You invested in a PSA oxygen generator for a critical reason: a guaranteed, stable supply of high-purity oxygen to power your process, from wastewater ozone generation and laser cutting to medical gas supply and metal fabrication. The spec sheet promised 95% purity, and for a while, it delivered.

But now, something’s wrong. Your ozone production has dropped. Your combustion efficiency is down. Your product quality is inconsistent. You’re seeing purity readings below specification, or worse—the numbers are jumping around erratically.

This isn’t just an inconvenience; it’s a direct threat to your productivity and bottom line. This guide is for anyone asking, “Why is my machine not living up to its promise?” We’ll act as your diagnostic partner, uncovering the root causes of low or unstable oxygen purity and providing a clear roadmap to restore your generator’s performance.

Before You Start: Gather Your Diagnostic Tools

Accurate troubleshooting requires the right tools. Before you begin, gather the following for an efficient diagnosis:

- Calibrated oxygen analyzer (or calibration gas for your existing analyzer)

- Pressure gauge (to verify inlet air pressure)

- Flow meter (to measure output flow rates)

- Flashlight (for safely inspecting valves and internal components)

The 5 Culprits Behind Failing Oxygen Purity

Once you’ve confirmed the reading is accurate, investigate these five areas, starting with the most common.

Culprit #1: Compromised Air Supply (The Foundation of Purity)

Your oxygen generator is only as good as the air you feed it.

- Problem: Low Inlet Air Pressure. The PSA process requires a minimum pressure to function correctly. If your air compressor can’t maintain pressure, or if pre-filters are clogged, the adsorption towers won’t fill completely, leading to poor separation and low purity.

- Symptom: Purity drops consistently, especially during periods of high air demand elsewhere in the plant.

- Fix: Check and clean inlet air filters monthly. Ensure your air compressor is sized correctly and maintaining stable pressure (typically 85-115 PSI, check your manual).

Culprit #2: The Silent Killer: Molecular Sieve Degradation

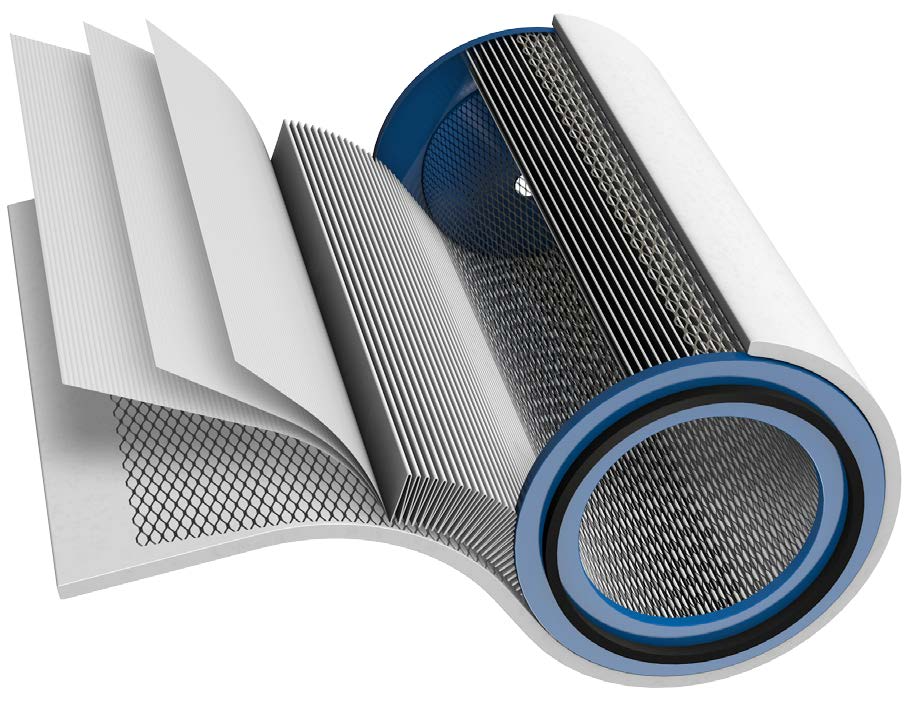

The molecular sieve is the heart of your generator, and it can wear out or be poisoned.

- Problem: Contamination or Aging. Oil vapor, water droplets, or hydrocarbon aerosols from your compressed air system can permanently poison the sieve, clogging its microscopic pores. Over years, normal mechanical fatigue from pressure cycling can also reduce its adsorption capacity.

- Symptom: A slow, steady, and irreversible decline in maximum achievable purity.

- Fix: Protect your sieve with high-efficiency coalescing filters and a refrigerant dryer. Signs of sieve poisoning include a sudden drop in purity after compressor maintenance (e.g., oil leak) or a persistent musty odor from the generator exhaust. If poisoning is severe, the sieve bed must be replaced.

Culprit #3: Valve Failure (The Most Common Mechanical Fault)

The precision of the PSA cycle depends on a set of pneumatic valves opening and closing millions of times.

- Problem: Leaking or Sticky Valves. A valve that doesn’t seal perfectly will allow air or oxygen to leak between the towers, disrupting the delicate pressure balance and contaminating the product stream.

- Symptom: Unstable, fluctuating purity is a classic sign of valve issues. You may also hear a hissing sound.

- Fix: Isolate and test each valve by temporarily disabling individual valves (per manufacturer guidelines) to observe purity changes. Rebuild or replace faulty valves with OEM parts to ensure a perfect seal.

Culprit #4: Control System & Sensor Drift

The controller is the brain that orchestrates the PSA cycle.

- Problem: Incorrect Cycle Timing or Faulty Sensors. If the controller’s timing for pressurization, depressurization, and purge is off, the sieve beds won’t regenerate properly. A faulty pressure transducer can also send false data, causing the brain to make bad decisions.

- Symptom: Erratic purity, often coupled with unusual system pressure readings.

- Fix: Verify cycle timing settings against factory specifications. Have a technician check sensor calibration.

Culprit #5: A Simple Mismatch: Demand Exceeds Supply

- Problem: Your oxygen demand is higher than your generator’s rated capacity. If you’re drawing more oxygen than the generator was designed for—whether for expanded production lines or new equipment additions—it simply won’t have time to produce high-purity gas. The flow rate is too high.

- Symptom: Purity is acceptable at low flow but drops significantly as you open the valve to higher flow rates.

- Fix: Check your actual oxygen consumption against the generator’s flow capacity at your desired purity. You may need to reduce demand or upgrade your system.

Your Step-by-Step Troubleshooting Plan

Follow this sequence to diagnose the issue efficiently:

- Test the Analyzer: Calibrate your oxygen analyzer. This is always step one.

- Check Inlet Pressure: Use your pressure gauge to verify stable, adequate air supply pressure at the generator inlet.

- Conduct a Flow Test: Use a flow meter to measure purity at different output flow rates. If purity drops as flow increases, you have a capacity issue (Culprit #5) or a restricted sieve bed (Culprit #2).

- Listen and Look: With the cover off (safely!), listen for the distinct “hiss-tick” of the valves. A leaking valve often sounds different. Use a flashlight to inspect for obvious issues. Observe the system pressures on the controller versus local gauges.

- Call a Professional: If the above steps don’t pinpoint the issue, it’s time for an expert to dive into valve diagnostics and controller logic.

Frequently Asked Questions

Q1: Can I just adjust the oxygen purity setting on my controller to fix low purity?

A1: No. The purity setting is a target, not a control. If the system can’t reach that target, it means a physical component (sieve, valve, compressor) is failing. “Adjusting” the setting is like covering up a check engine light without fixing the engine.

Q2: How often should the molecular sieve be replaced?

A2: With clean, dry, oil-free air, a sieve can last 5-10 years. With poor air quality, it can fail in under 2 years. There’s no fixed schedule; its lifespan is determined by your air quality and operating hours.

Q3: Our purity is fine most of the time, but it randomly drops for a few minutes. What gives?

A3: This is a classic sign of Culprit #3 (Valve Issues). A valve that occasionally sticks or doesn’t seal perfectly will cause short, sharp dips in purity.

Q4: Our oxygen purity dropped suddenly and we need to maintain production—what can we do temporarily?

A4: Reduce your oxygen flow rate to the minimum required for production (this buys the generator time to produce higher purity). Check and replace inlet air filters immediately. Ensure no other equipment is drawing excess compressed air (to stabilize inlet pressure). This is a temporary fix—you must diagnose the root cause (e.g., valve leak, sieve contamination) to avoid long-term issues.

Conclusion: Restore the Promise with Factory Expertise

Low or unstable oxygen purity is a symptom, not the disease. While this guide equips you to diagnose common issues, some problems require factory-level expertise to be resolved definitively.

As the original manufacturer, MINNUO offers unparalleled insight into your PSA generator’s design and performance. We provide detailed technical guidance and can help you implement the most effective repair or upgrade strategy, ensuring your solution is backed by the deepest understanding of the equipment.

Need Manufacturer-Grade Support?

When standard solutions fall short, it’s time to connect with the source.

Contact the MINNUO engineering teamfor specialized technical consultation and factory-approved repair recommendations. Get precise guidance tailored to your specific generator model and operational conditions to restore optimal performance.

sales2:+86 17506119168

sales2:+86 17506119168