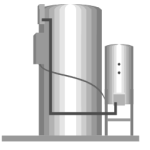

MINNUO’s CO₂ desiccant dryer is a groundbreaking product in the field of gas dehydration, specifically designed for Carbon Capture, Utilization, and Storage (CCUS) projects.

MINNUO’s CO₂ desiccant dryer utilizes both Temperature Swing Adsorption (TSA) and Temperature-Pressure Swing Adsorption (TPSA) processes, combined with an intelligent control system, to achieve a dew point as low as -70℃. This ensures deep dehydration and aligns with global trends in energy efficiency and environmental sustainability.

Achieves zero or minimal emissions during regeneration, meeting stringent environmental standards.

PLC control with remote start/stop functionality, dynamically adjusting adsorption cycles to handle gas fluctuations.

Dual-tower, triple-tower, or multi-tower configurations ensure continuous operation with redundant adsorption capacity.

30% lower energy consumption and noise levels 20% below industry benchmarks.

Suitable for indoor or outdoor installation with rainproof protection, adaptable to extreme conditions.

Parameter | Specification |

Gas Media | CO₂, O₂, He, and other specialty gases |

Outlet Dew Point | -20℃ to -70℃ |

Inlet Gas Temperature | ≤38℃ |

Inlet Oil Content | <0.01 PPM |

Cooling Water | 2~32℃, 0.2~0.5 MPaG |

Control System | PLC control with remote start/stop and fault output |

Regeneration Method | Heated Regeneration (TSA/TPSA) |

Power Supply | 380V/50Hz/3Ph+N+PE (customizable for global voltages) |

Instrument Air | 0.6~1.0 MPaG |

Installation | Indoor or outdoor with rainproof awning, on flat concrete ground |

A: MINNUO dryers have a modular design for easy and cost-effective maintenance. We recommend checking the desiccant every 6 months, including saturation level, damage, and regeneration efficiency. Annual maintenance includes desiccant replacement, valve sealing inspection, filter cleaning, and sensor calibration. Our intelligent diagnostic system provides early warnings to minimize downtime.

A: Yes. MINNUO dryers are designed with moisture-proof features and special coatings for environments with up to 95% relative humidity. Under extreme conditions, the system automatically increases regeneration frequency and uses heated regeneration to ensure desiccant recovery. Additionally, a pre-cooling unit reduces inlet gas humidity for optimal dehydration.

A: Yes. MINNUO dryers can be customized to achieve dew points as low as -80℃ by optimizing desiccant formulation, increasing the number of adsorption towers, and extending adsorption cycles. For ultra-low dew point applications (e.g., semiconductor industry), we recommend triple or multi-tower designs combined with deep cooling processes to meet the highest purity standards.

A: MINNUO dryers feature low-noise design, operating below 65dB to meet industrial quiet standards. We further reduce noise through:

A: Yes. MINNUO dryers are equipped with advanced PLC control and IoT modules, allowing real-time monitoring of key parameters (e.g., dew point, temperature, pressure) via computer or mobile devices. The system supports remote start/stop, parameter adjustment, and fault diagnostics, with alerts sent via email or SMS for prompt response.

A: MINNUO dryers incorporate multiple energy-saving technologies, reducing energy consumption by over 30% compared to traditional systems. Key measures include:

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168