Biogas is an environmentally friendly, clean and cheap combustible gas produced by microorganisms in anaerobic environment, such as livestock manure, agricultural waste, industrial organic waste, domestic sewage and municipal domestic waste, and its main components are methane, carbon dioxide and hydrogen sulfide. Biogas is mainly purified and used for urban gas, vehicle fuel, hydrogen production, etc.

Biogas is a mixture of gases produced by the fermentation of organic material by microorganisms under anaerobic conditions. Biogas is a mixture of several gases with properties similar to natural gas, the main component being methane. Biogas upgrading and purification can be realized to purify methane. The biogas extraction biogas plant designed and manufactured by Minnuo can effectively remove impurities such as condensate, hydrogen sulfide and carbon dioxide from biogas and maintain a very high recovery rate of CH4.

There are four methods to realize the purification of biogas, which are absorption, variable pressure adsorption, low temperature condensation and membrane separation methods.

Minnuo, as a professional biogas upgrading and purification equipment company, we have first-class biogas upgrading and purification technology, professional systems and low prices, and we constantly follow up the progress of the project from the design of the plan, and we can also customize the biogas purification and bottling units.

Parameter |

Value |

|---|---|

|

Unit scale |

50~20000 Nm3/h |

|

Purity |

CH4≥93% |

|

Pressure |

0.3~3.0Mpa(G) |

|

Methane recovery rate of product |

≥93% |

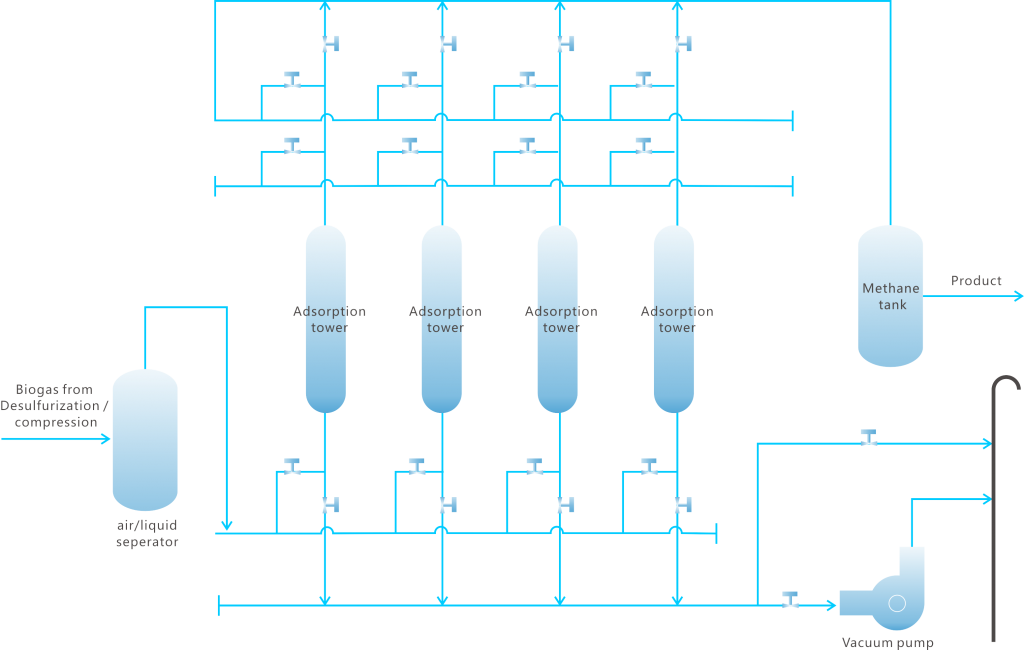

The biogas is desulfurized and compressed, pressurized, and then decarburized and purified by pressure swing adsorption (PSA) to obtain product gas.

Energy saving and consumption reduction is the survival of the enterprise, Minnuo has professional energy-saving air separation technology, which can reduce the energy consumption of air separation equipment by 5%-15% and save the running cost for customers.

Minnuo’s intelligent production workshop improves the accuracy of manufacturing process in the air separation industry, improves the performance of the equipment and shortens the customer’s booking cycle.

Self-developed remote intelligent monitoring system, remote monitoring terminal real-time collection of equipment site data, to achieve fault monitoring, warning, to ensure the safe operation of equipment.

Professional service team, long-term training and guidance on the use and management of users, regular visits by relevant personnel and timely provision of spare parts.

Biogas upgrading system is a facility designed to concentrate methane (CH4) by removing carbon dioxide (CO2), hydrogen sulfide (H2S), and other impurities from raw biogas. Minnuo’s systems utilize advanced biogas purification technology—primarily PSA (Pressure Swing Adsorption)—to transform raw waste gas into high-purity biomethane that meets natural gas quality standards.

As a professional biogas upgrading plant manufacturer, Minnuo offers several core technologies:

Our biogas upgrading equipment stands out due to its high efficiency and reliability:

The biogas purification process is essential for converting raw biogas into a versatile energy source. Raw biogas contains corrosive H2S and non-combustible CO2. Through purification biogas treatment, the final product can be used as:

Absolutely. We provide customized biogas purification system solutions with a wide treatment range from 50 to 20,000 Nm³/h. We offer skid-mounted and containerized designs that are easy to transport and install, making them ideal for livestock farms, sewage treatment plants, and food waste facilities.

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168