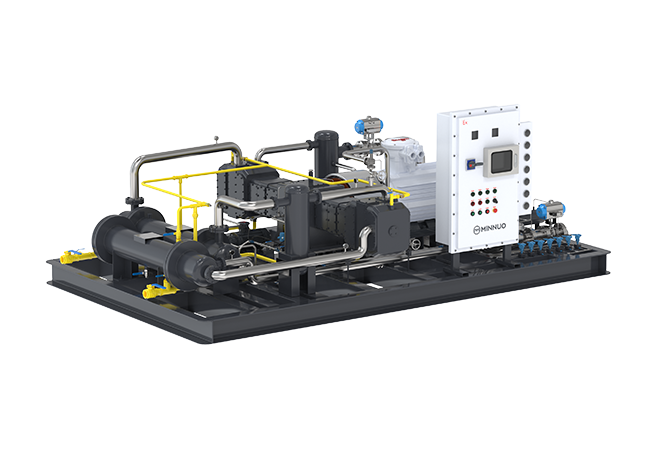

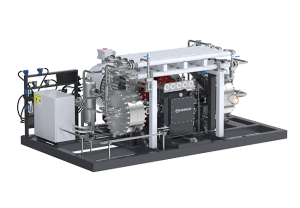

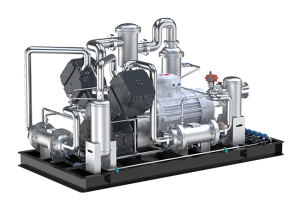

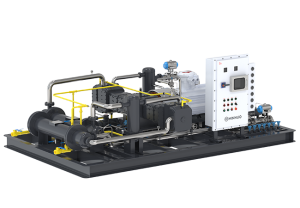

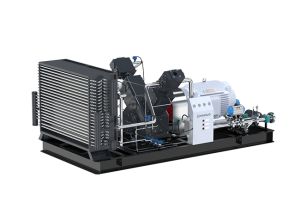

Helium Compressor

MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from 0.1 to 30 MPa. These compressors are ideal for helium recovery, storage, and pressurization needs in industrial processes. With a modular design and multi-stage compression technology (1 to 5 adjustable stages), our compressors can flexibly accommodate various flow (10-20,000 cubic meters/hour) and pressure requirements. They are capable of compressing fresh helium, mixed gases, and recovered helium, significantly reducing user costs.

Key Features of Helium Compressor

- Lubrication Method:Available in both oil-lubricated and oil-free options, meeting different purity requirements.

- Cooling System:Dual mode of air cooling and water cooling, suitable for high-temperature or heavy-load conditions.

- Intelligent Control: Fully automated control system, providing real-time monitoring of pressure, flow, and leakage risks.

Product Advantages

1.Zero Leakage Safety Assurance

A fully sealed design with a crankcase exhaust recovery system, combined with specialized adsorption filtration technology, ensures helium purity above 99.95%, eliminating leakage risks.

2.High Durability and Strength

- Heavy-duty construction supports 24/7 continuous operation, suitable for demanding environments such as semiconductor manufacturing and aerospace.

- Low-speed operation reduces mechanical wear and extends service life.

3.Flexible Adaptation to Industrial Needs

- Customizable solutions, from material selection to pressure stages, tailored to suit various gases like helium and argon.

- Compact design (minimum size 1680×800×1300 mm) saves space, with portable models to meet mobility needs.

4.Energy Efficiency

- Two-stage compression and oil mist separation technology reduce energy consumption by up to 30%.

- Air-cooling systems require no additional cooling water, resulting in lower operational and maintenance costs.

Operating Principle

The MINNUO helium compressor achieves efficient compression through the following steps:

1.Intake and Purification: Gas is filtered through dedicated filters to remove impurities, ensuring the purity of the compressed medium.

2.Multi-stage Compression: The reciprocating piston increases pressure step by step (up to 5 stages), reaching a maximum pressure of 30 MPa.

3.Cooling and Recovery:

- Air cooling: Forced air convection heat dissipation, suitable for small and medium-sized equipment.

- Water cooling: Recirculating cooling water system ensures stability under heavy-load conditions.

4.Sealed Output: After oil mist separation and adsorption filtration, high-purity helium is delivered to storage tanks or end-use applications.

Application Scenarios

Industry | Typical Applications | Core Requirements Met |

Semiconductor Manufacturing | Vacuum systems, ion implantation equipment | High-purity helium (99.95%+), zero leakage |

Aerospace Engineering | Liquid hydrogen/liquid oxygen propellant pressurization | Ultra-high pressure (20-30 MPa), low-temperature resistance |

Nuclear and High Energy Physics | Particle accelerator cooling, nuclear reactor protection gases | Continuous operation, radiation-resistant materials |

Industrial Gas Recovery | Helium re-compression and bottling | Multi-stage compression, low energy consumption |

Medical and Research | MRI cooling systems | Silent operation (<74dB), oil-free lubrication |

Product Types and Technical Parameters

Model | Discharge Capacity (m³/h) | Intake Pressure (MPa) | Discharge Pressure (MPa) | Motor Power (kW) | Cooling Mode | Dimensions (L×W×H, mm) | Weight (kg) |

VW-0.5/150 | 30 | Atmospheric Pressure | 15.0 | 15 | Air Cooling | 1680×800×1300 | 1000 |

VW-0.83/150 | 50 | Atmospheric Pressure | 15.0 | 22 | Air Cooling | 1680×800×1300 | 1000 |

VW-1.33/150 | 80 | Atmospheric Pressure | 15.0 | 30 | Air Cooling | 1680×800×1300 | 1100 |

ZW-2/160 | 120 | Atmospheric Pressure | 16.0 | 37 | Air Cooling | 2100×1180×1960 | 2800 |

ZW-3/200 | 180 | Atmospheric Pressure | 20.0 | 75 | Air Cooling | 2180×1250×2360 | 3600 |

ZW-3.34/150 | 200 | Atmospheric Pressure | 15.0 | 75 | Air Cooling | 2180×1250×2360 | 3600 |

ZW-41/72-80 | 250 | 7.2 | 8.0 | 90 | Air Cooling | 2180×1250×2360 | 3200 |

ZW-5/80 | 300 | Atmospheric Pressure | 8.0 | 110 | Air Cooling | 3150×1350×2360 | 4300 |

ZW-3/2-250 | 540 | 0.2 | 25.0 | 110 | Air Cooling | 2180×1250×2360 | 3200 |

ZW-5/150 | 200 | 0.1 | 8.0 | 132 | Air Cooling | 3150×1350×2360 | 4500 |

ZW-6/200 | 540 | 0.2 | 10.0 | 132 | Air Cooling | 3150×1350×2360 | 4500 |

ZW-3.33/1-80 | 200 | 0.1 | 8.0 | 55 | Air Cooling | 2180×1250×2360 | 3200 |

LW-8/150 | 480 | Atmospheric Pressure | 15.0 | 132 | Water Cooling | 3000×1950×2450 | 4500 |

LW-7.5/200 | 450 | Atmospheric Pressure | 20.0 | 160 | Water Cooling | 3200×1950×2450 | 4200 |

DW-8/160 | 480 | Atmospheric Pressure | 16.0 | 132 | Air Cooling | 4500×3300×1850 | 15000 |

DW-8/220 | 480 | Atmospheric Pressure | 22.0 | 160 | Air Cooling | 4500×3300×1850 | 16000 |

DW-10/150 | 600 | Atmospheric Pressure | 15.0 | 185 | Air Cooling | 4500×3300×1800 | 17000 |

DW-18/250 | 1080 | Atmospheric Pressure | 25.0 | 320 | Air Cooling | 4500×3400×1800 | 18000 |

FAQ

A1:Designed primarily for helium, argon, and other rare gases, these compressors support mixed gas compression, but a composition analysis is required to ensure compatibility.

A2:

Oil-free lubrication: Suitable for medical or food-grade helium to avoid oil contamination.

Oil lubrication: More cost-effective, ideal for industrial recovery applications.

A3:

Yes, the DW series can be directly connected to storage tanks, with bottling pressures up to 25 MPa and equipped with intelligent safety valves to prevent over-pressurization.

A4:Routine maintenance is required every 2000 hours, with a focus on checking seals and cooling systems. Water-cooled models require regular descaling, while air-cooled models need dust removal.

A5:

A closed-loop system and emission recovery design result in a leakage rate of less than 0.1%, and with the purification module, helium can be reused multiple times.

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168