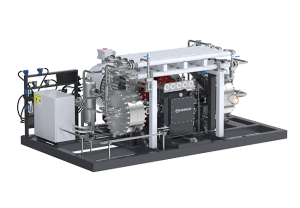

CNG Compressor

The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums, including natural gas, sour gases, and biogas.

With its high-pressure output and wide flow range, it meets the full spectrum of requirements from urban refueling stations to offshore platforms. The ISO-certified heavy-duty structural design ensures stable operation in extreme environments, 24/7.

High-Pressure CNG Compressor

The MINNUO CNG compressor utilizes reciprocating piston technology to achieve efficient compression through a four-step cycle:

- Suction: The piston moves backward to expand the cylinder volume, opening the intake valve, allowing natural gas to enter the cylinder.

- Compression: The piston moves forward to reduce the volume, gradually increasing the gas pressure to the preset value.

- Exhaust: The high-pressure gas pushes open the exhaust valve, transferring the gas to the downstream system.

- Expansion: The piston resets, preparing for the next cycle. This continuous reciprocating motion ensures stable, continuous gas compression output.

Technical Specifications

Parameter Category | Technical Indicators |

Flow Range | 310 – 2680 Nm³/h |

Exhaust Pressure | 21 – 25 MPa (Customizable) |

Motor Power | 75 – 355 kW |

Operating Temperature | -40℃ ~ 60℃ |

Noise Level | ≤75 dB(A) |

Cooling Method | Air Cooling / Water Cooling |

Control System | Siemens PLC Control System |

Application Scenarios

1.CNG Refueling Network

Mother/Child station regular refueling, LNG-CNG mixed station pressurization, Mobile refueling vehicle core units

2.Industrial Processes

Fuel pressurization and delivery for gas-fired power plants, Cycle gas compression in petrochemical plants, Pressure stabilization of process gases in the food and pharmaceutical industries

3.Environmental Energy

Landfill gas/biogas purification and compression, Core equipment for coalbed methane recovery systems

4.Special Scenarios

Associated gas treatment on offshore drilling platforms, Independent power supply systems for polar research stations

Core Advantages

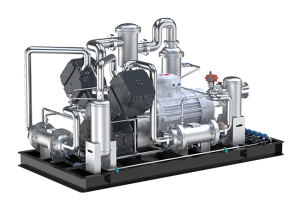

1.Military-grade Structure, 300% Extended Lifespan

- Heavy-duty Design:Alloy steel crankshaft and precision-cast cylinder body, tested for 200,000 fatigue cycles, supporting 24/7 continuous operation.

- Long Maintenance Cycle: Key wear components such as valves and piston rings have a lifespan >8000 hours (industry average 5000 hours).

- Global Stringent Certifications: Compliant with ASME, API 618 standards, passed salt spray, vibration, and high-pressure burst tests.

2.Intelligent Control, Worry-free Safety

- Heavy-duty Design:Alloy steel crankshaft and precision-cast cylinder body, tested for 200,000 fatigue cycles, supporting 24/7 continuous operation.

- Long Maintenance Cycle: Key wear components such as valves and piston rings have a lifespan >8000 hours (industry average 5000 hours).

- Global Stringent Certifications: Compliant with ASME, API 618 standards, passed salt spray, vibration, and high-pressure burst tests.

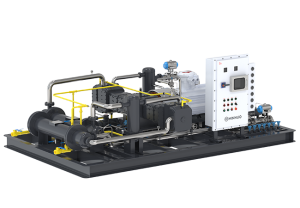

3.Ultra-Quiet, City-Friendly Design

- As low as 75dB(A): Integrated soundproof cover + shock-absorbing base, meeting GB12348 Class II noise standards.

- Compact Skid-mounted Structure:Pre-installed piping and instrumentation, reducing the footprint by 35%, with on-site installation and commissioning completed within 72 hours.

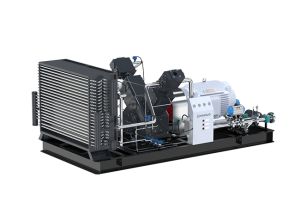

4.Dual Cooling Modes, Suitable for Extreme Environments

- Air Cooling Version: Stable operation in 45°C high-temperature desert environments, reducing maintenance costs by 40%.

- Water Cooling Version:Efficiency remains unaffected in 60°C hot and humid conditions, ideal for coastal/high-humidity regions.

5.Economical and Efficient Power Configuration

- Soft Start Technology: Allows up to 15 start-stop cycles per hour, reducing grid impact by 60%.

- Modular Power: Flexible combinations from 75kW to 355kW, with 18% lower energy consumption compared to traditional models.

6.Global Scene Validation

- Extreme Temperatures:Built-in low-temperature preheating system (-40°C cold start) and high-temperature air cooling compensation module.

- Corrosion-resistant Treatment: Acidic gas versions use 316L stainless steel cylinders and Teflon coatings.

FAQ

A1:No, the skid-mounted structure comes with an integrated shock-absorbing base, allowing direct installation on a 15cm thick concrete platform.

A2:A corrosion-resistant version with 316L stainless steel cylinders and ceramic-coated pistons is available, with H₂S tolerance up to 5,000 ppm.

A3:Yes, it supports OPC UA, Modbus TCP protocols, and provides standard API interfaces for data integration within 2 hours.

A4:A standard toolbox with wear parts (including piston rings, valve discs, and seals) is provided. Replacing a single valve takes just 30 minutes.

A5:We provide a full set of compliance documents: explosion-proof certification (ATEX/IECEx), noise test reports, and safety risk assessment forms.

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168