Walk through any successful plant, and you’ll find a key difference in how they view equipment. They don’t just see utilities; they see levers for growth. While most businesses record their nitrogen supply as a line-item expense on the P&L sheet, industry leaders have made a critical mindset shift: They’ve stopped being nitrogen buyers and started being nitrogen producers.

This isn’t just semantics. It’s the difference between constantly trying to cut a cost and strategically investing in a capability that makes you money. An on-site nitrogen generator isn’t just a replacement for delivered gas—it’s a strategic asset that pays you back daily by unlocking new levels of quality, efficiency, and revenue.

This guide is for forward-thinking managers and owners ready to calculate the true return on investment—one that goes far beyond the monthly gas bill.

The Hidden Profit Killer: Your Current Nitrogen Supply

Before we talk about gains, we must diagnose the silent profit leaks in the status quo. Relying on delivered nitrogen isn’t just a cost; it’s a cap on your potential.

- The Quality Tax: Inconsistent purity from delivered sources can lead to micro-defects. In laser cutting, this means a slightly duller finish that requires secondary polishing. In food packaging, it can mean a 10% shorter shelf life. You’re leaving money on the table by accepting “good enough” quality.

- The Innovation Tax: How many times has a process improvement or a new product trial been delayed because you were waiting on a gas delivery? The inability to experiment freely and rapidly stifles innovation and lets more agile competitors seize market opportunities.

- The Inflexibility Tax: Your production schedule is held hostage by your supplier’s delivery schedule. You can’t easily ramp up for a surprise large order without incurring expensive emergency delivery fees. This operational rigidity has a real, albeit hidden, cost.

The Profit Center Blueprint: How On-Site Generation Pays You Back

Switching to on-site generation flips the script. It transforms nitrogen from a variable, unpredictable expense into a fixed, controllable utility, unleashing multiple profit streams.

1. Drive Premium Pricing with Unmatched Quality

Consistent, high-purity nitrogen is a direct input to a superior product.

- Case in Point: Metal Fabrication. A shop using on-site nitrogen for laser cutting achieves a “clean-cut” surface so perfect it requires no post-processing. This allows them to bid on and win high-margin contracts in the aerospace and medical industries, commanding a 15-20% price premium over competitors stuck with oxidative cutting.

- The Bottom Line: When your product is objectively better, you don’t compete on price—you win on value.

2. Slash the Cost of Non-Conformance

Rework and scrap—the direct losses from quality failures—are a direct assault on your profit margin. On-site nitrogen acts as a powerful quality control tool.

- Case in Point: Electronics Manufacturing. In soldering processes, even trace oxygen can lead to weak joints. By guaranteeing an inert atmosphere with on-site N₂, a manufacturer can reduce their defect rate from 2% to 0.5%. For a $10 million product line, that saves $150,000 annually in scrap and rework costs alone.

- The Bottom Line: Prevention is always cheaper than correction.

3. Unlock New Markets with Reliable, Low-Volume Production

For small to mid-sized businesses, the ability to guarantee quality can be the key to expansion.

- Case in Point: A Regional Snack Food Producer. A local chip company invested in a small-scale nitrogen generator to flush their packaging. This extended their product’s crispness and shelf life reliably, allowing them to secure contracts with regional supermarket chains that were previously out of reach due to spoilage concerns. The relatively small investment in a generator opened up a significantly larger revenue stream.

- The Bottom Line: Control over your core processes allows you to scale your business predictably.

The New ROI Calculation: It’s Not Just About Gas Savings

The old ROI model only compared the cost of the generator to the cost of delivered gas. That’s an incomplete picture. The new, comprehensive ROI must include:

| ROI Component | Traditional View | Profit-Center View |

| Direct Savings | Liquid Nitrogen / Cylinder Costs | ✓ Included |

| Operational Gains | (Often Ignored) | Energy Efficiency, Lower Maintenance |

| Strategic Gains | (Never Included) | Premium Pricing, Scrap Reduction, New Revenue |

The Real Question: Is a machine with a 3-year payback based on gas savings alone a good investment? What if its strategic gains make the effective payback under 12 months?

Is Your Business Ready for This Upgrade?

You are an ideal candidate to treat nitrogen as a profit center if you answer “yes” to any of the following:

- Is product quality and consistency your key differentiator?

- Are you losing bids because of minor quality issues your competitors have solved?

- Does your production or R&D ever get delayed waiting for supplies?

- Are you looking to enter a higher-margin, more demanding market?

- Are you a growing business where reliable, high-quality production is key to your expansion plans?

Conclusion: Stop Buying Nitrogen, Start Manufacturing Value

The conversation needs to evolve from “How much does the equipment cost?” to “How much value can the equipment create?“

Continuing with delivered nitrogen means accepting hidden taxes on your quality, flexibility, and growth potential. Investing in an on-site generator isn’t an expense—it’s a strategic decision to take control of your production destiny and convert a utility into an engine for profit.

Ready to Calculate Your True ROI?

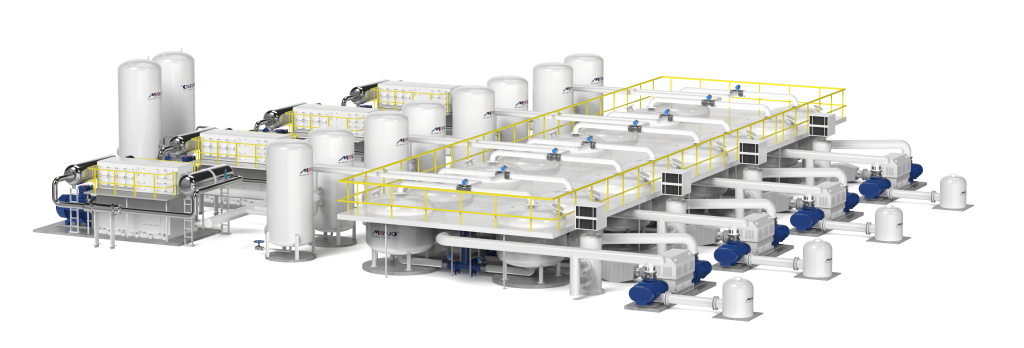

Stop evaluating costs. Start projecting gains. Contact MINNUO for a free, comprehensive Profit Potential Assessment. We’ll analyze your current operations and model how an on-site nitrogen generator can improve your margins, enhance your product, and grow your business.

sales2:+86 17506119168

sales2:+86 17506119168