Hydrogen Compressor

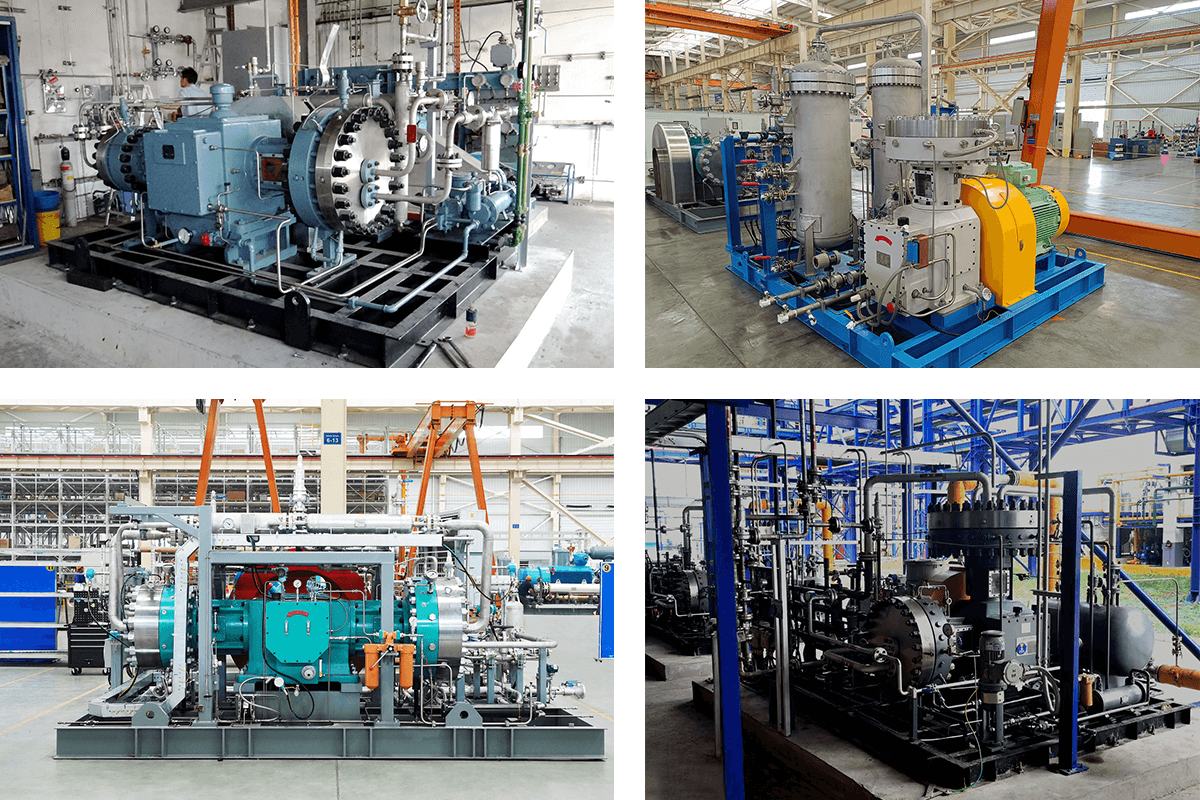

With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our units are successfully operating in various hydrogen applications, delivering a combined installed horsepower exceeding 2 million.

Types and Applications of Hydrogen Compressors

Hydrogen compressors are primarily classified into diaphragm-type and reciprocating (piston-type) compressors. They are widely utilized in industrial gases, food and pharmaceuticals, petrochemicals, aerospace, nuclear power, military equipment, and scientific research.

What is a Hydrogen Compressor?

A hydrogen compressor discharges hydrogen collected from water electrolyzers for storage and transport. Common applications include ship engineering, industrial processing, and hydrogen refueling stations. These compressors typically operate at pressures exceeding 15,000 psi to enable efficient storage. The most commonly used types are piston and metal diaphragm compressors, collectively known as reciprocating compressors.

Role of Hydrogen Compressor

Hydrogen compressors are essential for hydrogen storage and transportation. MINNUO offers various models to support the entire hydrogen energy chain, including:

- Hydrogen production from methanol, natural gas, and coal gas

- Hydrogen production by water electrolysis

- Hydrogen supply for hydrogen refueling stations

- Benzene hydrogenation

- Tar hydrogenation

- Catalytic cracking

- Other hydrogen boosting processes

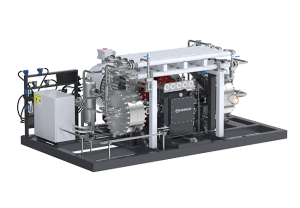

Diaphragm Compressors

Diaphragm compressors are the core pressurization equipment for hydrogen refueling stations. The diaphragm fully isolates the cylinder from the oil chamber, ensuring exceptional sealing and maintaining hydrogen purity. Compression is achieved through reciprocating diaphragm motion during oil pressure fluctuations.

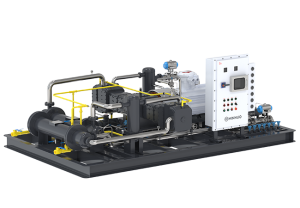

MINNUO Diaphragm Compressors

- Four main types: V, Z, D, L

- 26 series, nearly 900 models

- Maximum displacement: 3,000 Nm³/h

- Maximum pressure: 100 MPa

- Maximum piston force: 250 kN

- Maximum drive power: 450 kW

- High operational safety, minimal gas leakage risk

- Low procurement cost, compact design, and energy efficiency

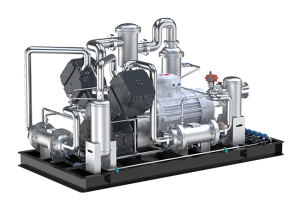

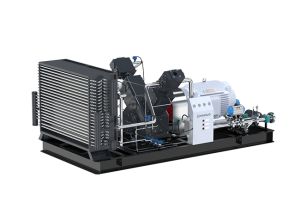

Reciprocating Compressors

Piston-type hydrogen compressors function through a crankshaft-driven system, where connecting rods move the piston up and down to compress hydrogen. The piston rings act as seals, and lubrication ensures smooth operation.

MINNUO Reciprocating Compressors

- Four main types: P, L, D, M

- 19 series, nearly 700 models

- Maximum displacement: 4,000 Nm³/min

- Maximum pressure: 20 MPa

- Maximum piston force: 800 kN

- Maximum drive power: 4,500 kW

- PLC automatic control

- Multiple cooling options: air, water, mixed

- Various installation options: skid-mounted, fixed, soundproof cabin

Diaphragm Compressor Technology & Benefits

Key Advantages

A diaphragm compressor features a flexible membrane separating two chambers—one containing hydrogen and the other filled with a non-reactive gas like nitrogen. Increasing pressure in the nitrogen chamber compresses hydrogen in the adjacent chamber, enabling storage and transport at high pressures.

- Lubrication-free cylinder ensures no contamination, achieving 99.999% purity

- Ideal for compressing high-value rare gases, toxic, flammable, or radioactive gases

- Excellent heat dissipation and high-pressure capability with two-stage compression

- Close to isothermal compression, enhancing efficiency and safety

- Widely used in industrial gas, pharmaceuticals, petrochemicals, aviation, military, and research applications

Diaphragm Compressor Technology & Benefits

G1 Small diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 80kg

- Maintenance maximum space: the circle shall be not less than 1 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GD0-3/200 | 3 | ATM | 20 | / | 750 | 2.2 | 600×500×400 | 200 |

| GL1-5/200 | 5 | ATM | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13 | 10 | ATM | 1.3 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13-200 | 10 | 1.3 | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-5/1-160 | 5 | 0.1 | 16 | 300 | 450 | 3 | 1350×600×950 | 550 |

| GL1-10/4-160 | 10 | 0.4 | 16 | 400 | 600 | 4 | 1350×600×950 | 520 |

| GL1-8/2.5-160 | 8 | 0.25 | 16 | 400 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 15 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/6-200 | 5 | 0.6 | 20 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 16 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/13-400 | 5 | 1.3 | 40 | 300 | 400 | 3 | 1350×600×950 | 500 |

| GL1-15/10-150 | 15 | 1 | 15 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-10/7-320 | 10 | 0.7 | 32 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-5/4-350 | 5 | 0.4 | 35 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100×600×950 | 450 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100×600×950 | 420 |

| GZ1-5/30-400 | 5 | 3 | 40 | 300 | 400 | 3 | 1100×600×950 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1100×600×950 | 420 |

G2 Medium-sized diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 100kg

- Maintenance maximum space: the circle shall be not less than 1 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GD0-3/200 | 3 | ATM | 20 | / | 750 | 2.2 | 600×500×400 | 200 |

| GL1-5/200 | 5 | ATM | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13 | 10 | ATM | 1.3 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13-200 | 10 | 1.3 | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-5/1-160 | 5 | 0.1 | 16 | 300 | 450 | 3 | 1350×600×950 | 550 |

| GL1-10/4-160 | 10 | 0.4 | 16 | 400 | 600 | 4 | 1350×600×950 | 520 |

| GL1-8/2.5-160 | 8 | 0.25 | 16 | 400 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 15 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/6-200 | 5 | 0.6 | 20 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 16 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/13-400 | 5 | 1.3 | 40 | 300 | 400 | 3 | 1350×600×950 | 500 |

| GL1-15/10-150 | 15 | 1 | 15 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-10/7-320 | 10 | 0.7 | 32 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-5/4-350 | 5 | 0.4 | 35 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100×600×950 | 450 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100×600×950 | 420 |

| GZ1-5/30-400 | 5 | 3 | 40 | 300 | 400 | 3 | 1100×600×950 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1100×600×950 | 420 |

G3 Medium-sized diaphragm compressor

- Structure: Z, L,V, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 800kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GD0-3/200 | 3 | ATM | 20 | / | 750 | 2.2 | 600×500×400 | 200 |

| GL1-5/200 | 5 | ATM | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13 | 10 | ATM | 1.3 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13-200 | 10 | 1.3 | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-5/1-160 | 5 | 0.1 | 16 | 300 | 450 | 3 | 1350×600×950 | 550 |

| GL1-10/4-160 | 10 | 0.4 | 16 | 400 | 600 | 4 | 1350×600×950 | 520 |

| GL1-8/2.5-160 | 8 | 0.25 | 16 | 400 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 15 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/6-200 | 5 | 0.6 | 20 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 16 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/13-400 | 5 | 1.3 | 40 | 300 | 400 | 3 | 1350×600×950 | 500 |

| GL1-15/10-150 | 15 | 1 | 15 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-10/7-320 | 10 | 0.7 | 32 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-5/4-350 | 5 | 0.4 | 35 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100×600×950 | 450 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100×600×950 | 420 |

| GZ1-5/30-400 | 5 | 3 | 40 | 300 | 400 | 3 | 1100×600×950 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1100×600×950 | 420 |

G4 Medium-sized diaphragm compressor (compact structure)

- Structure: D-type (two, three, four cylinders)

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled

- Maintenance maximum weight per piece: 1000kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | T | |

| GD4-90/200 | 90 | ATM | 20 | 3200 | 430 | 45 | 4000×2850×2000 | 10.8 |

| GD4-100/160 | 100 | ATM | 16 | 3700 | 430 | 45 | 4000×2850×2000 | 10.8 |

| GD4-240/16-300 | 240 | 1.6 | 30 | 4700 | 360 | 55 | 3800×2600×1800 | 8.5 |

| GD4-240/6-150 | 240 | 0.6 | 15 | 5000 | 400 | 55 | 3800×2600×1800 | 9 |

| GD4-300/15-210 | 300 | 1.5 | 21 | 5300 | 400 | 75 | 3800×2600×1800 | 9.5 |

| GD4-800/12-40 | 800 | 1.2 | 4 | 5400 | 400 | 75 | 3800×2600×1800 | 9.2 |

| GD4-200/15-350 | 200 | 1.5 | 3.5 | 4600 | 360 | 55 | 3800×2600×1800 | 9 |

| GD4-300/5-52 | 300 | 0.5 | 5.2 | 4800 | 430 | 55 | 3800×2600×1800 | 9 |

| GD4-870/11-31 | 870 | 1.1 | 3.1 | 5000 | 420 | 55 | 3800×2850×2000 | 9.5 |

| GD4-240/5-140 | 240 | 0.5 | 14 | 5000 | 400 | 55 | 3800×2600×1800 | 9 |

| GD4-225/9-200 | 225 | 0.9 | 20 | 5000 | 420 | 55 | 3800×2600×1800 | 9.5 |

| GD4-300/5-52 | 300 | 0.5 | 5.2 | 5000 | 430 | 55 | 3800×2600×1800 | 9.5 |

| GD4-280/0.18-5 | 280 | 0.018 | 0.5 | 4000 | 420 | 45 | 4200×2600×2100 | 15 |

| GD4-240/0, 24-6.17 | 240 | 0.024 | 0.617 | 4000 | 420 | 45 | 4200×2600×2100 | 14 |

| GD4-300/10-250 | 300 | 1 | 25 | 5500 | 420 | 75 | 3800×2600×1800 | 9.5 |

G5 Super-large diaphragm compressor

- Structure: D-type (two, three, four cylinders)

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled

- Maintenance maximum weight per piece: 1500kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | T | |

| GD5-150/200 | 150 | ATM | 20 | 7000 | 430 | 90 | 4400×2850×2200 | 13 |

| GD5-525/6-200 | 525 | 0.6 | 20 | 12000 | 400 | 132 | 3800×2700×2000 | 10.8 |

| GD5-250/0.3-12 | 250 | 0.03 | 1.2 | 4700 | 375 | 55 | 4200×2900×1800 | 14 |

| GD5-2900/45-120 | 2900 | 4.5 | 12 | 13200 | 429 | 160 | 4000×2900×2450 | 16 |

| GD5-9000/78-83 | 9000 | 7.8 | 8.3 | 3700 | 450 | 45 | 3800×2600×2500 | 15 |

| GD5-1300/45-220 | 1300 | 4.5 | 22 | 13500 | 429 | 160 | 4000×2900×2450 | 16 |

| GD5-8000/235-250 | 8000 | 23.5 | 25 | 3800 | 429 | 45 | 3800×2600×2500 | 15 |

| GD5-500/0.8-10 | 500 | 0.08 | 1 | 6800 | 429 | 75 | 4400×2850×2200 | 16 |

| GD5-500/10-200 | 500 | 1 | 20 | 12000 | 400 | 132 | 3700×2750×2000 | 10 |

| GD5-550/17-200 | 550 | 1.7 | 20 | 9500 | 400 | 110 | 3700×2750×2000 | 10 |

| GD5-1080/5-31.5 | 1080 | 0.5 | 3.15 | 12000 | 429 | 132 | 4400×2850×2200 | 14 |

| GD5-500/0.7-23 | 500 | 0.07 | 2.3 | 9500 | 429 | 110 | 4400×2850×2200 | 14 |

| GD5-600/15-350 | 600 | 1.5 | 35 | 12800 | 429 | 160 | 4000×2850×2100 | 12 |

| GD5-4500/185-190 | 4500 | 18.5 | 19 | 5000 | 420 | 45 | 3800×2600×2500 | 15 |

| GD5-1000/15-180 | 1000 | 1.5 | 18 | 15000 | 420 | 160 | 4000×2850×2100 | 12 |

Project Case Study

FAQ

A1:

- Diaphragm compressorsuse a flexible diaphragm to separate the oil and hydrogen chambers, ensuring ultra-high purity (99.999%) and suitability for ultra-high pressure applications up to 100MPa.

- Reciprocating compressorsrely on piston motion for compression and sealing, excelling in medium-pressure (20MPa) and high-flow (up to 4000Nm³/min) scenarios.

A2:

Three key technological advantages:

- Zero-leakage designensures hydrogen purity (ISO 22734 certified).

- Ultra-high pressure capability (100MPa)meets the 70MPa storage tank pressure requirement.

- High single-unit flow rate (3000Nm³/h)supports dual-pressure refueling at 35MPa and 70MPa.

A3:

MINNUO ensures safety with ASME B31.12-compliant materials and a three-tier protection system:

- Burst discsfor emergency pressure relief.

- 4-20mA pressure sensorsfor real-time monitoring.

- HIP treatmentto eliminate metal stress.

A4:

Intelligent maintenance system:

- Small units (G1): Piston rings replaced every 2,000 hours.

- Medium units (G3): Diaphragm lifespan inspected every 5,000 hours.

- Large units (G5): Equipped with IoT-based predictive maintenance.

A5:

Tiered selection strategy:

- Small-scale (<100kg/day): G1 diaphragm compressor + air cooling.

- Medium-scale (100-500kg/day): G3 diaphragm compressor + water cooling.

- Large-scale (>500kg/day): G5 diaphragm compressor cluster or P-series reciprocating compressor (4500kW).

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168