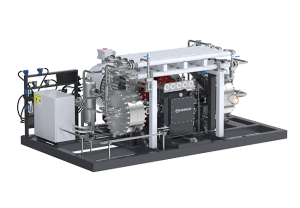

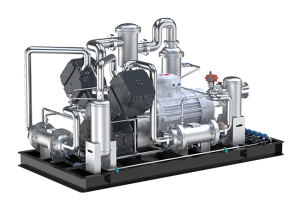

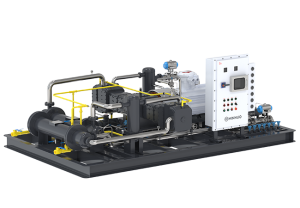

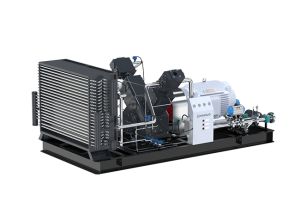

LPG Compressor

MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as liquefied petroleum gas (LPG), propane, butane, and ammonia gas.

With a vertical twin-cylinder structure, oil-free lubrication technology, and international brand core components, our compressors provide strong pressure adaptability and low energy consumption, meeting the stringent demands of factories, docks, gas stations, and the shipping industry.

Working Principle of LPG Compressor

MINNUO LPG compressors achieve efficient media transfer through pressure differential:

MINNUO LPG compressors achieve efficient media transfer through pressure differential:

- Gas Phase Extraction: Extracts gas-phase LPG from the filling tank (or tank truck) to the compressor inlet.

- Pressurization: The gas is compressed and pressurized to 1.6MPa before being delivered to the target storage tank.

- Pressure Differential Formation: The liquid LPG is driven by the pressure differential (0.2-0.3MPa) to flow, completing the unloading or recovery process.

Gas Phase Compression

Pressure Differential Formation

Liquid Medium Transfer

Closed-Loop Circulation

Product Advantages

1.Oil-Free Lubrication Technology to Ensure Media Purity

Packing and cylinders are designed with oil-free lubrication to avoid contamination of gases by oil, ensuring media cleanliness and meeting the strict standards of the chemical industry.

2.International Brand Explosion-Proof Motors with Strong Power

Equipped with explosion-proof motors from brands such as Mitsubishi, ABB, and Siemens, offering stable power output and a 15% increase in energy efficiency, making it suitable for flammable and explosive environments.

3.Patented Sealing Technology for Durability

Carbon fiber piston rings and mesh grid grinding cylinders reduce friction loss, extending the sealing life by 30% and decreasing downtime for maintenance.

4.Compact Vertical Structure to Save Space

The vertical twin-cylinder design reduces volume by 25%, offering lighter weight and lower vibration, making it easier to install and adapt to various spaces.

5.Intelligent Gas Valve and Bearing Systems

Enhanced gas valve wear resistance by 50%, with high-precision bearings ensuring a noise level of ≤75dB, ensuring long-term smooth operation of the equipment.

6.Adaptability to Multiple Scenarios

Covers the full process requirements for truck unloading, gas station filling, railway unloading, and steam recovery, with support for customized pressure and flow configurations.

Application Areas

Scenario | Suitable Models | Typical Use |

Tanker/Tanker Truck Unloading | ZW Series Unloading Compressor | Quick LPG unloading at docks and gas stations |

Cylinder Filling and Recovery | CZW Series Recovery Compressor + Vane Pump | Bottled gas filling, residual liquid recovery at gas stations |

Railway Car Unloading | Reciprocating Compressor | LPG unloading and steam recovery from railway transport |

Booster Station | Turbine Pump + Compressor Combination | Pressure boosting for LPG mixing processes |

Vehicle Gas Station | Vane Pump/Turbine Pump System | Fast LPG refueling for vehicles |

Why Choose MINNUO?

- 1.Industry Experience: Providing LPG compression equipment to over 50 countries, serving leading companies in the oil, chemical, and gas industries.

- 2.Technical Certification: ISO 9001 Quality Management System, CE/ATEX Explosion-Proof Certification.

- 3.Quick Response: Offering 24/7 technical consultation, spare parts supply, and on-site maintenance support.

FAQ

A1:

- Unloading Model (ZW Series): Suitable for high-flow LPG transfer from tank trucks to storage tanks.

- Recovery Model (CZW Series): Designed for fine recovery processing of residual liquid and steam.

A2:

No! The patented carbon fiber piston rings and corrosion-resistant cylinder coatings ensure low friction and high sealing performance, with a design life of 100,000 hours.

A3:All models meet ATEX/IECEx explosion-proof standards, with explosion-proof motors, valves, and other components from international brands.

A4:Yes! Power (7.5-1000kW), flow (0.45-80m³/min), and pressure ranges can be adjusted according to customer requirements.

A5:Routine maintenance is recommended every 2000 operating hours, with key components (gas valves, piston rings) having a lifespan of ≥8000 hours.

Related Solutions

Hydrogen Compressor

Hydrogen Compressor With over 30 years of expertise in hydrogen compression technology, MINNUO is a leading provider in the world. More than 2,000 of our

LPG Compressor

LPG Compressor MINNUO LPG compressors are specifically designed for industrial gas compression scenarios, suitable for the unloading, pressurization, and steam recovery of media such as

CNG Compressor

CNG Compressor The MINNUO CNG compressor is a reciprocating piston-type compression device specifically designed for demanding industrial environments. It is capable of handling multiple mediums,

Ammonia Compressor

Ammonia Compressor MINNUO ammonia compressors are specifically designed for the chemical, refrigeration, and industrial sectors, offering a wide range of compression support for various scenarios

Helium Compressor

Helium Compressor MINNUO helium compressors are specially designed for industrial applications, utilizing reciprocating piston technology to efficiently compress helium gas to high pressures ranging from

CNG Refueling Station Solution

Customized CNG Refueling Station Solutions Comprehensive Coverage from Gas Treatment to Compression and Storage We provide fully integrated CNG refueling systems, including gas drying, compression,

sales2:+86 17506119168

sales2:+86 17506119168