Minnuo specializes in the development and engineering contracting of coke oven gas purification, coke oven gas hydrogen purification, dry desulfurization technology for the metallurgical and coking industries, as well as the research, development and production of desulfurizers, adsorbents, and oxygen and nitrogen generation equipment.

Coke oven gas contains impurities such as tar, naphthalene, benzene, inorganic sulfur and organic sulfur. In order to make full use of coke oven gas, purify it, reduce the impurity content in it, make the combustion emission meet the environmental – protection requirements and use it as raw materials for chemical production, a mature technology is applied. This technology is widely used in power plants and coal – chemical industries.

Coke oven gas is produced during coking, a process that involves the dry distillation of coal at high temperatures and in the absence of oxygen. Specifically, the coal is heated in a coke oven and converted to coke through dry distillation while releasing a flammable gas, known as coke oven gas.

Coke oven gas belongs to medium calorific value gas, and its calorific value is 17~19MJ per standard cubic meter, which is suitable to be used as fuel for high temperature industrial furnace and city gas. Coke oven gas contains high amount of hydrogen, which is used to synthesize ammonia after separation, and other components such as methane and ethylene can be used as raw materials for organic synthesis.

Coke oven gas is toxic and an explosive gas, the explosion limit in air is 5%~30%.

Coke oven gas is a mixture, and its yield and composition vary according to the quality of the coal used for coking and the conditions of the coking process, generally each ton of dry coal can produce coke oven gas of 300~350m3 (standard state).

Gas | Concentration |

H₂ | 55%~60% |

CH₄ | 23%~27% |

CO | 5%~8% |

CnHm | 2%~4% |

CO₂ | 1.5%~3% |

O₂ | 0.3%~0.8% |

N₂ | 3%~7% |

Parameter |

Value |

|---|---|

|

Coke oven gas processing capacity |

1000~460000Nm³/h |

|

Naphthalene content of refined gas |

≤ 1mg/Nm³ |

|

Refined gas tar content |

≤ 1mg/Nm³ |

|

Sulfur content of refined gas |

≤ 0.1mg/Nm³ |

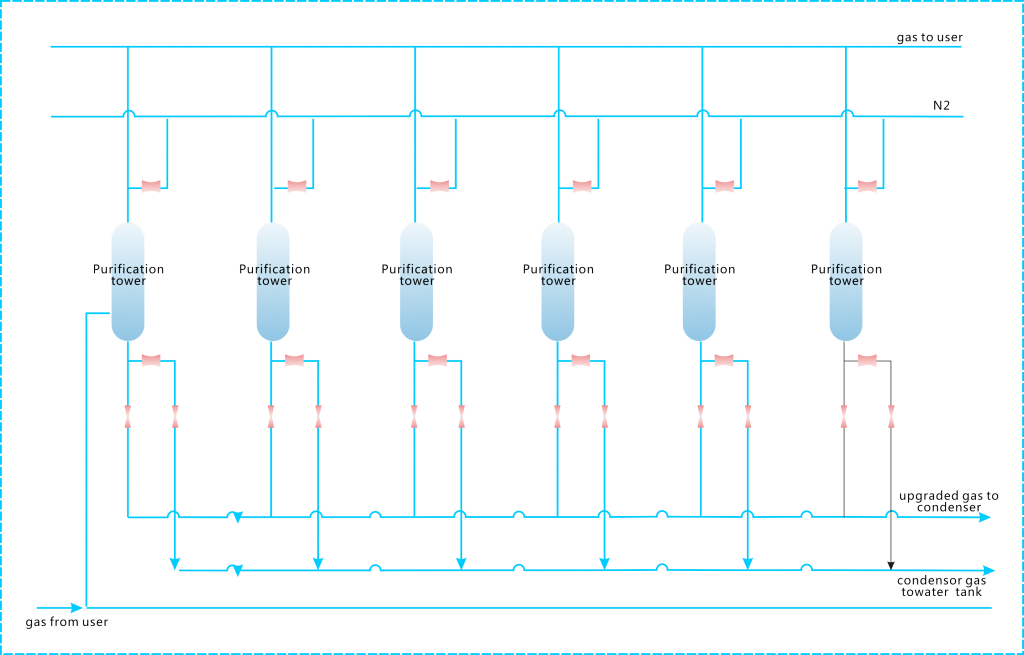

Purified gas is prepared from coke oven gas after tar removal, naphthalene removal, benzene removal, atmospheric (pressurized) desulfurization and fine desulfurization.

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168