Introduction

As a high-energy-consumption and high-precision basic industrial field, the combustion efficiency and temperature stability of the core process—glass melting furnace—directly determine the product quality and production cost of glass production. Oxy-fuel combustion technology, by increasing the oxygen concentration in the combustion-supporting gas, can significantly raise the flame temperature, reduce fuel consumption, and decrease pollutant emissions, having become a key direction for the upgrading of the modern glass industry. Vacuum Pressure Swing Adsorption (VPSA) oxygen generators, with their technical advantages of low energy consumption, high stability, and flexible adaptability, have gradually replaced traditional bottled oxygen and cryogenic oxygen production, emerging as the preferred oxygen supply solution for the oxy-fuel combustion systems of glass enterprises. Based on Jiangsu Minnuo Group’s years of R&D experience and engineering practice in VPSA technology, this paper deeply analyzes the application value of VPSA oxygen generators in the glass production industry.

Oxygen Demand in the Glass Production Industry and Limitations of Traditional Solutions

(I) Oxygen Usage Characteristics of Core Processes

The melting stage of glass production requires maintaining a high-temperature environment above 1500℃ to fully melt and homogenize raw materials such as quartz sand and soda ash. By introducing high-concentration oxygen into the combustion system of the melting furnace, oxy-fuel combustion technology can achieve three core goals: first, increasing the flame temperature by 50-100℃, accelerating the raw material melting rate, and shortening the melting cycle; second, reducing flue gas emissions and minimizing waste heat loss; third, optimizing the convection state of the glass melt, and improving the light transmittance and flatness of the finished product. Depending on the type of glass, float glass production lines typically require an oxygen purity of 90%-94%, a daily oxygen consumption of thousands of cubic meters, and 24/7 continuous and stable supply, with the oxygen concentration fluctuation controlled within ±1%.

(II) Bottlenecks of Traditional Oxygen Supply Solutions

Previously, glass enterprises mainly adopted two oxygen supply solutions: bottled oxygen and cryogenic oxygen production. Although bottled oxygen offers flexible deployment, it has obvious shortcomings: the limited capacity of a single bottle leads to frequent bottle replacements, which may easily cause supply interruptions. Additionally, the transportation and storage costs are high—for enterprises with a daily oxygen consumption of over 500Nm³, the annual procurement cost is more than 30% higher than the investment in oxygen production equipment. While cryogenic oxygen production can meet large-scale oxygen demand, the equipment occupies a large area (2.5 times that of VPSA equipment with the same capacity), has a long start-up time of 4-6 hours, and cannot adapt to the dynamic load adjustment of glass production lines. Moreover, the initial investment and maintenance costs are extremely high, making it unaffordable for small and medium-sized enterprises. Furthermore, the oxygen purity of cryogenic oxygen production usually exceeds 99.6%, which is far higher than the demand of glass production, resulting in energy waste.

Technical Advantages of VPSA Oxygen Generators and Adaptability to the Glass Industry

(I) Core Technical Principles and Performance Parameters

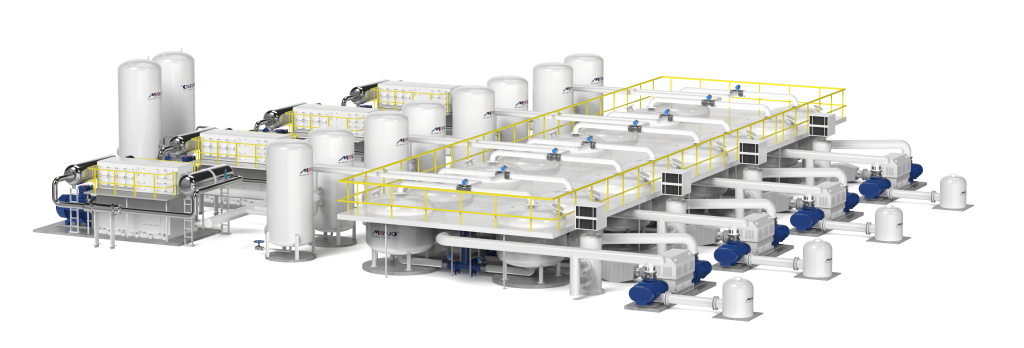

VPSA oxygen generators realize oxygen separation through a cyclic process of atmospheric pressure adsorption and vacuum desorption based on the selective adsorption characteristics of molecular sieves: after being compressed and purified, air enters the adsorption tower, where nitrogen is preferentially adsorbed by the molecular sieve, and oxygen is output as product gas; when the molecular sieve reaches adsorption saturation, the pressure inside the tower is reduced to a vacuum state by a vacuum pump to achieve molecular sieve regeneration. The VPSA oxygen generator developed by Jiangsu Minnuo Group adopts a twin-tower alternating adsorption process, combined with an independently developed intelligent variable load control system, achieving the following key performances: the oxygen purity is stably maintained at 90%-94%, accurately matching the requirements of glass melting furnaces; the oxygen production capacity of a single unit ranges from 500 to 7500Nm³/h, supporting parallel expansion of multiple units; the power consumption per unit oxygen production is as low as 0.38-0.42kWh/Nm³, saving more than 40% energy compared with the cryogenic method; the equipment start-up time is only 30 minutes, and the load adjustment response speed is less than 10 minutes.

(II) Adaptability Advantages for the Glass Industry

- Energy Efficiency and Cost Advantages: Glass enterprises can achieve significant cost savings by adopting VPSA oxygen generators. Taking a float glass production line with a daily oxygen consumption of 3000Nm³ as an example, the annual electricity cost of using Minnuo’s VPSA-3000 series equipment is about 450,000 yuan, saving more than 2 million yuan annually compared with bottled oxygen, and the equipment investment can be recovered within 1.5-2 years. Meanwhile, through oxy-fuel combustion technology, the fuel utilization rate is increased by 20%, further reducing the comprehensive energy consumption.

- Space and Deployment Flexibility: VPSA oxygen generators adopt a modular design, occupying only 40% of the area of cryogenic equipment with the same capacity. A glass enterprise deployed 3 sets of VPSA-1000 equipment, occupying only 30 square meters of space, saving 60% of the space compared with the traditional scheme. Moreover, parallel connection can realize flexible capacity expansion, and the installation and commissioning cycle is shortened to less than 7 days.

- Operational Stability Guarantee: The core components of the equipment adopt internationally renowned brands, such as Siemens motors from Germany and SMC pneumatic components from Japan. Combined with Minnuo’s patented adsorption tower structure (Patent No.: ZL 2024 2 2422801.9), the equipment’s operational stability reaches 99.5%, and the mean time between failures (MTBF) exceeds 8000 hours. The intelligent control system can real-time monitor more than 200 parameters, issue maintenance warnings 30 days in advance, and shorten the average time to repair (MTTR) to 4 hours.

- Environmental Protection and Compliance Adaptability: The combination of oxy-fuel combustion and VPSA oxygen production can reduce the carbon dioxide emissions of glass melting furnaces by 18% and sulfur dioxide emissions by 30%, helping enterprises meet the “dual carbon” goals and environmental protection regulatory requirements. The equipment operation noise is below 75 decibels, complying with the noise standards for industrial plants.

Typical Application Scenarios of VPSA Oxygen Generators in Glass Production

(I) Oxy-fuel Combustion System of Float Glass Melting Furnaces

Float glass production has extremely high requirements for temperature uniformity. Traditional air combustion easily leads to a temperature difference of more than 50℃ across the cross-section of the melting furnace, affecting glass flatness. After a large-scale float glass enterprise adopted Minnuo’s VPSA-5000 oxygen generation system, the oxygen concentration was stably controlled at 93%±0.5%, and oxygen was accurately delivered to 16 pairs of burners through pipelines. The project operation data shows that the temperature fluctuation of the melting furnace is reduced by 50%, the uniformity of the glass melt is improved by 15%, and the product qualification rate is increased from 91% to 99.2%; the natural gas consumption is reduced by 18%, the annual carbon dioxide emissions are reduced by 12,000 tons, and the annual comprehensive benefit exceeds 5 million yuan.

(II) Intensification of Special Glass Melting Processes

Special glasses such as photovoltaic glass and pharmaceutical glass have strict requirements for the melting purity and fining effect of raw materials. A photovoltaic glass enterprise introduced the combined technology of VPSA oxygen production and oxy-fuel fining, and introduced oxygen with a purity of 92% to the surface of the glass melt in the later stage of melting to accelerate the escape of bubbles. After implementation, the internal bubble defects of the glass are reduced by 70%, the light transmittance is increased by 2 percentage points, meeting the high light transmittance requirements of photovoltaic modules; at the same time, the melting cycle is shortened by 12%, and the production capacity is significantly improved.

(III) Auxiliary Processes in Glass Deep Processing

In deep processing links such as glass coating and annealing, VPSA oxygen generators can provide a stable oxygen source for oxidation reactions and atmosphere protection. A glass deep processing enterprise adopted Minnuo’s skid-mounted VPSA-500 equipment to provide oxygen with a purity of 90% for the coating production line. Combined with an intelligent flow control system, it realizes precise adjustment of oxygen consumption (50-500Nm³/h) for different coating processes. The modular design of the equipment allows it to be directly deployed in the workshop, saving 80% of the storage space compared with bottled oxygen, and completely solving the problem of coating defects caused by bottle replacement, increasing the product yield by 8%.

Key Points for Selection, Operation and Maintenance of VPSA Oxygen Generators

(I) Scientific Selection Method

Glass enterprises need to comprehensively select equipment based on production scale, process requirements, and site conditions: for small and medium-sized production lines with a daily oxygen consumption of 500-3000Nm³, a single skid-mounted VPSA equipment (such as Minnuo’s VPSA-1000 series) can be selected for its advantage of rapid deployment; for large-scale production lines with a daily oxygen consumption exceeding 3000Nm³, a parallel scheme of multiple equipment is recommended—for example, 4 sets of VPSA-7500 equipment can form an oxygen generation station with a capacity of 30,000Nm³/h, and a backup unit should be configured to ensure continuous gas supply. During selection, key attention should be paid to the oxygen purity adjustment range, the equipment’s operating temperature adaptability (recommended -30℃ to 50℃), and energy consumption indicators. Priority should be given to products that have passed ISO9001 certification and comply with the GB/T 3863-2008 standard.

(II) Operation and Maintenance Management Strategies

- Daily Monitoring: Real-time monitor key parameters such as oxygen purity, pressure, and molecular sieve temperature through the intelligent control system to ensure that the oxygen purity fluctuation does not exceed ±1% and the adsorption tower pressure is stable within the set range.

- Regular Maintenance: Replace the air filter element every 6 months and the molecular sieve every 5-8 years in accordance with the equipment manual. Minnuo’s VPSA equipment is equipped with a remote operation and maintenance system, enabling remote support for fault diagnosis and parameter optimization.

- Emergency Guarantee: Formulate equipment failure emergency plans and configure oxygen buffer tanks with a capacity of 2-4 hours to ensure the normal operation of the production line during maintenance. At the same time, regularly conduct equipment start-stop and load adjustment drills to improve the emergency handling capabilities of operators.

Industry Application Prospects and Technical Upgrade Directions

With the advancement of the “dual carbon” goals and the intelligent upgrading of the glass industry, the application prospects of VPSA oxygen generators will continue to expand. Future technical upgrades will focus on three directions: first, energy efficiency optimization—through the R&D of new molecular sieve materials and process improvement, strive to reduce the power consumption per unit oxygen production to below 0.3kWh/Nm³; second, intelligent integration—develop an oxygen generation control platform linked with the MES system of glass production lines to realize dynamic matching between oxygen supply and production load; third, adaptation to special scenarios—optimize equipment structure and adsorbent formula for extreme environments such as high temperature and high altitude, further expanding the application scope.

As a deep cultivator in the field of PSA/VPSA technology, Jiangsu Minnuo Group has provided customized oxygen generation solutions for more than 30 glass enterprises nationwide, with the equipment operational stability and customer satisfaction both reaching over 98%. In the future, it will continue to be driven by technological innovation to provide higher-quality oxygen supply equipment and services for the green and efficient production of the glass industry.

sales2:+86 17506119168

sales2:+86 17506119168