Your One-Stop Hydrogen Energy Solutions Provider

From on-site hydrogen generation to purification, compression, and storage – we offer fully integrated, customizable hydrogen systems for industrial and energy applications.

Turnkey hydrogen energy solutions

We provide turnkey solutions, including:

- Hydrogen Generation Units:Utilizing PSA (Pressure Swing Adsorption) or PEM (Proton Exchange Membrane) electrolysis technologies, hydrogen production capacity ranges from 5 to 1000 Nm³/h, offering flexible scalability to meet the hydrogen needs of businesses of all sizes, from small factories to large industrial facilities.

- Purification System:Employing a four-stage filtration process, we efficiently remove CO, CO₂, moisture, sulfur compounds, and other impurities from hydrogen, ensuring hydrogen purity ≥99.99%, providing pure hydrogen for industries with stringent purity requirements.

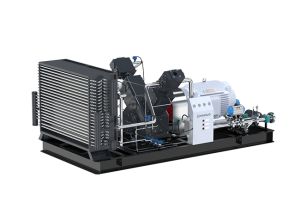

- Hydrogen Compressors:With an oil-free lubrication design and pressure range from 15 to 450 bar, these compressors are specifically designed for continuous industrial operation, ensuring stable performance and extending equipment lifespan.

- Storage Solutions:Offering options such as buffer tanks (1-50m³), high-pressure gas cylinder groups (200-500 bar), and cryogenic liquid hydrogen storage tanks, allowing you to choose the most suitable storage method based on your needs.

- PLC Control System:Integrating safety interlocks, remote monitoring, and data traceability functions, meeting SIL-2 safety standards. This system provides comprehensive safety protection for your hydrogen system, enabling you to monitor equipment status in real time through remote monitoring, with data traceability ensuring each process step is documented.

Application Scenarios

Our hydrogen energy systems are ideal for the following fields:

Hydrogen Refueling Stations (HRS}

45 MPa fast refueling solutions, supporting dual pressure cascade storage, greatly reducing refueling time for vehicles and improving the operational efficiency of hydrogen refueling stations, promoting the adoption of hydrogen fuel cell vehicles.

Glass / Metal / Electronics Manufacturing

Providing hydrogen to hydrogen-fired furnaces as a reducing protective gas, improving product quality, reducing impurities, and meeting industry demands for high-quality products.

Ammonia & Methanol Production

Adapting green hydrogen alternatives to reduce carbon emissions during traditional production processes, promoting a low-carbon and environmentally friendly industry development.

Food and Chemical Hydrogenation

Playing a crucial role in the hydrogenation process of edible oils and pharmaceutical intermediates, providing a reliable hydrogen source for food and pharmaceutical production.

Renewable Energy Storage

Using Power-to-Gas (P2G) systems to convert unused electricity from wind and solar power into hydrogen for storage, enabling efficient utilization of renewable energy and reducing energy waste.

Core Advantages

- Fully Integrated Systems: From gas source preparation to end-use application, we provide end-to-end delivery services, eliminating the risks of coordinating multiple suppliers and saving you time and effort, ensuring smoother project implementation.

- Oil-Free Compression Technology:Featuring ceramic-coated piston rings and labyrinth seals, our hydrogen compressors effectively prevent oil contamination during hydrogen compression, ensuring zero contamination and guaranteeing hydrogen purity, even in demanding applications.

- Modular Skid Design: All units are pre-assembled in standard containers, allowing for quick integration on-site within 72 hours, significantly shortening project construction timelines and enabling faster production startup.

- Triple Safety Certification: Our products are certified by ATEX explosion protection directive, CE Machinery Directive, and ISO 22734 Electrolyzer System certification, ensuring product quality and safety, giving you peace of mind.

- Flexible Customization:Offering customizable configurations for flow (5-1000+ Nm³/h), pressure (15-450 bar), and purity (99.9%-99.999%), we can tailor solutions to meet your specific needs, no matter how specialized.

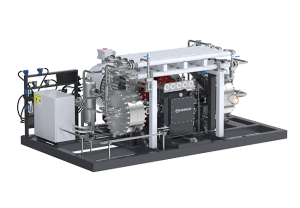

Types of Hydrgen Compressor

The core pressurization equipment for hydrogen refueling stations is the diaphragm compressor. The diaphragm fully isolates the cylinder from the oil chamber, and the diaphragm chamber has excellent sealing properties, ensuring the purity of the hydrogen. The working principle involves the diaphragm performing a reciprocating motion during the oil pressure drop, thereby achieving hydrogen compression.

The diaphragm compressors designed and manufactured by MINNUO are divided into four main types: V, Z, D, and L, with 26 series and nearly 900 products in total.

Features

- Maximum single-unit displacement: 3000 Nm³/h

- Maximum pressure: 100 MPa

- Maximum piston force: 250 kN

- Maximum drive power: 450 kW

- Long lifespan for diaphragms and wear parts

- Single-unit output up to 1000 kg/d

- Low procurement cost, small footprint, low energy consumption

- High operational safety, no risk of gas leakage due to short-lived wear components

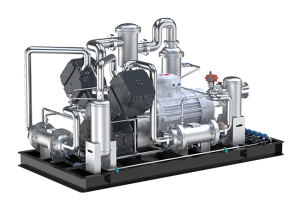

Reciprocating Compressor

The piston-type compressor is driven by a crankshaft and connecting rods, which move the piston up and down to change the cylinder volume, thereby achieving the intake and compression processes. The piston rings serve as seals, and the piston rings inside the cylinder are lubricated by oil.

The piston-type hydrogen compressor manufactured by MINNUO is the most advanced domestically produced reciprocating compressor, incorporating technology from Germany’s MANNES Company. It currently offers four main categories—P, L, D, and M—with 19 series and nearly 700 products.

Features

- Maximum single-unit displacement: 4000 Nm³/min

- Maximum pressure: 20 MPa

- Maximum piston force: 800 kN

- Maximum drive power: 4500 kW

- Control: PLC automatic control

- Drive method: Electric motor

- Cooling method: Air cooling, water cooling, mixed cooling

- Installation type: Container skid-mounted, fixed, soundproof cabin-mounted

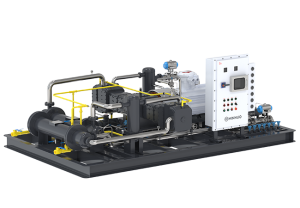

Project Case Study

Case Study – Southeast Asian Metal Processing Plant 500 Nm³/h Hydrogen System

Process Requirements: Continuous supply of 99.99% pure hydrogen at 350 bar.

Solution:

- PSA hydrogen generation unit, utilizing coke oven gas as the raw material, making full use of existing resources to reduce hydrogen production costs.

- Three-stage purification process, including TSA drying, zinc oxide desulfurization, and temperature swing adsorption to remove CO₂, ensuring hydrogen purity meets the requirements.

- Liquid-driven four-stage compressor set to increase hydrogen pressure to 350 bar.

- Skid-mounted design, occupying only 12×3 meters of space, saving space and facilitating installation.

Project Outcome: Installation and commissioning completed in 30 days, reducing hydrogen cost by 37%, bringing significant economic benefits to the customer.

FAQ

A: Yes, all equipment modules are available for individual purchase. You can choose diaphragm-type (≤200 bar) or liquid-driven piston-type (≤450 bar) compressors, and we provide ASME certified pressure vessels and third-party test reports to ensure product quality and safety.

A: The base configuration achieves 99.9% purity, and with the addition of a palladium membrane purification module, it reaches 99.999%, in compliance with GB/T 3634.2 high-purity hydrogen standards. An online mass spectrometer is also provided for real-time purity monitoring.

A: Flow is adjustable in 5-1000+ Nm³/h increments, and pressure options include 15/45/200/350/450 bar in multiple configurations. We can provide customized compression ratios and storage cylinder group solutions based on your needs.

A: Skid-mounted system installation takes ≤7 days on-site. Please prepare a concrete foundation (load ≥5t/m²) and a 380V/50Hz power interface. We provide 3D layout drawings to guide the construction for smooth installation.

A: Standard 2-year full-system warranty, along with remote diagnostic platform support and quarterly preventive maintenance. Key components (such as membrane electrodes, valves) are kept in stock for emergency replacements within 72 hours, ensuring peace of mind.

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168