In the field of metal processing, fiber laser cutting technology has become an indispensable core process in modern manufacturing due to its advantages of high precision, high speed, and low loss. The efficient and stable operation of this process is inseparable from the precise empowerment of high-purity oxygen—oxygen, as a key auxiliary gas in fiber laser cutting, undertakes the core roles of supporting combustion, blowing away molten slag, and improving cutting efficiency and section quality. Especially oxygen with 99.5% purity can maximize the avoidance of impurity interference in the cutting process, directly determining cutting precision, edge smoothness, and material utilization rate. As a key equipment for on-site production of high-purity oxygen, the performance of the oxygen generator is a core factor affecting enterprises’ production efficiency and cost control. Today, as a salesperson of Jiangsu Minnuo, I will take you to focus on the 99.5% purity oxygen generator dedicated to fiber laser cutting and reveal why Jiangsu Minnuo has become a trusted choice for numerous metal processing enterprises.

First, let’s clarify the core question: Why must fiber laser cutting use a 99.5% purity oxygen generator? And how to achieve stable gas production? From the perspective of process requirements, during fiber laser cutting, oxygen needs to undergo an oxidation reaction with metal materials to release a large amount of heat, assisting the laser in quickly melting the material while blowing away the molten slag generated during cutting. If the oxygen purity is insufficient (lower than 99.5%), impurities such as nitrogen and water vapor contained in it will lead to unstable cutting temperature, resulting in problems such as burrs, slag adhesion, and rough sections at the cut. This not only increases the cost of subsequent grinding processes but may also cause material scrapping; in contrast, 99.5% high-purity oxygen can ensure a sufficient and uniform oxidation reaction, making the cut smooth and flat, while improving cutting speed to meet the efficient cutting needs of various metal materials such as stainless steel and carbon steel.

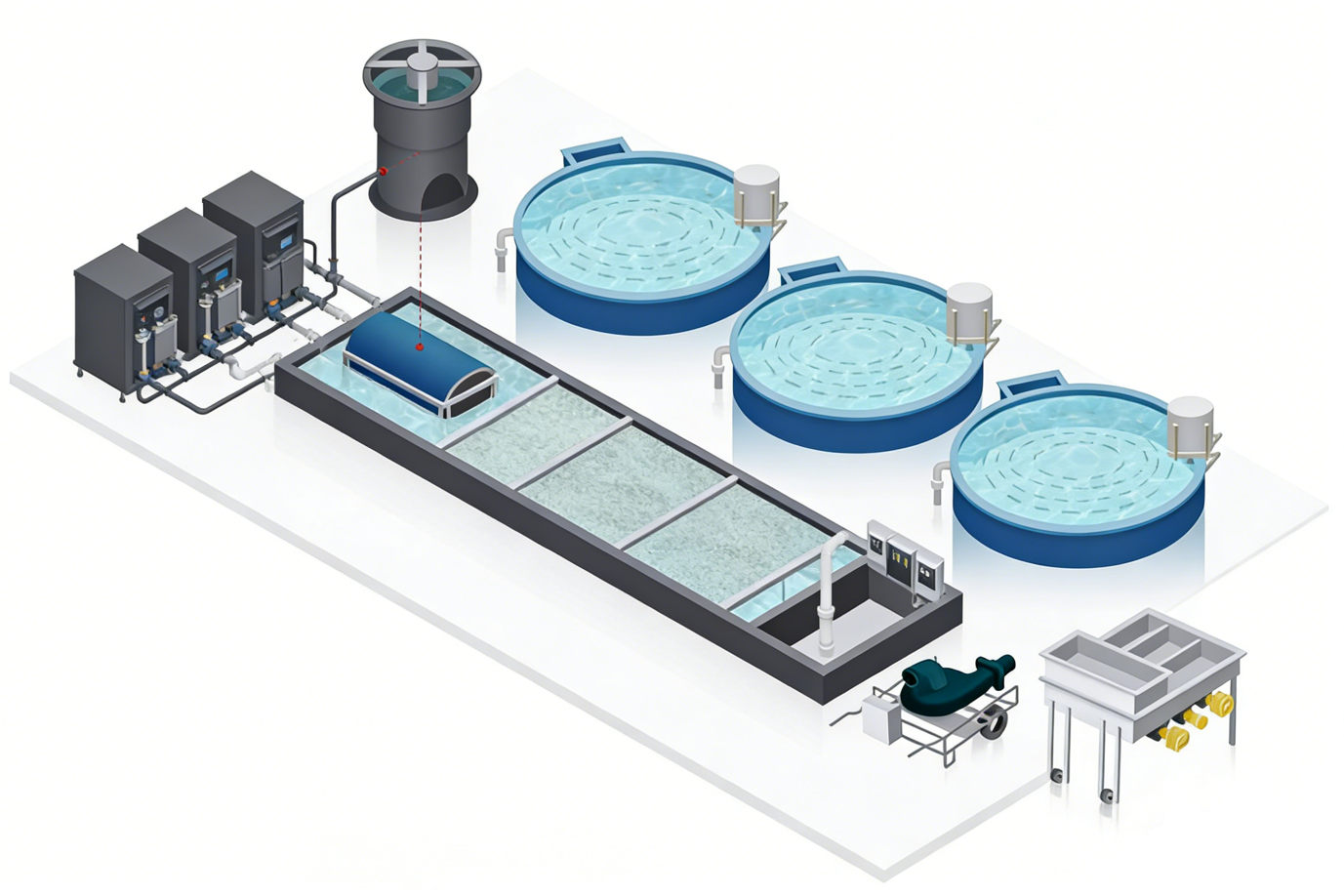

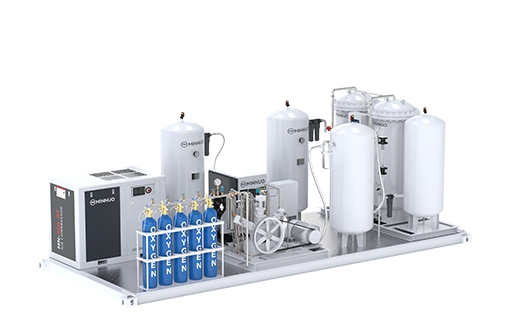

From the perspective of oxygen production principles, the mainstream oxygen production technology currently adapted to fiber laser cutting scenarios is Pressure Swing Adsorption (PSA), which is also the core technical path of Jiangsu Minnuo’s oxygen generators. This technology uses air as raw material and high-quality zeolite molecular sieve as adsorbent. Through an imported PLC control system to precisely regulate the operation of pneumatic valves, two adsorption towers alternately complete the processes of pressure adsorption and pressure reduction regeneration. Utilizing the difference in adsorption capacity of molecular sieves for nitrogen and oxygen molecules, efficient separation of oxygen and nitrogen is achieved. Pure oxygen with stable 99.5% purity can be produced within 15-30 minutes of startup, without additional waiting time. Compared with traditional cylinder oxygen supply and liquid nitrogen vaporization oxygen supply, PSA oxygen generators have significant advantages: no need for frequent procurement and transportation, avoiding safety hazards and transportation costs of high-pressure gas cylinders; continuous and stable gas production, not affected by external gas supply links; low operating energy consumption, which can greatly reduce enterprises’ long-term gas use costs, especially suitable for the 24/7 continuous operation working condition of fiber laser cutting machines.

Understanding the core requirements of fiber laser cutting for oxygen generators, enterprises need to focus on key dimensions during selection to avoid falling into selection misunderstandings: First, purity stability. This is a core indicator. It is necessary to ensure that the equipment can stably output oxygen with 99.5% purity for a long time, and the fluctuation range should be controlled within ±0.2%; otherwise, the cutting quality will be directly affected. Second, gas production rate and flow matching degree. It is necessary to accurately match the oxygen production capacity (Nm³/h) according to the power of the fiber laser cutting machine (such as 1000W, 3000W, 6000W). It is recommended to reserve a 10%-20% redundancy to avoid insufficient production capacity during peak gas use. Third, equipment continuity and reliability. Fiber laser cutting is mostly continuous production, so the oxygen generator needs to support 24/7 uninterrupted operation and be equipped with a sound fault early warning mechanism. Fourth, energy consumption and operation and maintenance costs. Priority should be given to equipment with a low air-oxygen ratio and long service life of core components to reduce long-term operation and consumable replacement costs. Many enterprises only focus on the initial purchase price during selection, ignoring purity stability and energy consumption. In the later stage, they not only face cutting quality problems but also affect profits due to high gas use costs, which is not worth the loss. As a practitioner deeply engaged in the industrial gas equipment field for many years, I suggest that enterprises must combine their own laser cutting machine power, processing materials, and production capacity requirements to choose professional brands that can provide customized solutions.

This is also the core reason why Jiangsu Minnuo’s 99.5% purity oxygen generator is highly recognized by metal processing enterprises—we focus on the exclusive working conditions of fiber laser cutting, reject generalized equipment, and only aim to provide precisely adapted customized oxygen production solutions. Relying on the R&D and manufacturing capabilities certified by the ISO-9001 international quality management system, Jiangsu Minnuo’s core advantages in the field of dedicated oxygen generators for fiber laser cutting are reflected in three aspects: First, high-quality core components to ensure stable purity. We adopt imported high-efficiency zeolite molecular sieves (adapted to the precise separation needs of 99.5% purity), German original pneumatic valves, and high-precision flow meters. The molecular sieve is guaranteed for 10 years, and the main valves are guaranteed for 20 years, eliminating purity fluctuation problems from the source. Second, strong customized adaptation capabilities. According to the customer’s fiber laser cutting machine power (1000W-12000W), processing materials (carbon steel, stainless steel, etc.), and production capacity requirements, we can accurately design the oxygen production system with matching oxygen output, ensuring perfect matching of flow and pressure, while supporting parallel gas supply for multiple cutting machines. Third, high efficiency, energy saving, safety, and reliability. Compared with traditional cylinder oxygen supply, Minnuo’s PSA oxygen generator can help enterprises save 40%-200% of gas use costs. The system is equipped with a fully automatic PLC control system, which can display real-time data such as oxygen purity, flow, and pressure, and has functions of automatic fault alarm and emergency shutdown, supporting unattended operation. At the same time, it avoids the transportation and storage risks of high-pressure gas cylinders, ensuring production safety.

With precise customized solutions and reliable product quality, Jiangsu Minnuo’s 99.5% purity oxygen generator has been widely used in various fiber laser cutting application fields such as auto parts processing, engineering machinery manufacturing, and hardware product production. Thousands of sets of systems have been installed at home and abroad, accumulating rich industry cases. Whether it is the supporting of a single laser cutting machine in a small hardware factory or the centralized gas supply for multiple equipment in a large manufacturing enterprise, we can tailor the optimal oxygen production solution according to the customer’s specific production conditions, providing full-process one-on-one intimate services from equipment selection, on-site installation and commissioning to later operation and maintenance, ensuring the equipment is put into production quickly and operates stably.

For fiber laser cutting enterprises, choosing a 99.5% purity oxygen generator is not just purchasing a piece of equipment, but selecting a long-term partner that can ensure stable production and reduce costs. Jiangsu Minnuo has always adhered to the concept of “quality first, customer foremost”, using professional technology, reliable products, and perfect services to help enterprises achieve the core needs of “stable gas supply, efficient cutting, energy saving, and cost reduction”. If you are struggling with the selection of supporting oxygen generation equipment for your fiber laser cutting machine, or want to learn about targeted customized solutions, please feel free to contact us—Jiangsu Minnuo, let 99.5% high-purity oxygen accurately empower your laser cutting production!

sales2:+86 17506119168

sales2:+86 17506119168