Minnuo, as a professional gas purification and separation equipment manufacturer and supplier. We have rich experience in designing, manufacturing and installing high purity food grade carbon dioxide gas purification equipment. Food grade carbon dioxide plant is widely used in coal chemical industry, petrochemical, electric power, alcohol, building materials, ethylene, steel, oil and gas fields and other occasions to recover carbon dioxide gas of different concentrations.

Food grade carbon dioxide is mainly used in various carbonated beverages and food preservation. Particularly in carbonated beverages, it plays a crucial role in regulating the flavor and providing a refreshing sensation that helps relieve the heat in summer. The production and manufacturing process of food grade carbon dioxide demands strict compliance with health and safety standards. This is essential to ensure that the final food products are free from harmful substances and microorganisms, safeguarding the health of consumers.

Our production process features mature technology, ensuring safe and reliable operation as well as high yield. Moreover, the operation control system is both reliable and practical, enabling efficient production and easy management.

Minnuo, as a professional gas purification and separation equipment manufacturer and supplier, has rich experience in designing, manufacturing and installing high purity food grade carbon dioxide gas purification equipment. Food grade carbon dioxide plant is widely applied in coal chemical industry, petrochemical,industry electric power, alcohol, building materials, ethylene, steel, oil and gas fields and other occasions to recover carbon dioxide gas of different concentrations. The scale of a single set of food-grade carbon dioxide plant has reached 600kt/a. At the same time, we have successfully developed a complete set of small and fine plants for the production of 50-500kg/h food-grade liquid carbon dioxide by combustion of carbon-containing raw materials, and a carbon dioxide plant of electronic grade quality standard.

Food grade CO2 plants are systems specifically designed to produce and purify CO2 gas that complies with food safety standards. These plants utilize high purity raw materials and advanced filtration and purification technologies to ensure that the output CO2 meets the stringent quality requirements applicable to food processing. They are extensively used in the food industry for aerating carbonated beverages, aerating food packaging to preserve freshness, and as refrigerants in freezing and cooling processes, and are a key component in ensuring food safety and extending product shelf life.

● Highly positioned product quality standards.

● Diversified purification methods in the first stage.

● Advanced and perfect testing methods, high CO2 purity, stable and realizing quality.

● High degree of automation of equipment, realize full DCS or PLC control.

Choose Minnuo to be your food grade carbon dioxide equipment manufacturer and supplier, we have professional technology, rich cases and perfect production design management sales experience, which can assist you to make your gas separation and purification business more successful.You can contact our engineers for professional equipment customization and design if needed!

Parameter |

Value |

|---|---|

|

Unit scale |

1000~100000t/a |

|

Purity |

98%~99.9% (v/v) |

|

Pressure |

~2.5MPa(G) |

|

Temperature |

~ -15˚C |

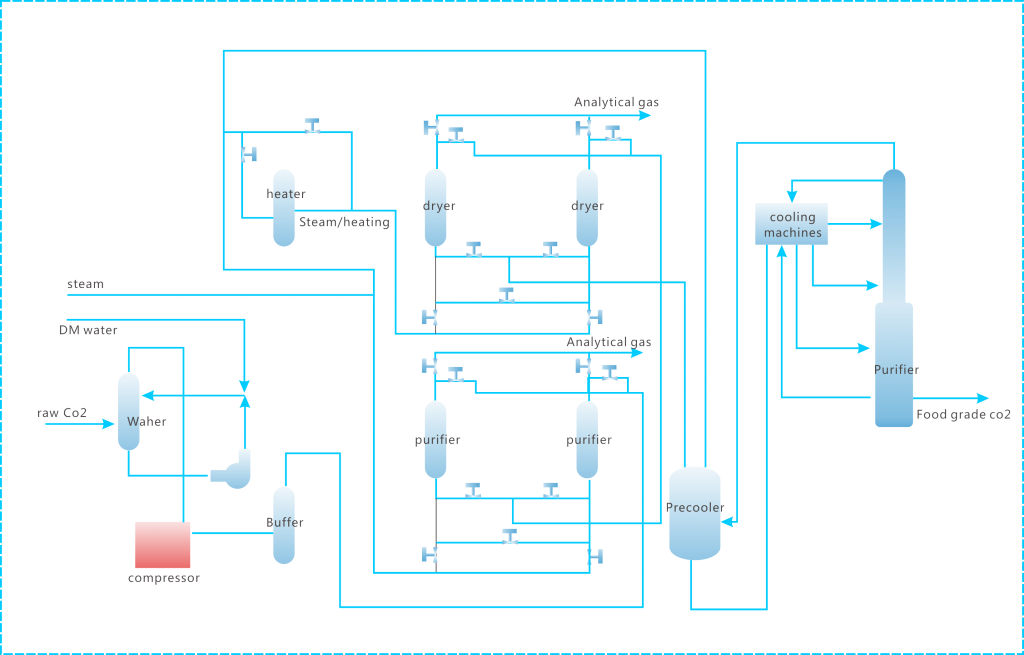

The MDEA residue in the feed gas is removed after the raw material is washed with water, and then compressed, purified and dried to remove trace organic substances such as alcohol in the gas and remove the odor. After distillation and purification, the trace low boiling point gas dissolved in CO2 is further removed, and high-purity food-grade CO2 is obtained and sent to the storage tank or filled.

It complies with the national standards of GB10621-2023 Liquid Carbon Dioxide for Food Additives, GB1917-94 Liquid Carbon Dioxide for Food Additives (Fermentation Method) and the food grade carbon dioxide standard of Coca-Cola Company.

We will contact you within 1 working day, please pay attention to the email with the suffix “@minnuogas.com”.

sales2:+86 17506119168

sales2:+86 17506119168