I. Core Working Principle of Membrane Nitrogen Generator in Oil Drilling Scenarios

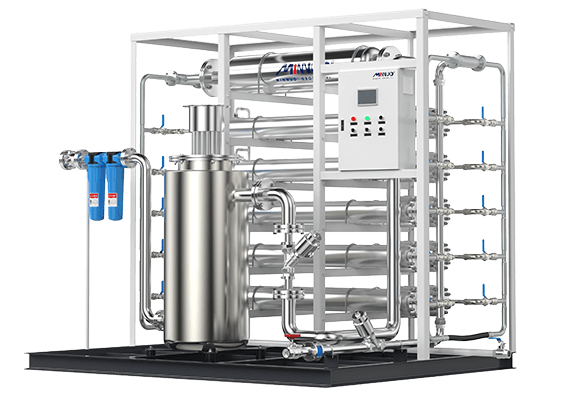

As the “safety core equipment” for oil drilling, the membrane nitrogen generator adopts a separation technology based on the core logic of gas permeability differences. The entire system consists of three closed-loop operation modules: air pretreatment, membrane separation, and automatic control:

- Raw Gas Pretreatment Stage: Compressed air at the drilling site first enters the pretreatment system. Impurities such as dust and oil are completely removed through four-stage filtration (coarse filtration → medium filtration → fine filtration → ultra-fine filtration). Then, dewatering by a cooler and constant temperature treatment by a heater are performed to ensure the intake air meets the “clean, dry, and constant temperature” standard — the dew point is ≤ -40℃ and the temperature is stabilized at around 50℃, providing optimal working conditions for membrane separation.

- Core Membrane Separation Stage: The pretreated compressed air is introduced into the composite membrane module, which contains millions of hollow fibers with a diameter of only tens of micrometers, forming a large separation area. Driven by pressure, gas molecules such as oxygen, carbon dioxide, and water vapor have high permeability rates and permeate out from the low-pressure side of the membrane wall to be discharged. In contrast, nitrogen molecules have low permeability rates and are enriched on the high-pressure inner side of the membrane tubes, ultimately forming high-purity nitrogen that is output to the gas storage tank, achieving efficient nitrogen-oxygen separation.

- Automatic Control and Regulation Stage: A PLC system is used to real-time monitor key parameters such as nitrogen purity, pressure, and temperature. When the purity fluctuates, the pressure difference of the membrane module is adjusted through a purity control valve to ensure stable output nitrogen indicators. Meanwhile, a pressure safety controller is equipped to automatically shut down the heater when the intake pressure is lower than the set value, avoiding damage to the membrane module.

II. Core Role of Key Operating Parameters: “Dual Guarantee” of Purity and Pressure

In oil drilling operations, the purity and pressure of nitrogen directly determine drilling safety, efficiency, and equipment service life, forming a “synergistic and complementary” key role:

- Purity Index: The “lifeline” of drilling safety

The requirement for nitrogen purity in oil drilling is usually ≥ 99.9%, and for special scenarios (such as high-pressure gas well drilling), it needs to reach more than 99.99%. As an inert gas, high-purity nitrogen can effectively isolate oxygen, preventing drilling fluid oxidation and deterioration, and underground natural gas combustion and explosion. If the purity is insufficient (excessive oxygen content), it will not only lead to the deterioration of drilling fluid performance but also may cause major safety accidents such as wellbore collapse and stuck pipe. The Minnuo membrane nitrogen generator uses an online oxygen analyzer for real-time monitoring, with a purity control accuracy of ±0.01%, fully meeting API oil industry standards.

- Pressure Parameter: The “power source” of operation efficiency

The working pressure of the membrane nitrogen generator for drilling needs to be dynamically adjusted according to drilling depth and formation pressure, with a conventional operating pressure range of 0.6-1.2MPa. Appropriate pressure can ensure that nitrogen is quickly injected into the wellbore, efficiently displacing natural gas in the drilling fluid and balancing formation pressure. Excessively high pressure will increase equipment energy consumption and pipeline loss, while excessively low pressure cannot meet the nitrogen supply demand for deep drilling. The Minnuo equipment is equipped with an adaptive pressure regulation system, which can real-time optimize pressure output according to drilling conditions, balancing efficiency and energy saving.

III. Impact of Environmental Factors on Operation and Optimization Requirements

The operational stability of the membrane nitrogen generator is highly dependent on environmental conditions. Especially since oil drilling is mostly carried out in the field or offshore, the following factors need to be focused on:

- Temperature Impact and Control Standards

- Optimal operating temperature: 20-30℃; Allowable range: 2-40℃.

- Hazards of low temperature (<2℃): Water vapor in compressed air is prone to freezing, blocking pipelines and valves, while reducing the separation efficiency of the membrane module, leading to a sudden drop in purity.

- Hazards of high temperature (>40℃): The decrease in hot air density results in reduced gas production, increased motor overload energy consumption, accelerated aging of membrane fibers, and even triggering equipment shutdown protection.

- Optimization plan: Equip pipeline heat tracing devices for low-temperature environments, and install industrial air conditioners or forced ventilation systems for high-temperature scenarios to ensure the temperature is stabilized within the optimal range.

- Humidity and Purity Requirements

- Ambient humidity: Relative humidity ≤ 80%, and the intake dew point needs to be controlled below -40℃.

- Hazards of high humidity: Moisture can irreversibly damage membrane fibers and adsorbent materials, leading to permanent degradation of purity, as well as causing pipeline corrosion and gas path pollution.

- Dust control: Avoid installation in dusty and corrosive gas environments; dust will block filters and increase equipment pressure drop.

- Optimization plan: For the rainy season in southern China or high-humidity offshore environments, configure a combined refrigerated + adsorptive dryer and industrial dehumidifier; reserve maintenance channels around the equipment and regularly clean filter elements.

- Basic Requirements for Installation Environment

- Priority should be given to indoor installation; for outdoor installation, a rain shelter must be built to avoid direct sunlight and rain erosion.

- The installation foundation must be stable and firm to reduce the damage of vibration to the membrane module and valves.

- Keep the site clean and ventilated to dissipate heat generated by equipment operation and avoid local overheating.

IV. Engineer’s Perspective: Professional Suggestions for Efficient Operation of Membrane Nitrogen Generator

Combined with the years of experience of the Minnuo engineer team in serving oil drilling equipment, optimization suggestions are given from three dimensions: operation, maintenance, and adaptation:

- Operation Level: Strictly follow the three-step startup process of “preheating – trial operation – loading” to avoid no-load or overload operation of the equipment; real-time adjust purity and pressure parameters according to drilling conditions (such as formation changes and drilling depth), and prohibit long-term operation deviating from rated conditions.

- Maintenance Level: Establish a mechanism of “daily inspection – regular maintenance – quarterly calibration” — check filter pressure difference and dew point indicators daily, clean the equipment’s heat dissipation channels weekly, replace filter elements monthly, and calibrate the purity analyzer through third-party testing every quarter to ensure stable equipment performance.

- Adaptation Level: For offshore drilling, select equipment with modular and salt spray corrosion-resistant design (such as Minnuo using 316L stainless steel material and marine-grade coating); for deep drilling, configure high-power membrane modules and energy-saving motors to reduce energy consumption under high-pressure conditions.

V. Industry Future Planning and Minnuo’s Technology Layout

With the expansion of oil drilling to deep, deep-sea, and high-difficulty formations, the membrane nitrogen generator industry will show three major development trends:

- Technology Upgrade Direction: Develop composite membrane materials with higher temperature resistance (>50℃) and pressure resistance (>1.5MPa) to improve adaptability to extreme environments; integrate AI intelligent monitoring systems to realize working condition prediction, fault early warning, and automatic optimization adjustment.

- Energy Conservation and Environmental Protection Trends: Promote low-energy-consuming membrane separation technology, aiming to reduce specific energy consumption to below 0.3kW·h/m³, saving more than 30% energy compared with traditional equipment; develop recycling systems to reduce nitrogen emission losses.

- Customization and Modularization: Provide customized solutions for different drilling scenarios (onshore, offshore, deep wells), and adopt modular design to facilitate transportation, hoisting, and maintenance, meeting the flexibility requirements of field operations.

Following the industry trends, Minnuo has laid out three core technologies: first, independently developed corrosion-resistant composite membrane modules, with pollution resistance and service life 20% higher than the industry average; second, AI intelligent control system, which can real-time monitor equipment operation data through the cloud to realize remote fault diagnosis; third, modular skid-mounted design, with high equipment integration, adapting to the complex installation environment of offshore platforms and field drilling.

VI. Minnuo Full-Cycle Service Support: Professional Team and After-Sales Support

To ensure the continuous and stable operation of oil drilling, Minnuo has established a full-cycle service system of “technical consultation – installation and commissioning – operation and maintenance support – lifelong service”:

- Senior Engineer Team: Core technical personnel all have more than 10 years of experience in R&D and service of nitrogen generation equipment for oil drilling, and have participated in equipment adaptation and commissioning of many large projects such as CNOOC and Sinopec, capable of providing customized technical solutions.

- Comprehensive Service Process

- Pre-sales: Conduct on-site investigation of working conditions, issue targeted equipment selection reports and installation plans.

- In-sales: Provide free installation and commissioning, and operator training to ensure rapid commissioning of the equipment.

- After-sales: Establish a 48-hour emergency response mechanism, set up more than 20 service outlets nationwide, and achieve 24-hour on-site maintenance in coastal areas; conduct regular on-site inspections, provide free calibration of testing instruments, and timely replace aging components.

- Equipment Testing and Guarantee Capabilities: Equipped with a professional testing team and third-party certification laboratory, each piece of equipment undergoes a 72-hour continuous operation test before leaving the factory to ensure that indicators such as purity and pressure meet API 6D standards; provide lifelong equipment maintenance services, and free replacement of core components during the warranty period, reducing customer operation and maintenance costs.

sales2:+86 17506119168

sales2:+86 17506119168