I. The “Oxidation Dilemma” of High-Temperature Aluminum Products: Quality Crisis Under Invisible Loss

Aluminum and its alloys are widely used in key fields such as aerospace, building profiles, and electronic devices due to their lightweight, high strength, and excellent thermal and electrical conductivity. However, aluminum has extremely strong chemical activity (standard electrode potential of approximately -1.66V), and in high-temperature processing scenarios (such as smelting, extrusion, annealing, and welding), oxidation reactions accelerate exponentially. When the temperature exceeds 600℃, approaching aluminum’s melting point (660℃), the surface oxide film transforms from a dense protective state to a porous and loose structure, losing its protective capability.

The hazards caused by high-temperature oxidation directly impact production efficiency:

- Appearance Deterioration: Grayish-white, grayish-black oxide scales or “white rust” form on the surface, reducing the qualification rate of subsequent processing such as spraying and electroplating by more than 30%;

- Performance Attenuation: Thicker oxide films reduce thermal conductivity by 15%-20%, decrease mechanical strength, and lead to inaccurate dimensional precision of precision components;

- Cost Waste: Oxidation loss lowers material utilization rate, increases rework costs, and in severe cases, directly causes a sharp rise in scrap rate.

A coastal aluminum profile enterprise once suffered annual losses of millions of yuan due to high-temperature annealing oxidation, a common pain point in the industry.

II. Core Logic of Nitrogen Protection: Cutting the Oxidation Chain at the Source

The essence of metal oxidation is a chemical reaction between metal and oxygen under high-temperature conditions, and the inert nature of nitrogen (N₂) becomes the solution. Jiangsu Minnuo Nitrogen Generator extracts high-purity nitrogen from the air through PSA (Pressure Swing Adsorption) technology, constructing a three-fold protection system:

- Oxygen Isolation: Continuously injected nitrogen displaces air in the processing environment, reducing oxygen content to below 0.1% and cutting off the “reactant source” of oxidation reactions;

- Inert Protection: The N≡N triple bond of nitrogen molecules has extremely high bond energy, maintaining chemical stability even at high temperatures without reacting with the aluminum matrix or oxides, and without introducing new impurities;

- Atmosphere Regulation: Dry nitrogen can reduce environmental humidity, inhibit electrochemical breakdown of the oxide film, and slow down the kinetic process of oxidation reactions.

In key links of high-temperature aluminum product processing, the effect of nitrogen protection is immediate:

- During smelting/casting, nitrogen covers the surface of the aluminum liquid, preventing oxidation and gas absorption, reducing Al₂O₃ inclusions, and improving aluminum ingot purity;

- During extrusion/rolling, high-purity nitrogen forms a protective film, ensuring the profile surface is bright without oxidation spots;

- During annealing treatment, the nitrogen atmosphere avoids oxidative discoloration, optimizes the aluminum material structure, and improves subsequent processing performance.

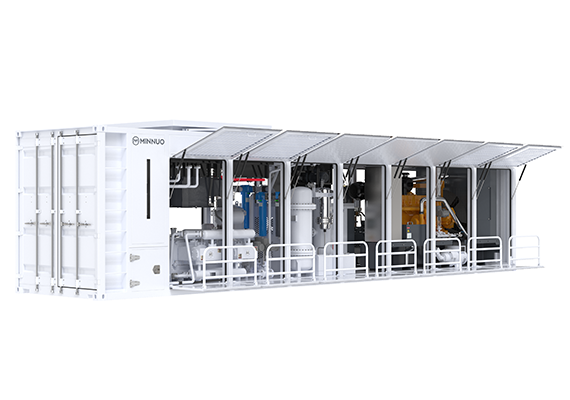

III. Jiangsu Minnuo Nitrogen Generator: A Tailor-Made Protection Tool for High-Temperature Aluminum Processing

Targeting the core demand for surface protection of high-temperature aluminum products, Jiangsu Minnuo Nitrogen Generator has become the preferred solution for enterprises through technological iteration and industry adaptability:

- Stable Output of High Purity: Nitrogen purity can reach 99.99%-99.999%, accurately matching the requirements of different high-temperature processes. Even under extreme working conditions above 600℃, it can effectively inhibit oxidation;

- Efficient and Energy-Saving Design: Adopting imported molecular sieves (service life up to 15 years), energy consumption is 20% lower than traditional equipment. It can reach the set purity within 5 minutes of startup, supporting on-demand start-stop to reduce invalid consumption;

- Intelligent and Precise Control: Equipped with an online oxygen content monitoring and closed-loop feedback system, it real-time adjusts nitrogen flow and purity, and automatically alarms for deviations in oxygen concentration to ensure comprehensive protection;

- Compact and Flexible Adaptability: The equipment has a compact structure, small footprint, and supports modular installation. It can be flexibly adjusted according to the production line layout, adapting to various processing equipment such as smelting furnaces, annealing furnaces, and extruders;

- Local Service Guarantee: As a local enterprise in Jiangsu, Minnuo has a rapidly responsive technical team, providing full-cycle services from scheme design, installation and commissioning to after-sales maintenance, solving enterprises’ worries.

IV. Case Witness: From Loss Control to Quality Upgrade

After introducing Jiangsu Minnuo Nitrogen Generator, a large aluminum profile enterprise achieved significant improvements in the 650℃ extrusion molding process:

- The oxidation scrap rate dropped from 8.7% to 1.2%, saving over 2 million yuan in material costs annually;

- The surface finish of profiles was upgraded by one level, the adhesion of subsequent spraying was enhanced, and the product qualification rate increased to 99.5%;

- On-demand nitrogen supply reduced waste, cutting annual energy consumption costs by 180,000 yuan.

In high-end application scenarios such as heat treatment of aerospace aluminum alloy components and electronic aluminum foil rolling, Jiangsu Minnuo Nitrogen Generator also helps enterprises pass stringent quality certifications and enhance core product competitiveness with its stable protection effect.

Conclusion: Taking Nitrogen as a Shield to Safeguard the Original Metal Luster

Anti-oxidation protection of high-temperature aluminum products is not only crucial for quality control but also the core support for enterprises to reduce costs, increase efficiency, and move towards high-end manufacturing. Jiangsu Minnuo Nitrogen Generator deeply explores industry needs, and with professional technology, stable performance, and attentive services, builds a comprehensive anti-oxidation barrier for aluminum processing enterprises, allowing every aluminum product to maintain its original luster through high-temperature tempering, and helping enterprises seize opportunities in the fierce market competition.

sales2:+86 17506119168

sales2:+86 17506119168