17506119168