In the industrial gas production sector, equipment flexibility, stability, and energy costs directly determine operational efficiency. With over 30 years of expertise in air separation technology, Jiangsu Minnuo Group has launched containerized liquid nitrogen (LN2) equipment that integrates modular design, cryogenic air separation processes, and intelligent control technology, becoming the preferred solution for medical, food, manufacturing, and other industries .

1. Containerized Design: Dual Breakthroughs in Convenience and Safety

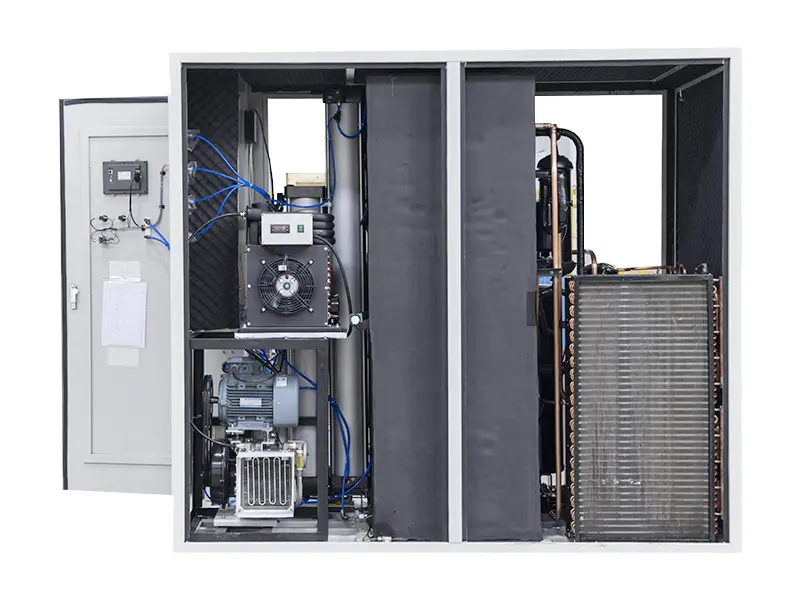

Minnuo’s containerized LN2 equipment adopts ISO standard container structure, constructed with low-temperature resistant stainless steel, equipped with high-efficiency insulation layers and multiple safety devices, enabling stable operation at ultra-low temperatures of -196℃ . Its core advantages include:

- Plug-and-play flexibility: The integrated system combines PSA nitrogen generator, cryogenic refrigerator, and built-in dewar tank, covering only 85-410㎡. No complex infrastructure is required, and nitrogen production can start within 10-15 minutes after installation ;

- Multi-scenario adaptability: Compatible with road, railway, and maritime transportation, it can be quickly deployed in remote mining areas, temporary construction sites, or emergency medical scenarios to meet mobile production needs;

- Safety redundancy design: Equipped with pressure relief valves and MCGS remote monitoring system, it tracks temperature and pressure data in real-time and triggers automatic fault alerts, eliminating vaporization explosion risks from the source .

2. Core Performance: Perfect Balance of Stable Output and Energy Efficiency

As a professional air separation equipment manufacturer, Minnuo achieves performance breakthroughs through process optimization:

- Stable productivity: LN2 output ranges from 100L/h to 2000L/h, with nitrogen purity up to 99.999% and stable pressure at 0.34-1MPa, satisfying applications from laboratory precision needs to large-scale industrial production ;

- Industry-leading energy control: Adopting high-efficiency heat exchangers and intelligent standby mode, the system automatically shuts down when the built-in dewar tank is full, reducing energy consumption by over 30% compared to traditional equipment and saving nearly 50% in gas costs during long-term operation ;

- Minimal maintenance: The fully enclosed integrated design allows easy replacement of key components. Combined with remote maintenance systems, fault diagnosis and program upgrades can be completed online, with annual maintenance required less than twice .

3. Multi-industry Application: Practical Verification of Industrial Upgrading

Minnuo‘s containerized LN2 equipment has been successfully applied in dozens of global projects:

- Medical field: Provides -196℃ cryogenic storage for biobanks, ensuring the viability of cells and organs, suitable for hospitals and research institutions ;

- Food industry: Enables rapid freezing of seafood and baked goods, maintaining freshness and texture through precise temperature control, helping food enterprises obtain cold chain quality certification ;

- High-end manufacturing: Offers cryogenic cooling for metal processing, enhancing workpiece strength and wear resistance, serving precision manufacturing sectors like auto parts and aerospace .

sales2:+86 17506119168

sales2:+86 17506119168