Biogas Recovery and Compression Integrated Solution

Providing biogas purification, compression, storage, and injection turnkey systems, supporting renewable energy, biomethane purification, and power generation applications.

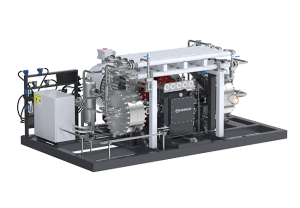

Biogas Recovery and Compression System

MINNUO offers a complete biogas recovery and compression system, covering all stages from raw gas purification to end-use applications, ensuring efficient and stable recovery of biogas resources.

- Desulfurization Unit:Offers both dry desulfurization and activated carbon adsorption options. Dry desulfurization uses iron oxide or zinc oxide, effectively removing hydrogen sulfide from biogas, with an H₂S removal rate >99%. The activated carbon adsorption solution, with its high adsorption capacity, deeply removes impurities like hydrogen sulfide, providing a clean gas source for subsequent processes.

- Biogas Dryer:Available in refrigerated and adsorption types. The refrigerated dryer reduces biogas dew point to -20°C, meeting general humidity control requirements. The adsorption dryer achieves a dew point of -40°C, suitable for applications requiring extremely low humidity in biogas.

- Carbon Dioxide Separation Unit:Uses PSA pressure swing adsorption and membrane separation technologies. PSA technology separates CO₂ from biogas, resulting in methane purity >95%. Membrane separation uses low-energy design, effectively reducing operational costs while ensuring separation efficiency.

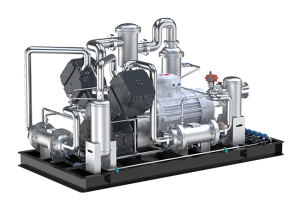

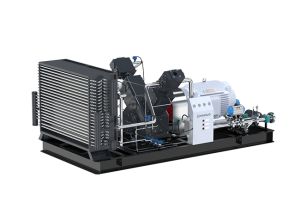

- Biogas Compressor:Available in oil-free piston and screw types. The oil-free piston compressor has a pressure range of 10-250 bar and is easy to maintain; the screw compressor is suitable for large flow continuous operation, ensuring stable biogas delivery.

- Buffer Storage or Injection System:Equipped with high-pressure storage tanks certified by ASME for safe storage; purified biogas can also be injected directly into the natural gas grid, fully complying with the GB 17820 standard.

- Optional Modules:Includes Combined Heat and Power (CHP) interface for waste heat power generation and energy recycling, improving energy efficiency.

Application Scenarios

Livestock Farming and Agricultural Waste Treatment

Recovering biogas from manure not only effectively reduces carbon emissions but also converts waste into clean energy, achieving a win-win for farming and environmental protection.

Food Waste Anaerobic Digestion (AD Plants)

Treating biogas from food waste anaerobic digestion enhances energy utilization of organic waste, improving gas production efficiency by 30% over traditional methods.

Landfill Gas Recovery

Recovering landfill gas through specialized equipment can achieve a methane recovery rate >90%, significantly reducing greenhouse gas emissions and protecting the environment.

Wastewater Treatment Plants (WWTP)

Purifying biogas from sludge can replace fossil fuels, providing a stable energy supply for wastewater treatment plants and reducing operational costs.

Biomethane Purification and Injection into the Grid

Purified biomethane meets vehicle fuel (CNG) or industrial gas standards, enabling efficient energy utilization.

Off-Grid Power Generation (CHP)

Paired with biogas generators, this system ensures energy self-sufficiency in off-grid areas, guaranteeing stable and reliable power supply.

Core Advantages

- Integrated Design of Purification + Compression + Storage:Reduces land area, shortens project timelines, and lowers construction costs.

- Modular Skid-Mounted, Plug-and-Play:Supports quick deployment, especially for remote area projects, reducing implementation complexity.

- Customized Solutions Based on Raw Gas Quality:Precisely matches H₂S, CO₂, humidity, and other parameters in the raw gas to ensure stable system operation.

- Energy Efficient: Compressor specific energy consumption <0.1 kWh/Nm³, reducing annual operation and maintenance costs by 25%, achieving both economic and environmental benefits.

- Compliance with International Emission and Safety Standards: Certified with CE/PED/ATEX, and designed with explosion-proof features to ensure safe system operation.

Featured Equipment Modules

- High-Efficiency Desulfurization Tower: Uses multi-stage reaction bed design to process biogas with H₂S concentrations up to 10,000 ppm, ensuring effective desulfurization.

- Oil-Free Screw Compressor: Equipped with variable frequency drives, offering a flow adjustment range of 30%-100%, adaptable to actual demands.

- Intelligent Membrane Separation System: Selectively separates nitrogen/CO₂, with methane recovery rate >98%, improving biogas resource utilization.

- Containerized Control Room: Integrates PLC and remote monitoring, supporting IoT data access for remote operation and real-time monitoring.

Project Case Study

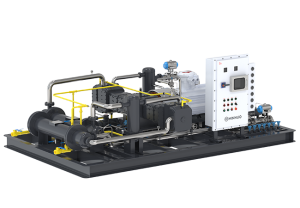

South America 1000Nm³/h Biogas Purification Plant

- Raw Gas Source:Biogas from anaerobic fermentation of cattle manure at a farm, with CH₄ content of 60% and H₂S content of 2000 ppm.

- Core Process:Dry desulfurization, refrigerated drying, and PSA purification, resulting in CH₄ purity >95% biomethane.

- Key Equipment:16 bar oil-free piston compressor, capable of producing 24,000 Nm³ of biomethane per day.

- Project Highlights:Entire skid-mounted containerized layout, completed commissioning and grid connection within 30 days, significantly shortening project cycle.

FAQ

A1: Yes. We offer a customized three-stage desulfurization solution, including dry, wet, and activated carbon methods. First, dry desulfurization removes the majority of H₂S, reducing its concentration to a certain level; then, wet desulfurization further removes the remaining H₂S; finally, activated carbon adsorption achieves deep purification. This solution is suitable for biogas with H₂S concentrations ≤20,000 ppm.

A2: Yes. All systems are modular, and after assembly and testing in the factory, they are shipped in containers. On-site installation requires only simple pipe and electrical connections, with an installation cycle of less than 15 days. This method shortens the project construction time, reduces on-site installation complexity and risk, and minimizes environmental impact.

A3: Yes. We support single-unit purchases and provide commissioning and training services. After delivery, our technicians will install and commission the equipment on-site to ensure proper operation. We also offer EPC turnkey services, providing one-stop solutions from project design, procurement, construction, to commissioning.

A4: The core components have a maintenance-free period of over 8000 hours. We use high-quality equipment and materials, optimize the structure and operational parameters to reduce wear and failure, and offer remote diagnostics. By connecting to IoT data, our technicians can monitor system performance in real-time, identify potential issues, and provide solutions. If equipment failure occurs, we respond quickly and send technicians for on-site repairs, ensuring system stability.

A5: We have intelligent buffer tanks and variable frequency adjustment devices. The intelligent buffer tank automatically adjusts storage capacity based on fluctuations in raw gas flow and pressure, stabilizing the gas flow. The variable frequency adjustment device adjusts compressor parameters in real-time based on buffer tank pressure and flow signals, accommodating gas fluctuations of ±20%.

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168