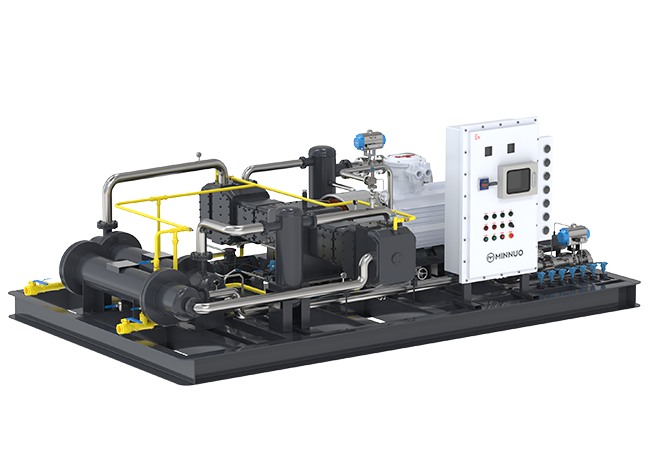

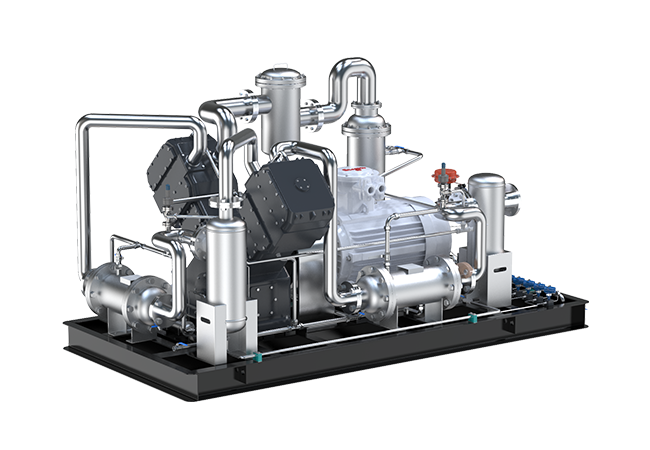

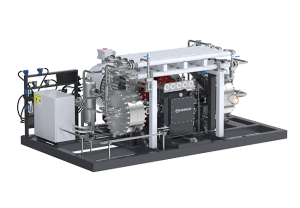

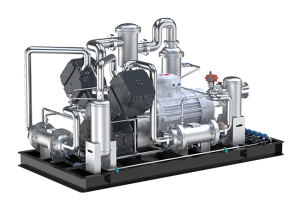

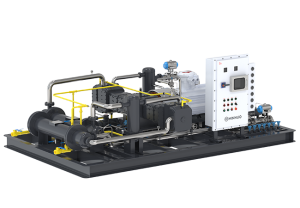

Ammonia Compressor

MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios with air output capacities from 0.2 to 40 m³/min and pressure ranges from 0.8 to 2.6 MPa. They are suitable for harsh environments such as third-level stations, refineries, and docks.

Working Principle

Four steps to achieve efficient ammonia gas compression:

- Intelligent Inhalation: Low-pressure gaseous ammonia enters the compression chamber precisely through a self-regulating intake valve. This valve is equipped with intelligent sensors that monitor the intake parameters in real-time. When operating conditions change, the system adjusts the valve opening based on feedback data to ensure optimal intake volume, reducing energy consumption and wear.

- Precise Compression: The high-precision piston/screw system compresses the gas to the target pressure. Piston compressors rely on reciprocating motion, while screw compressors operate based on screw engagement. Both utilize advanced technologies and control systems for precise compression ratio management.

- Stable Exhaust: High-pressure gas is delivered smoothly to the downstream system through multi-stage buffering. The multi-stage buffering system, made up of multiple buffer tanks and matching valves, absorbs pressure fluctuations, optimizes the gas path, and ensures stable operation of downstream equipment.

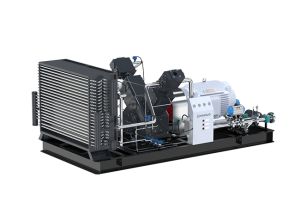

- Efficient Cooling: Patent-pending air-cooled fins and water-cooled coils quickly lower the temperature, ensuring the system’s thermal balance. The air-cooled fins increase the heat dissipation area, while the water-cooled coils use heat exchange for cooling, both of which automatically adjust cooling medium parameters.

Core Advantages

Flexible Adaptation to Industrial Needs

Wide Parameter Coverage: Air output from 0.2 to 40 m³/min and pressure from 0.8 to 2.6 MPa, covering all scenarios from small-scale refilling to large-scale process boosting.

Diverse Structures: Single-cylinder vertical, double-cylinder vertical, and symmetric balance designs to meet different space and efficiency requirements.

Dual Lubrication Systems: Optional pressure lubrication or splash lubrication extends the life of key components by over 30%.

High-Efficiency and Energy-Saving Technology

Air-cooled/Water-cooled Dual Cooling Systems: Increases overall energy efficiency by 25%.

Two-Stage Compression Technology:Reduces energy consumption by 18% during high-pressure output.

Military-Grade Reliability

High-Strength Alloy Cast Body: Anti-corrosion with a service life of up to 100,000 hours.

Standard Intelligent Protection System: Provides overload, overheating, and pressure anomaly protection.

Silent and Environmentally Friendly Design

Water-Cooled Model Noise ≤ 65dB:Meets industrial noise reduction standards.

Fully Sealed Oil Circuit Design: Ensures zero leakage for environmentally friendly operation.

Ammonia Compressor Series

D-Type High-Efficiency Air-Cooled Series

Model | Flow (m³/min) | Pressure (MPa) | Power (kW) | Dimensions (mm) |

DW6.4-0.4 | 6.4 | 2.5 | 132 | 5900×3100×2550 |

DW-10.7-0.4 | 10.7 | 2.5 | 250 | 4800×1600×1200 |

DW-18/250 | / | 2.5 | 320 | 6000*1600*1200 |

V-Type Intelligent Water-Cooled Series

Model | Flow (m³/min) | Pressure (MPa) | Power (kW) | Dimensions (mm) |

VW-6.0-3 | 6 | 0.3 | 30 | 1850×1650×1600 |

VW-9.8-4 | 9.8 | 0.4 | 30 | 1850×1780×1600 |

VW-40-2.5 | 40 | 0.25 | 30 | 3000×1850×1780 |

Application Scenarios

- Energy Storage and Transportation:LNG refueling station ammonia gas boosting (for VW-9.8/4 models).

- Chemical Production: Synthetic ammonia gas transport (DW series recommended).

- Cold Chain Systems:Large cold storage refrigeration cycles (VW-6-3 preferred).

- Hazardous Chemicals Handling: Firefighting tank emergency pressurization (ZW series dedicated).

- Marine Engineering: Dock unloading system integration.

- Refining and Chemical Plants:Continuous process gas treatment.

- Environmental Equipment:Waste gas recovery and boosting systems.

- Military Applications: Precision compression for special gases.

FAQ

A1:Air-cooled models are suitable for water-scarce areas or intermittent operations (e.g., refueling stations), while water-cooled models are recommended for continuous high-load scenarios (e.g., refineries).

A2:The standard maintenance cycle is 2,000 hours, extendable to 3,000 hours for DW series with a self-lubricating system. Smart maintenance reminders are provided.

A3:Custom pressure output from 0.8 to 25 MPa is supported. The ZW series offers ultra-high-pressure solutions.

A4:Standard models ship within 7 working days, while customized models ship within 15 working days (expedited shipping available).

A5:All models have ATEX explosion-proof certification and meet II 2G Ex db IIC T4 Gb standards.

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168