Introduction: The Silent Vulnerability in Your Production Line

Picture this: a forecasted snowstorm has grounded all deliveries, and your last tank of liquid nitrogen is dipping into the red. Your flash-freezing line, a critical piece of your food processing plant, is hours away from a complete and costly shutdown. This isn’t just an inconvenience; it’s a direct threat to your revenue and reputation.

For countless manufacturers, this scenario is a recurring nightmare. Reliance on delivered liquid nitrogen (LN2) means entrusting your most critical processes to factors beyond your control—weather, traffic, and supplier reliability. But what if you could eliminate this vulnerability entirely?

The solution isn’t a better delivery contract; it’s eliminating the delivery itself. On-site nitrogen generation is the strategic shift that turns a fragile supply chain into a pillar of operational resilience.

The Three Core Hazards of Liquid Nitrogen Delivery

To appreciate the solution, we must first understand the full scope of the problem. Traditional liquid nitrogen supply is fraught with hidden risks that impact your safety, efficiency, and bottom line.

Hazard #1: The Supply Chain “Ticking Time Bomb”

Your production schedule shouldn’t be at the mercy of external logistics.

- Weather & Disruptions: A single snowstorm, flood, or traffic accident can halt deliveries, idling your production line.

- Supplier Issues: Production outages at your gas supplier’s facility immediately become your problem.

- The “Just-in-Time” Jeopardy: The modern lean manufacturing model leaves zero room for error. One missed delivery can trigger a cascade of production delays and missed order deadlines.

Hazard #2: The Safety and Handling “Minefield”

Liquid nitrogen, at a chilling -196°C (-321°F), is inherently dangerous to handle.

- Cryogenic Burns: A single splash during transfer or decanting can cause severe frostbite and tissue damage in seconds.

- Asphyxiation Risk: LN2 rapidly expands to 700 times its volume as gas. A leak in a confined space can displace oxygen, creating a lethal, oxygen-deficient atmosphere.

- Pressure Hazards: Improper handling or storage can lead to pressure build-up and potential vessel rupture.

Hazard #3: The Financial “Silent Leak”

The true cost of LN2 is far more than the price on the invoice.

- Boil-Off Losses: This is the single biggest financial drain. Even in a perfectly insulated tank, liquid nitrogen continuously evaporates. Industry estimates suggest losses of 1% to 3% per day are standard. You are literally watching your money evaporate into thin air.

- Delivery Surcharges: Emergency deliveries, remote location fees, and fuel surcharges make your monthly costs unpredictable.

- Hidden Operational Costs: The labor required to manage inventory, schedule deliveries, and perform safety checks during unloading adds up significantly.

The Paradigm Shift: A Data-Driven Comparison

The following table summarizes the compelling case for making the switch, transforming risks into resilience.

| Comparison Dimension | Liquid Nitrogen Delivery | On-Site Nitrogen Generation |

| Supply Reliability | Dependent on logistics & weather | 24/7 on-demand, no disruptions |

| Safety Risks | Cryogenic burns, asphyxiation, pressure hazards | Eliminates high-risk cryogenic handling |

| Boil-Off Losses | 1-3% daily (10-30% annual) | Zero evaporation losses |

| Cost Predictability | Unstable (surcharges, emergency fees) | Stable (electricity as main cost) |

| ROI Period | N/A (ongoing expenses) | 18-36 months (typical) |

How On-Site Generation Eliminates These Hazards

On-site nitrogen generation severs your dependence on the delivery truck, transforming your nitrogen supply from a liability into a controlled, reliable utility.

Solution to Hazard #1: Unbreakable Supply Chain Resilience

With an on-site generator, the air around your facility becomes your raw material. You produce high-purity nitrogen gas on-demand, 24/7. There are no more delivery schedules, no more weather delays, and no more supplier shortages. You take full control of your production destiny.

Solution to Hazard #2: Inherently Safer Operations

By switching to on-site generation, you eliminate the most dangerous steps in the LN2 lifecycle: the transportation, unloading, and high-volume storage of a cryogenic liquid. This dramatically reduces the risk of cryogenic burns and large-scale asphyxiation hazards, creating a fundamentally safer work environment.

Solution to Hazard #3: Predictable and Slashed Costs

- Eliminate Boil-Off: On-site systems produce nitrogen gas, which does not evaporate. This alone can save you the 10-30% of product that was previously lost.

- Cost Predictability: Your primary cost becomes electricity, which is stable and manageable. Say goodbye to unpredictable monthly gas bills and hidden fees.

- Total Cost of Ownership (TCO): While there is an upfront investment, the dramatic reduction in operational expenses (OpEx) typically leads to a compelling ROI, with many systems paying for themselves in 18-36 months.

Case in Point: A Food Processing Plant’s Transformation

Challenge

A frozen food manufacturer relied on weekly LN2 deliveries for its spiral freezers. They faced constant anxiety over delivery timing, incurred 15% annual losses from boil-off, and experienced two costly production halts due to winter storms—each halt resulting in $50,000+ in lost revenue and wasted inventory.

Solution

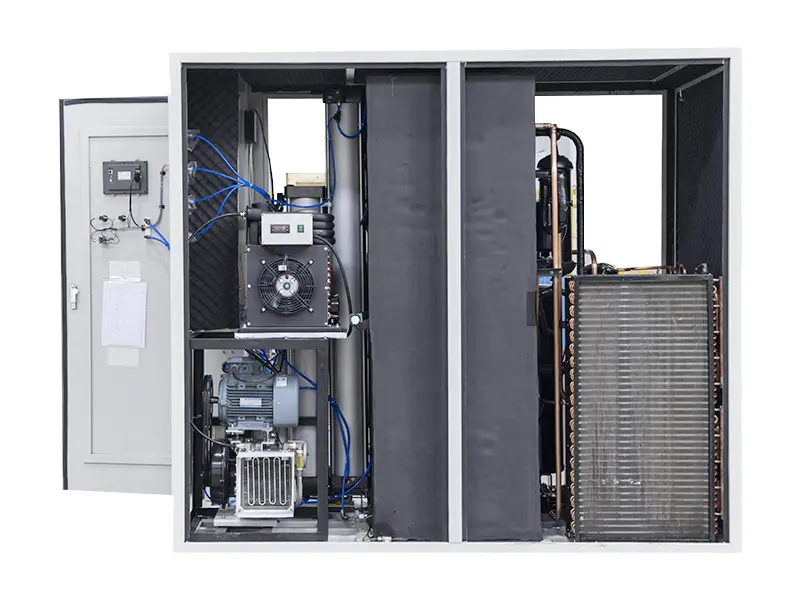

The plant installed a turnkey MINNUO on-site nitrogen generation and cooling system, tailored to their 24/7 freeze line demand of 300 Nm³/h of nitrogen at -196°C.

Results

- Eliminated Production Stoppages: Complete control over nitrogen supply, even during extreme weather events that previously grounded delivery trucks.

- Reduced Gas Costs by 40%: Savings stemmed from eliminating 15% annual boil-off losses, $12,000 in annual delivery surcharges, and $8,000 in labor costs for inventory management and unloading.

- Achieved Payback in 22 Months: The $280,000 upfront investment was fully recouped through consistent monthly savings, with projected 10-year cumulative savings exceeding $1.2 million.

Making the Right Choice: Is On-Site Generation for You?

While on-site nitrogen generation delivers remarkable resilience and cost savings as we’ve outlined, we believe in complete transparency. It is a strategic investment that delivers the highest value for operations with consistent, high-volume nitrogen demand.

There are specific scenarios where traditional supply methods may still be the more practical choice:

- Extremely Low or Intermittent Consumption: If your facility’s nitrogen usage is very low (e.g., under 500 Nm³ per month) and lacks a consistent pattern, the upfront investment in an on-site system may be difficult to justify based on ROI alone. In these cases, high-pressure nitrogen gas cylinders or a small number of liquid dewars could be a more practical near-term solution.

- Limited Capital Expenditure (CapEx) Flexibility: For businesses with tightly constrained upfront budgets, the operational expenditure (OpEx) model of delivered gas, despite its long-term higher cost, may align better with current financial planning.

- Space or Permitting Constraints: The physical footprint required for an on-site generator and the associated air compressor, though compact, may not be feasible for all facilities.

The decision ultimately hinges on a careful analysis of your Total Cost of Ownership (TCO). The tipping point typically comes when the annual cost of delivered gas (including all hidden fees and losses) begins to approach, or exceed, the annualized cost of owning and operating an on-site system.

Our goal is not to sell every manufacturer a generator, but to help every manufacturer find the most efficient and reliable gas supply solution for their unique situation.

Frequently Asked Questions

Q1: Our process requires cryogenic temperatures for freezing. How can gaseous nitrogen from an on-site generator replace liquid nitrogen?

A1: This is a common and critical question. Advanced on-site systems can be seamlessly integrated with dedicated liquid nitrogen converters or compressor-based cooling modules. These units take the high-purity gaseous nitrogen produced by the on-site generator and cool it to cryogenic temperatures (-196°C) using energy-efficient refrigeration technology. The end result is the exact same freezing performance as delivered LN2—with the added benefits of on-demand supply, zero boil-off, and no delivery-related risks.

Q2: Is the purity of on-site generated nitrogen sufficient for sensitive applications, like in the food, pharmaceutical, or electronics industries?

A2: Absolutely. Modern technologies like PSA (Pressure Swing Adsorption) and membrane separation consistently produce nitrogen with purities ranging from 95% to over 99.999%. This meets the strictest industry standards, including ISO 22000 for food processing, GMP for pharmaceuticals, and SEMI F21 for electronics manufacturing. For specialized needs—such as 99.9995% ultra-high purity nitrogen for chip packaging or inert gas blanketing in chemical processing—MINNUO systems can be customized with additional purification stages to meet your exact requirements.

Q3: What about the reliability and maintenance of the equipment?

A3: Modern on-site nitrogen generators are engineered for industrial-grade 24/7 operation. Most systems feature N+1 redundancy design—meaning one standby module is included alongside your primary units. If a primary module requires maintenance, the standby unit automatically activates, ensuring uninterrupted supply. Additionally, predictive maintenance alerts (via remote monitoring platforms) notify your team of potential issues before they cause downtime. Routine maintenance is minimal, typically limited to filter replacements every 6-12 months, with most manufacturers offering 24/7 technical support for urgent needs.

Conclusion: Make an Informed Decision for Your Operations

This guide is designed to provide manufacturers facing supply chain challenges with a comprehensive reference for decision-making. Continuing to rely on delivered liquid nitrogen means accepting unnecessary risk, hidden costs, and operational vulnerability as an unavoidable cost of doing business. But that’s simply not the case.

On-site nitrogen generation is more than an equipment upgrade—it’s a strategic decision that boosts operational resilience, enhances workplace safety, and improves long-term profitability. It’s time to stop managing delivery hazards and start manufacturing your own supply certainty.

Contact MINNUO today for a free, no-obligation Nitrogen Supply Chain Assessment. Our experts will analyze your current nitrogen usage, audit existing costs (including hidden fees and losses), and provide a detailed report outlining your potential monthly savings, ROI timeline, and customized on-site solution design.

sales2:+86 17506119168

sales2:+86 17506119168