Oxygen production is critical in industries such as steel manufacturing, metal cutting, and chemical processing. Pressure swing adsorption (PSA) oxygen generators provide an efficient and economical solution by separating nitrogen from compressed air to extract oxygen, providing a reliable source of pure oxygen for a wide range of industries.

This article compares MINNUO and Youchigases PSA oxygen generators, focusing on their key features, performance, and economic advantages. By examining design robustness, energy efficiency, and maintenance needs, we aim to help industries choose the right oxygen generation system for their specific needs.

Are you wondering which brand offers the best value or performs better in challenging environments? This article will provide the answers, backed by data and real-world examples, to guide your decision in selecting the ideal PSA oxygen generator for your business.

Company Overview and Technological Background

MINNUO:

Company Profile:

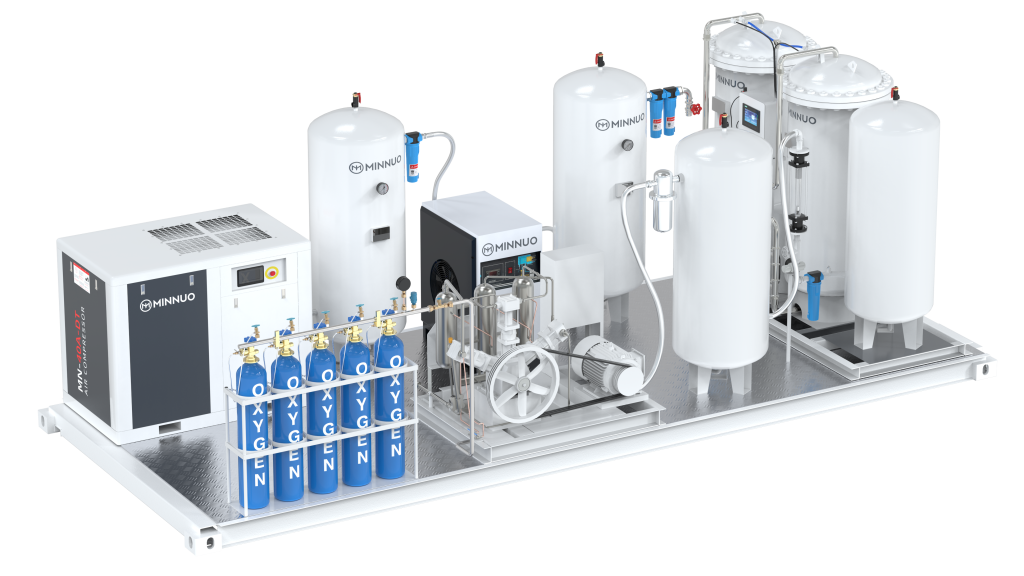

MINNUO specializes in high-performance, long-life PSA oxygen systems, serving a wide range of industries including steel manufacturing, healthcare, chemical production, and mining. With decades of experience and a commitment to excellence, MINNUO is renowned for providing cutting-edge technology and customized solutions tailored to the specific operational needs of each client.

Technology and Features:

MINNUO’s PSA (Pressure Swing Adsorption) technology is designed to achieve efficient and reliable production. These systems prioritize energy efficiency, low maintenance costs, and long-term stability, making them ideal for industries requiring a continuous supply of high-purity oxygen in harsh environments. MINNUO’s PSA systems utilize advanced filtration technology, corrosion-resistant materials, and intelligent automation technology to ensure stable, optimal oxygen output while minimizing downtime. The system also offers flexibility, allowing customers to adjust purity levels (ranging from 93% to 99.5%) and flow rates according to specific requirements(Range: 5–5,000 Nm³/h).

Key Achievements:

MINNUO holds ISO 9001, ISO 13485, and CE certifications, demonstrating compliance with global industry standards and regulations.

The brand is widely recognized for its customer-centric philosophy, offering detailed consulting, after-sales service, and ongoing technical support.

MINNUO systems have been deployed in over 30 countries and are highly regarded in high-demand sectors such as steel manufacturing, healthcare, and chemical processing.

MINNUO continuously innovates in product development, focusing on enhancing operational efficiency, reducing energy consumption, and optimizing the long-term performance of oxygen production systems.

Youchigases:

Company Profile:

Youchigases is a leading company in the PSA oxygen generator industry, widely recognized for providing economical, reliable, and adaptable systems for industrial applications.

Technology and Features:

Youchigases’ PSA systems prioritize cost-effectiveness and ease of installation. These systems are specifically designed for industries with medium to high oxygen demand, focusing on maintaining a stable supply at a reasonable cost. Youchigases’ systems offer flexible configurations, providing a range of models with different flow rates and purity levels. Compared to other systems, their PSA systems are typically designed to be simpler and install faster, making them an ideal choice for customers seeking cost-effective and quick solutions.

Key Achievements:

Expanding Global Influence: Youchigases holds a significant position in emerging markets, renowned for its rapid turnaround times and ability to meet urgent customer needs, delivering products with the shortest possible lead times.

Highly Adaptable: Its systems can be extensively customized to suit small-scale or short-term projects. They are particularly favored by businesses seeking low initial investment costs or those with less stringent industrial requirements.

MINNUO vs. Youchigases: Comprehensive Comparison Guide for Industrial PSA Oxygen Generators

Core Parameter Comparison

| Indicators | MINNUO | Youchigases | Advantageous party |

| Oxygen purity | 93-95% (customizable to 99.5%) | 90-93% (standard range) | MINNUO |

| Energy consumption (kW/Nm³ O₂) | ≤0.38 | ≤0.42 | ↓10.5% |

| Annual maintenance cost ratio | 3-5% of equipment value | 5-7% | ↓40% |

| Delivery cycle | 60-90 days (customized solution) | 30-45 days (standardized scheme) | Youchigases |

| Design life | 20+ years (key components guaranteed for 100,000 hours) | 15 years (70,000 hours warranty) | MINNUO |

Energy Efficiency and Cost Comparison: MINNUO vs. Youchigases

Energy Consumption

MINNUO:

MINNUO’s PSA oxygen generator is designed with advanced energy-saving algorithms to minimize energy consumption, especially during low-demand periods. The system automatically adjusts operating settings based on oxygen demand, optimizing energy usage and reducing unnecessary consumption. As a result, compared to traditional low-temperature oxygen production systems, MINNUO’s system reduces energy consumption by 15-20%, achieving extremely high efficiency, particularly suitable for industries requiring stable oxygen supply but with significant fluctuations in demand (e.g., steel manufacturing or welding).

By integrating automated control, real-time demand-based regulation, and low-energy components that optimize the oxygen production process, energy efficiency is enhanced. These features help significantly reduce long-term operational costs.

Key advantages:

15-20% reduction in energy consumption compared to low-temperature systems.

Intelligent algorithms optimize performance and reduce energy use during periods of low demand.

Long-term energy savings lower overall operational costs, ensuring a higher return on investment (ROI).

Youchigases:

Youchigases’ PSA oxygen generators are energy-efficient and highly effective, but due to suboptimal design, they tend to consume more energy during peak load operation. The system may not be able to dynamically adjust to demand fluctuations efficiently, resulting in higher energy consumption during peak usage periods. Additionally, Youchigases’ system may lack equivalent energy-saving algorithms to automatically fine-tune operations.

Key Limitations:

High energy consumption during peak demand periods, leading to increased utility costs.

Low design optimization, resulting in limited energy savings during low-demand periods.

Long-term operational costs may be higher due to low energy usage efficiency.

Operating Costs

MINNUO:

The MINNUO PSA oxygen generator features automated functionality that minimizes the need for frequent manual intervention, resulting in low maintenance costs. The system’s self-monitoring capabilities and real-time adjustment features help reduce the incidence of malfunctions and maintenance frequency. Over the long term, these low maintenance and operating costs can yield significant cost savings for industries reliant on continuous oxygen supply, such as chemical plants or medical oxygen systems.

Key Advantages:

Low maintenance costs due to automatic monitoring and adjustment, minimizing downtime.

Reduced maintenance frequency, lowering labor and parts replacement costs.

Long-term cost reductions make MINNUO an economical choice for continuous operations.

Youchigases:

Youchigases PSA generators have slightly lower initial purchase costs but higher long-term operational expenses. This is due to their more frequent maintenance requirements and higher energy consumption.

Key Limitations:

Higher long-term operational costs due to increased maintenance and more frequent part replacements.

Higher energy consumption increases annual energy costs, offsetting the initial savings from the equipment purchase price.

Calculation Example:

For an industrial facility consuming 1,000 Nm³ of oxygen daily:

MINNUO:

Estimated annual energy consumption: 15,000 kWh

Total operational costs (including energy, parts, and labor): $10,000 annually

Youchigases:

Estimated annual energy consumption: 18,000 kWh

Total operating costs (including energy, parts, and labor): $12,500 per year

Return on Investment (ROI) Model

| Indicators | MINNUO | Youchigases | Financial impact |

| Initial investment in equipment | $250,696 | $208,913 | +$41,782 |

| Annual operating costs | $46,016 | $54,303 | ↓$8,286 |

| Payback period | 2.7 years | 3.8 years | Payback period reduced by 1.1 years |

| 10-year net present value (NPV) | $+172,701 | $+94,707 | +82% |

Key findings: Although MINNUO is 20% more expensive, it surpassed its competitors in sales in the third year.

Performance under harsh industrial conditions: MINNUO vs Youchigases

Temperature and humidity tolerance

MINNUO:

MINNUO’s PSA oxygen generator is designed to operate reliably in a variety of extreme environmental conditions, including temperatures ranging from -25°C to 55°C and high humidity environments. This versatility is achieved through an integrated advanced cooling system that regulates internal temperature and prevents overheating during high-demand operation. In industries where environmental conditions frequently exceed normal operating thresholds, such as steel production or chemical processing, the MINNUO system maintains stable performance, ensuring uninterrupted oxygen production.

Key Features:

Advanced cooling technology: Prevents overheating during high-temperature operations.

Wide temperature range: Reliably operates within a temperature range of -25°C to 55°C.

Humidity resistance: Performs well even in high-humidity environments, preventing corrosion.

Youchigases:

The Youchigases system is designed for standard industrial environments, but may struggle to cope with extreme temperature fluctuations or high humidity conditions without additional cooling infrastructure. For industries operating in high ambient temperature zones (e.g., glass manufacturing or metal forging), these generators may require additional cooling solutions to maintain optimal performance, resulting in higher operational costs.

Main limitations:

Additional cooling solutions are required in extreme environments.

Performance may degrade in extreme temperature fluctuations or high humidity without additional cooling infrastructure.

Extreme environment parameter comparison (based on IEC 60068 international environmental testing standards)

| Environmental challenges | MINNUO tolerance limits | Operating temperature range | Gap multiple |

| Temperature range | -25°C to 55°C (with active temperature control) | -10°C to 45°C (passive cooling) | 1.8x |

| Humidity tolerance | 100% RH continuous operation | 85% RH requires derating | →Failure threshold ↑18% |

| Dust concentration | 500 mg/m³ (no pressurization protection required) | 200 mg/m³ (requires additional pre-filtration) | 2.5x |

| Chemical corrosion (SO₂) | 50 ppm | 15 ppm | 3.3x |

| Altitude | 4500 meters (with power compensation) | 2500 meters | 1.8x |

Dust-proof and chemical corrosion-resistant

MINNUO:

One of its most notable advantages is its exceptional dust-proof and chemical resistance, making it an ideal choice for harsh industrial environments such as mining, cement production, and chemical manufacturing. These systems are equipped with high-efficiency filtration systems and corrosion-resistant coatings to prevent the destructive effects of dust, chemicals, and other particulates.

For example, in a cement plant where dust concentrations can reach dangerous levels, MINNUO’s generators are equipped with filtration systems capable of withstanding dust levels as high as 500 milligrams per cubic meter without compromising system performance. Compared to systems prone to clogging or corrosion, this translates to longer service life and lower maintenance costs.

Key advantages:

High-efficiency filtration prevents dust and particles in the air.

Corrosion-resistant coatings enhance durability in chemically corrosive environments.

Stable performance even in dust-intensive industrial sectors such as cement manufacturing and mining.

Youchigases:

Youchigases PSA generators are designed for handling light to moderate dust levels,

but in environments with higher dust or chemical concentrations, more frequent maintenance and filter replacements may be required. Their dust resistance is lower, with a maximum handling capacity of 200 mg/m³, beyond which performance degrades. Industries like cement production or mining may need to take additional measures to ensure these generators are properly maintained and filtered, which could increase long-term operational costs.

Main limitations:

Low dust tolerance: can only handle dust up to 200 mg/m³, requiring more frequent maintenance.

More frequent replacement of filters and parts in harsh environments.

Scene parameters: dust concentration 380 mg/m³ · contains metal particles · annual operation 6,500 hours

| MINNUO | Youchigases | |

| Filter cartridge life | 18 months | 4 months |

| Replacement cost | $1114/time | $905/session |

| Total cost over ten years | $6685 | $27,158 |

| Downtime losses | 0 (online replacement) | 32 hours/year (equivalent to $35,654) |

Flexibility and customization for specific needs: MINNUO and Youchigases

Customization options

MINNUO:

MINNUO stands out for its highly flexible system configuration, offering custom purity levels ranging from 93% to 99.5% and flow rates up to 5000 Nm³/h. This extensive product range enables the MINNUO system to meet the needs of various industries, from healthcare (high-purity oxygen requirements) to steel manufacturing (where stable oxygen flow is critical). The ability to customize purity and flow allows customers to optimize their oxygen production systems according to specific application requirements, minimizing waste and ensuring efficient system operation.

Key customization features:

Adjustable purity levels (93% to 99.5%).

Flow options up to 5,000 Nm³/h, suitable for both small-scale and large-scale operations.

Customized solutions for industries requiring precise oxygen concentration and continuous delivery.

Youchigases:

Youchigases offers a more standardized product line, providing systems with fixed purity levels and flow rates. While this approach is suitable for smaller-scale, simpler operations, it may not be ideal for industries with specific oxygen requirements. For example, in medical applications or high-precision manufacturing, oxygen purity and flow rate require regular adjustments, and Youchigases’ systems may need additional modifications or external equipment to meet specific industry requirements.

Main limitations:

Limited customization options for high-purity or high-flow rate requirements.

Primarily designed for smaller or less dynamic operations, making it less adaptable to industries requiring constant adjustments to oxygen purity or flow rate.

Core parameter scalability comparison

| Extended dimensions | MINNUO | Youchigases | Capability gap |

| Flow range (Nm³/h) | 5~5000 (module stacking implementation) | 20~2000 (whole machine limit) | ↑150% |

| Purity adjustment range | 93%~99.5% (0.5% step precision control) | 90%~95% (fixed gear position) | ↑4.5 times |

| Pressure output (bar) | 3~20 (dynamic matching of gas equipment) | 5~10 (preset pressure range) | ↑300% |

| Extended response time | 72 hours (add module) | New whole machine purchase required (90+ days) | ↓87% |

Actual data: MINNUO expanded production capacity from 200 Nm³/h to 800 Nm³/h in an automotive plant project in just 68 hours, avoiding production downtime losses of $580,000.

System scalability

MINNUO:

MINNUO’s modular design facilitates scalability, enabling its systems to highly adapt to growing industrial demands. Whether a business has initially low oxygen demand with plans for gradual expansion, or faces seasonal fluctuations in demand, MINNUO provides scalable solutions that grow with the business. As demand increases, customers can expand the system by adding additional oxygen generators, storage tanks, or filtration units. This future-proof design makes MINNUO an ideal solution for businesses with long-term growth plans or unpredictable oxygen demand.

Key Features:

Modular design allows for easy expansion and system upgrades.

Flexible scalability to adapt to changes in oxygen demand and capacity.

Suitable for growing businesses in industries such as steel manufacturing, chemical processing, and wastewater treatment.

Youchigases:

Youchigases are typically designed with fixed capacity, making their systems less adaptable to rapid growth or changing operational demands. This makes them ideal for stable, smaller-scale operations where oxygen demand is expected to remain relatively constant. However, in dynamic environments such as mining or oil extraction, oxygen demand may fluctuate due to shift changes, weather conditions, or expanded operational scale. Youchigases may require more complex reconfiguration or replacement with larger units to meet changing demands.

Key limitations:

Limited flexibility for industries with fluctuating or expanding oxygen demand.

May require replacing the entire system to accommodate future growth, resulting in higher capital investment.

Special scenario solution comparison

| Extreme demands | MINNUO Response Capability | Youchigases limitations |

| Deep-sea drilling platforms | Salt fog corrosion resistance + 30° tilt operation | Maximum tilt angle of 15° |

| Semiconductor electronics gas | 99.999% ultra-pure oxygen + particle control | Cannot provide >99% purity |

| Mobile field hospitals | Container-type rapid deployment (including power generation) | Fixed installation only |

| High-altitude unmanned mines | Remote control + self-maintenance module | Requires regular manual maintenance |

Maintenance and After-Sales Support: MINNUO vs Youchigases

Maintenance Requirements

MINNUO:

MINNUO’s system design is low-maintenance, requiring fewer parts to be replaced or repaired over the equipment’s lifespan. This significantly reduces costs for businesses and minimizes downtime. Regular maintenance intervals typically involve a major overhaul every 2-3 years, depending on the specific model and usage conditions. This extended maintenance interval reduces operational disruptions and helps businesses maintain a continuous and reliable oxygen supply, minimizing the need for frequent interruptions.

Key Features:

Low-maintenance design with fewer components requiring replacement.

Longer overhaul intervals of 2-3 years.

Advanced engineering design minimizes wear and tear, ensuring continuous operation.

Youchigases:

In contrast, Youchigases systems typically require more frequent maintenance, particularly for filters, valves, and other high-wear components. Their maintenance intervals are often more frequent, typically requiring regular maintenance every 6-12 months, depending on system usage and environmental conditions. This more frequent maintenance cycle may increase overall operational costs and downtime, especially in industrial applications where performance stability is critical.

Key limitations:

Components such as filters and valves require more frequent repairs.

Shorter service intervals lead to increased operational disruptions.

Over time, downtime and repair costs may increase.

Core maintenance parameter comparison (based on a 10-year operational cycle)

| Indicators | MINNUO | Youchigases | Gap multiple |

| Major overhaul interval | 25,000 hours (≈3 years) | 8,000 hours (≈1 year) | 3.1x |

| Annual maintenance man-hours | 40 hours | 120 hours | ↑200% |

| Spare parts supply lead time | 72-hour global delivery | Average 28 days | ↓88% |

| Remote support coverage | 98% of faults resolved online | 65% | ↑51% |

| Technical team certification level | 85% of engineers are ASE/CMVP certified | Basic Certified Engineer | Unique |

After-sales Support

MINNUO:

MINNUO specializes in providing comprehensive global after-sales support, ensuring customers receive technical assistance and spare parts with minimal delay. With an extensive network of authorized service centers and specialized operator training programs, MINNUO offers robust support to ensure equipment operates at peak efficiency. Their commitment to customer satisfaction includes 24/7 technical support and emergency response capabilities, minimizing downtime and ensuring smooth operations.

Key Features:

Global support network with accessible service centers.

Comprehensive technical assistance and operator training programs.

Rapid spare parts delivery to minimize repair delays.

24/7 emergency support to ensure quick resolution of issues in urgent situations.

Youchigases:

Youchigases offers adequate customer support, but has a limited number of service centers. This may result in longer spare part delivery cycles and longer wait times for maintenance support, especially in remote areas or countries. As a result, businesses may experience delays in repair and support services, potentially increasing operational risks.

Key Limitations:

Reduced service centers lead to longer wait times for maintenance and support.

Extended spare part delivery times may delay repairs.

Limited global reach in providing rapid after-sales service.

After-Sales Support Scorecard

| Service items | MINNUO Score | Youchigases Score | Gap |

| Technical response speed | 9.8/10 | 6.2/10 | ↑58% |

| Reasonable spare parts prices | 8.7/10 | 7.1/10 | ↑23% |

| Fault resolution rate | 98% | 76% | ↑29% |

| In-depth operational training | VR Simulation Factory | Paper Manual | Generational gap |

Conclusion

For industries that prioritize long-term stability, low maintenance costs, and the ability to operate in harsh environments, the MINNUO PSA oxygen generator is clearly the superior choice. With its robust and durable design, coupled with a commitment to energy efficiency and operational longevity, MINNUO is the ideal solution for industries such as steel manufacturing, healthcare, and chemical processing.

However, if initial cost is the primary consideration and operational conditions are relatively mild, Youchigases may be a viable alternative, offering a more cost-effective solution without requiring the same level of long-term investment. For operations with lower environmental requirements or smaller scales, Youchigases may effectively meet basic needs.

Ultimately, MINNUO’s PSA technology ensures businesses achieve the optimal balance between performance, reliability, and operational costs, making it a reliable partner for industries seeking high-performance oxygen generation systems. Choosing MINNUO means you are not just purchasing equipment but gaining a reliable partner committed to optimizing your oxygen supply needs through exceptional service and ongoing support.

sales2:+86 17506119168

sales2:+86 17506119168