You’ve invested in a state-of-the-art Pressure Swing Adsorption (PSA) nitrogen or oxygen generator. You follow the maintenance schedule, yet purity declines, energy use creeps up, and you face an expensive molecular sieve change years ahead of schedule. The instinct is to blame the generator or the sieve itself.

But in the vast majority of cases, this diagnosis is wrong. The real failure isn’t happening inside the adsorption towers; it’s arriving at their inlet.

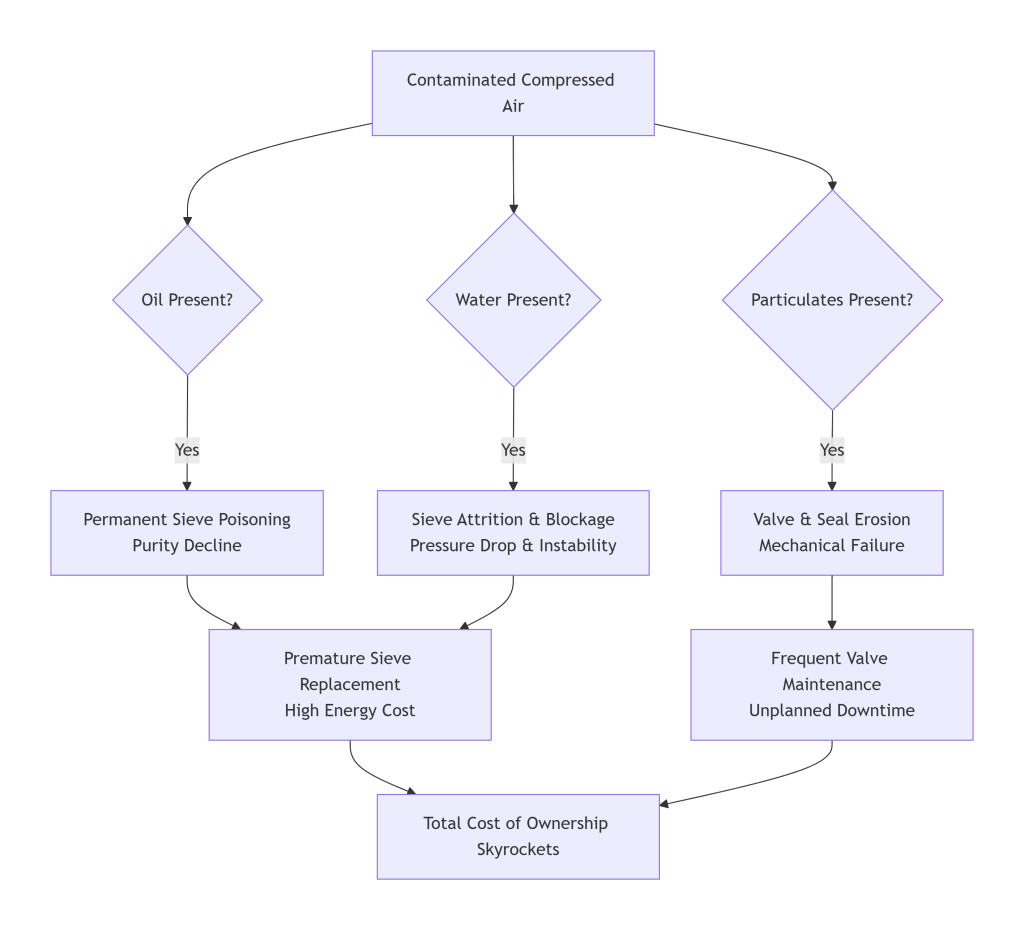

Your nitrogen or oxygen generator is only as good as the compressed air you feed it. Contaminants in this air—oil, water, and particles—act as silent, systemic poisons. They don’t cause a sudden breakdown; they orchestrate a slow, costly degradation that masquerades as normal wear and tear. Understanding this link is the single most important factor in protecting your gas generation investment.

I. The PSA System: A Sophisticated Filter with a Fatal Flaw

A PSA generator is essentially a brilliant, cyclical filter. It uses a porous adsorbent (like carbon molecular sieve or zeolite) to selectively trap nitrogen or oxygen from air under pressure. Its fatal flaw? It cannot distinguish between the target gas molecules and destructive contaminants. It will adsorb them all, and while gases like N₂ or O₂ are released during regeneration, many contaminants are not. They accumulate.

II. The Three Poisons: A Pathology Report

Let’s dissect how each contaminant attacks your system.

1. Oil: The Chronic Toxin

- The Vector: Oil aerosol and, more insidiously, oil vapour from lubricated compressors or contaminated pipelines.

- The Pathology: Oil coats the vast internal surface area of the adsorbent beads. This coating is non-reversible; standard purge cycles cannot remove it. The oil film permanently blocks adsorption sites, drastically reducing the sieve’s capacity to hold nitrogen or oxygen.

- The Symptoms: A gradual, linear decline in purity over months. You compensate by increasing purge cycles or pressure, which raises energy costs. Eventually, the sieve is “dead” and must be replaced—often at 30-50% of its expected lifespan.

- The Antidote: Class 0 oil-free compressed air is the gold standard. If using lubricated compressors, you must employ high-efficiency coalescing filters followed by activated carbon or catalytic oil vapour removal filters. Regular filter maintenance is non-negotiable.

2. Water: The Structural Saboteur

- The Vector: Liquid water and high-humidity air, resulting from inadequate drying.

- The Pathology: Water is highly polar and is fiercely adsorbed by the sieve. In PSA systems, it competes with nitrogen for sites, crippling efficiency. Worse, during the pressure swing, water can cause capillary condensation inside the sieve pores, leading to physical stress and bead fragmentation (attrition). In membrane systems, liquid water can freeze inside fibres, causing irreversible blockages.

- The Symptoms: Unstable purity, increased pressure drop across the system, and a visible reduction in sieve volume (dust in filters). Energy consumption rises sharply.

- The Antidote: Ensure your compressed air has a Pressure Dew Point (PDP) at least 10°C below the coldest ambient temperature your system will experience. For most PSA systems, this means a PDP of -20°C to -40°C or lower, typically requiring a desiccant dryer.

3. Particulates: The Abrasive Assassin

- The Vector: Rust, pipe scale, dust, and desiccant dust from upstream equipment.

- The Pathology: These hard particles act like sandpaper on the high-precision valves and seals controlling the PSA cycle. They also physically abrade the adsorbent beads, creating fines that clog downstream filters and further damage valves.

- The Symptoms: Valve failure (internal leaks) leading to cyclical purity drops, increased maintenance frequency for valve rebuilds, and rising particulate levels in downstream filters.

- The Antidote: Install a 1-micron (or finer) particulate filter immediately before the generator inlet. Ensure upstream air receivers and piping are clean and corrosion-free.

III. The Non-Negotiable Air Quality Standard for PSA Systems

To protect your investment, demand that the air supplied to your generator meets a minimum standard. We recommend ISO 8573-1:2010 Class 2.1.1 as a starting point for critical applications:

- Particle Class 2: ≤ 1 micron particle size, ≤ 100,000 particles per m³.

- Water Class 1: Pressure dew point ≤ -40°C (≤ -40°F).

- Oil Class 1: Total oil content (aerosol+vapour) ≤ 0.01 mg/m³.

IV. Your Pre-Generator Air Audit Checklist

Before you blame the generator, audit your air supply:

- Test the Dew Point: Use a portable meter at the generator inlet.

- Check Filter Status: Are pre-filters differential gauges in the red? Are they rated for oil vapour?

- Inspect for Liquid: Are there liquid drains upstream? Do they discharge water/oil?

- Review Compressor Type: Is it truly oil-free? If lubricated, what vapour control is in place?

V. Conclusion: An Integrated System, Not Isolated Silos

The performance and longevity of your nitrogen or oxygen generator are not determined at the factory. They are determined every second by the quality of air flowing into it. Viewing the air compressor, dryer, filter, and gas generator as separate silos is a costly mistake. They are one integrated life-support system.

Protecting your PSA asset requires vigilant stewardship of its entire upstream environment. The upfront cost of achieving Class 0 oil-free air and a -40°C dew point is not an expense; it is insurance for the far greater capital tied up in your gas generation system.

At MINNUO, we bring a unique perspective because we master both ends of this system. We understand the exacting purity of the PSA process and the rigorous air treatment required to sustain it. Our solutions are designed not in isolation, but as cohesive systems where the compressor plant is the foundation for flawless gas generation. Because the cleanest nitrogen or oxygen can only come from the cleanest air.

sales2:+86 17506119168

sales2:+86 17506119168