I. Industry Background and Pain Points in Oxygen Demand

The continuous growth of the global population has positioned the aquaculture industry as a core sector for ensuring food security. According to 2024 data from the U.S. Department of Agriculture (USDA), the annual output of U.S. aquaculture exceeds 600,000 tons, with high-value species such as tilapia, salmon, and whiteleg shrimp accounting for over 75%. However, dissolved oxygen (DO) levels— a critical factor limiting aquaculture efficiency— remain a persistent challenge for the industry: when dissolved oxygen in water drops below 5mg/L, fish feeding rates decrease by more than 30% and disease incidence rises by 40%; if DO falls below 3mg/L, large-scale mortality occurs, resulting in single-incident losses of up to several hundred thousand U.S. dollars.

Traditional oxygen supply methods struggle to meet the demands of modern intensive aquaculture. Paddle aeration equipment achieves an oxygen transfer efficiency of less than 15% in ponds deeper than 3 meters, and its high-speed rotation easily damages juvenile fish. Diffused aeration systems improve efficiency to 20% but require complex pipeline installation, with costs exceeding $2,000 per acre. While liquid oxygen enables rapid oxygen supplementation, it is limited by transportation radius (typically no more than 200 miles), requires regular storage tank inspections, and incurs a high single-fill cost of $5,000 per ton, making it economically unviable for long-term use. Particularly during extreme weather events— such as hurricane seasons in the southeastern U.S.— disruptions to liquid oxygen transportation have caused single-day losses exceeding $1 million for shrimp farms in Florida. These pain points have driven the industry to seek more reliable oxygen supply solutions.

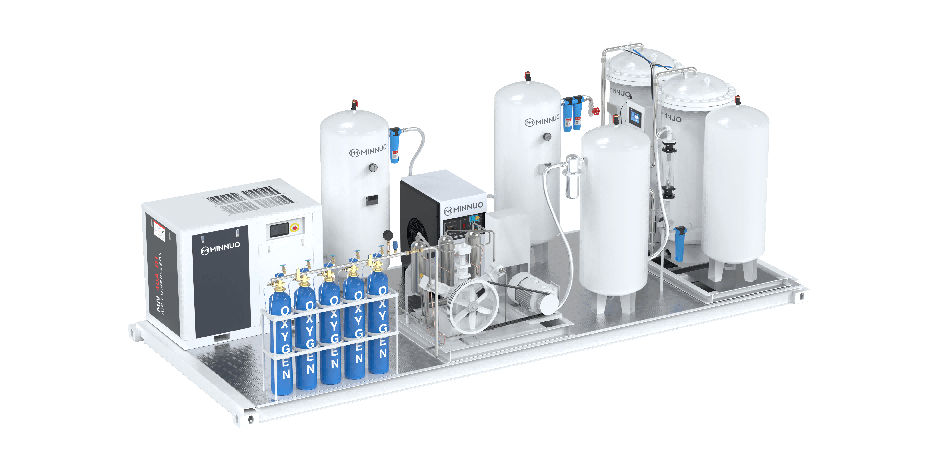

PSA (Pressure Swing Adsorption) oxygen generation technology, leveraging the core advantages of “on-site oxygen production and continuous supply,” has seen rapid adoption in the U.S. aquaculture industry since 2010. According to statistics from the Gas Equipment Manufacturers Association (GAMA), the installed base of PSA oxygen generators in the U.S. aquaculture industry reached 1,200 units in 2023, an increase of 180% compared to 2018. Coverage exceeds 60% in scenarios such as salmon recirculating aquaculture systems (RAS) in California, tilapia ponds in Texas, and shrimp hatcheries in Hawaii. By directly separating oxygen from air, this technology completely eliminates reliance on external gas sources, providing customized oxygen supply solutions for diverse aquaculture scenarios.

II. Working Principle and Technical Characteristics of PSA Oxygen Generators

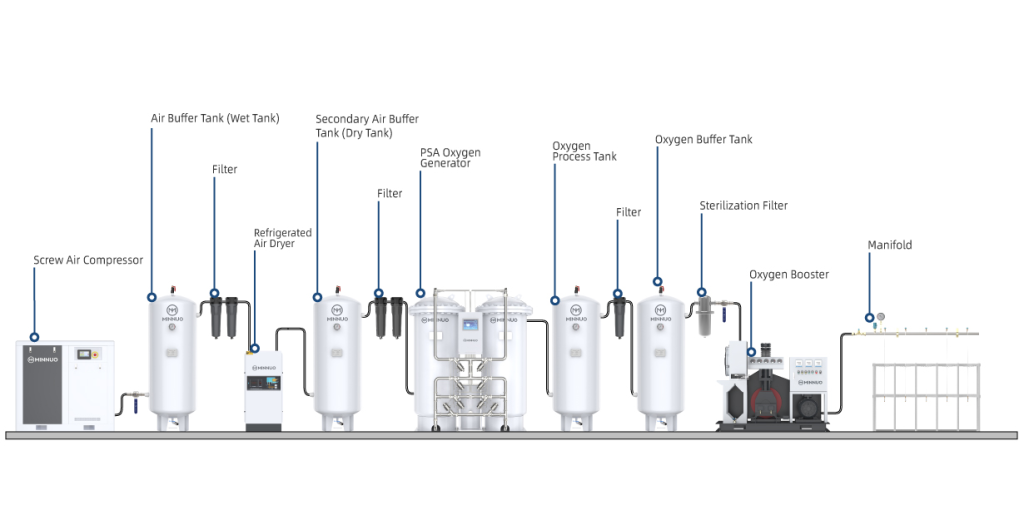

The core of PSA oxygen generation technology lies in the selective adsorption properties of molecular sieves under different pressures to separate oxygen and nitrogen. Mainstream models in the U.S. use 13X zeolite molecular sieves, which have an adsorption capacity for nitrogen more than three times that of oxygen, with optimal adsorption efficiency at pressures ranging from 0.6 to 1.0MPa. The complete workflow consists of four stages, fully automated by a PLC control system, with a cycle time of only 30–120 seconds to ensure continuous oxygen output.

(1) Air Compression and Purification Stage

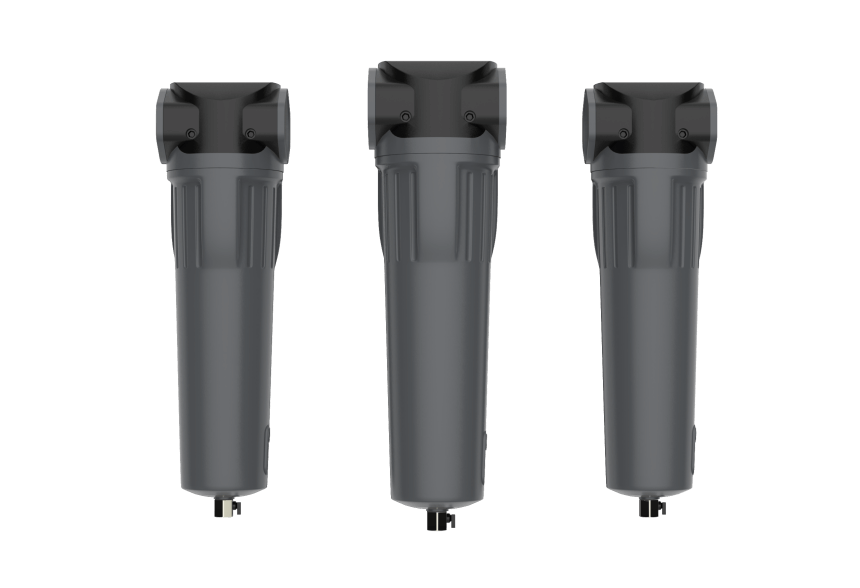

Ambient air first passes through a primary filter (5μm filtration precision) to remove dust, then is compressed to 0.8MPa by a screw air compressor. U.S. brands such as Ingersoll Rand equip their air compressors with variable-frequency technology, which automatically adjusts rotational speed based on oxygen demand, reducing energy consumption by 25% compared to fixed-frequency models. The compressed air then enters a refrigerated dryer to lower the dew point to below -40℃, followed by an activated carbon filter to remove oil mist (residual oil content ≤0.01mg/m³), and finally passes through a precision filter (0.01μm filtration precision). This series of purification steps is critical: if moisture or oil enters the molecular sieve, its adsorption capacity decreases by more than 50%, and its service life shortens from 5 years to 2 years.

(2) Alternating Adsorption and Desorption Stage

The purified compressed air enters one of two adsorption towers. Under pressure, nitrogen is adsorbed by the molecular sieve, while oxygen (90%–95% purity) — the product gas — flows into a buffer tank. When the molecular sieve in the active tower becomes saturated (triggered by a 0.1MPa pressure rise detected by a pressure sensor), the system automatically switches the air flow to the second adsorption tower and depressurizes the saturated tower to atmospheric pressure. During desorption, the adsorbed nitrogen is discharged with the air flow, restoring the molecular sieve’s adsorption capacity for the next cycle. High-end models (e.g., the Oxywise series by Parker Hannifin) adopt a three-tower design, which incorporates a pressure equalization step (transferring 10%–15% of oxygen from the completed adsorption tower to the standby tower), increasing oxygen recovery rate to 90% and reducing energy consumption by 12%.

(3) Oxygen Storage and Delivery Stage

After being tested by an oxygen concentration analyzer (±0.5% precision), the product gas is stored in a 3–5m³ stainless steel buffer tank, where pressure is stabilized at 0.4–0.6MPa. Delivery methods vary by aquaculture scenario: pond aquaculture uses nano-aeration discs (bubble diameter 5–10μm, oxygen transfer efficiency >60%), distributed uniformly via underwater pipelines; recirculating aquaculture systems (RAS) use Venturi injectors, achieving oxygen dissolution efficiency of over 95% at a water flow rate of 1.5m/s; shrimp hatcheries use micro-bubble generators to maintain dissolved oxygen in nursery tanks at 7–8mg/L.

Mainstream PSA oxygen generators in the U.S. market have oxygen production capacities ranging from 5 to 200Nm³/h: 5–20Nm³/h models are suitable for small-to-medium ponds (10–50 acres), 50–100Nm³/h models for RAS facilities, and 200Nm³/h+ models for large-scale shrimp hatcheries. Taking a 10Nm³/h model as an example, it occupies approximately 15㎡ and produces noise ≤75dB, complying with OSHA (Occupational Safety and Health Administration) workshop noise standards, allowing direct installation near aquaculture areas.

III. Application Practices of PSA Oxygen Generators in Different Aquaculture Scenarios

With its flexibility and adaptability, PSA oxygen generation technology has been widely applied across various U.S. aquaculture scenarios, delivering differentiated value in different contexts. Below is an analysis of typical cases:

(1) Intensive Pond Aquaculture: Solving High-Density Oxygen Supply Challenges

Southern Texas is a major tilapia-producing region in the U.S., where local farms widely adopt the “high-density pond + PSA oxygen generation” model, with a stocking density of 30,000 fish per acre (compared to only 15,000 fish per acre in traditional models). Take Sunnydale Farm near Houston as an example: in 2019, the farm introduced two 15Nm³/h PSA oxygen generators, paired with 200 nano-aeration discs (distributed across 10 5-acre ponds). Real-time DO monitoring via sensors triggers automatic oxygen supplementation when dissolved oxygen drops below 5.5mg/L.

Operational data shows that during summer high temperatures (water temperature 32℃), the oxygen generators operate for 12 hours daily, consuming approximately 180kWh of electricity at a cost of $22 (U.S. industrial electricity rate: $0.12/kWh). In contrast, an equivalent-scale operation using liquid oxygen would incur a daily cost of $150. Additionally, the tilapia growth cycle shortened from 8 months to 6 months, survival rate increased from 75% to 92%, annual output per acre rose by 1.2 tons, and the investment payback period was only 14 months. The core advantage of this model lies in breaking the efficiency bottleneck of traditional aeration equipment through precise oxygen supplementation, enabling sustainable operation of high-density aquaculture.

(2) Recirculating Aquaculture Systems (RAS): Ensuring Oxygen Stability in Closed Environments

California is a core salmon aquaculture region in the U.S. Due to freshwater scarcity, 90% of salmon farms use RAS, which achieves over 95% water reuse efficiency. However, closed environments lead to rapid oxygen consumption and increased supplementation difficulty. In 2021, Blue Ocean RAS — a farm in San Francisco Bay — introduced three 50Nm³/h PSA oxygen generators, integrated into its water treatment process: oxygen is injected after the biofilter (enhancing nitrifying bacteria activity, increasing ammonia nitrogen removal rate from 85% to 98%), and secondary oxygen supplementation is performed via injectors at the front end of rearing tanks, maintaining dissolved oxygen at 8–10mg/L.

The system uses a PLC control system by Automation Direct, linking parameters such as dissolved oxygen, water temperature, and pH: when water temperature rises from 15℃ to 18℃ (the upper limit of the optimal growth temperature for salmon), the system automatically increases oxygen output from 30Nm³/h to 45Nm³/h, preventing dissolved oxygen decline as water temperature rises. Operational data shows that the farm’s daily salmon weight gain increased from 1.2g to 1.5g, feed conversion ratio decreased from 1.2 to 1.05, and antibiotic usage reduced by 60% — meeting FDA organic aquaculture standards and enabling a 30% product premium.

(3) Mariculture: Addressing High-Salt, High-Humidity Environmental Challenges

Seawater shrimp hatcheries in Hawaii and Florida have strict requirements for equipment corrosion resistance. Traditional steel oxygen supply equipment has a service life of only 2 years in salt spray environments, while PSA oxygen generators — optimized for materials (e.g., 316L stainless steel compressors, fluorocarbon-coated control panels) — achieve a service life of over 8 years. In 2022, Tropical Shrimp Hatchery in Miami introduced four 10Nm³/h PSA oxygen generators to supply oxygen to 200 nursery tanks (20㎡ each). Micro-bubble generators produce bubbles with a diameter of 2–5μm, ensuring dissolved oxygen levels (6–7mg/L) meet the needs of shrimp larvae (mysis stage).

The hatchery specifically designed an emergency power supply system: in the event of grid failure due to hurricanes, a diesel generator starts within 10 seconds to maintain oxygen generator operation. During Hurricane Ian in 2023, the hatchery achieved a 90% shrimp larvae survival rate thanks to the continuous oxygen supply from PSA generators, while nearby shrimp farms using liquid oxygen suffered survival rates of less than 30% due to transportation disruptions. Additionally, nitrogen — a byproduct of the oxygen generators (purity >98%) — is used for water disinfection, replacing traditional chlorine-based agents to reduce irritation to shrimp larvae and shortening the nursery cycle by 3 days.

(4) High-Value Species Aquaculture: Precision Regulation to Improve Quality

U.S. sturgeon aquaculture (primarily for caviar production) has strict dissolved oxygen requirements: when DO drops below 7mg/L, caviar grain size becomes uneven; below 6mg/L, yolk accumulation is affected. Sturgeon Caviar Farm in Idaho uses two 20Nm³/h PSA oxygen generators, with real-time oxygen output adjustment via online DO monitors (±0.1mg/L precision), maintaining dissolved oxygen in rearing tanks at 7.5–8mg/L.

The system is also linked to a water temperature control system: when winter water temperature drops from 12℃ to 8℃, fish metabolic rate decreases by 40%, and the system automatically reduces oxygen output from 15Nm³/h to 10Nm³/h to avoid energy waste. Practical results show that the farm’s caviar grade (classified as Grade A, B, or C per international standards) reached 85% Grade A — a 30% increase compared to traditional oxygen supply methods — with a market price of $5,000 per kilogram, delivering significant economic benefits.

IV. Key Points for Selection, Installation, and Maintenance of PSA Oxygen Generators

In the U.S. aquaculture industry, the successful application of PSA oxygen generators relies on scientific selection, standardized installation, and refined maintenance. Below is a full-process guide based on U.S. industry standards and practical cases:

(1) Selection Calculation: Precise Matching Based on Aquaculture Scenarios

Selection must comprehensively consider water volume, stocking density, species characteristics, and ambient temperature. The core formula is:

Oxygen Demand (Nm³/h) = Water Volume (m³) × DO Difference (mg/L) × Safety Factor / 60

Where:

– DO Difference = Target DO Value – Natural DO Value

– Safety Factor = 1.2–1.5 (use the upper limit in high-temperature seasons)

For example, in a California salmon RAS farm:

– Rearing tank volume = 500m³

– Target DO = 8mg/L

– Natural DO = 4mg/L

– Safety Factor = 1.5

Oxygen Demand = 500 × (8–4) × 1.5 / 60 = 50Nm³/h

Thus, a 50Nm³/h model is selected (with a 20% margin reserved). For pond aquaculture, additional factors such as wind and water flow must be considered: in windy areas of the Texas Plains (average annual wind speed 3m/s), an extra 10% oxygen supply is required to prevent surface DO from being dispersed by wind.

Additionally, oxygen purity selection matters: 90% purity suffices for general pond aquaculture, while 93%–95% purity is required for shrimp hatcheries and high-value species farming. If purity drops below 85%, check for molecular sieve aging (per ANSI standards, molecular sieves must be tested for adsorption capacity after 3 years of use and replaced if capacity declines by over 20%).

(2) Installation Standards: Compliance with U.S. Safety and Environmental Standards

Installation sites must meet three requirements:

- Good ventilation (air exchange rate ≥10 times per hour) to prevent nitrogen accumulation (nitrogen concentration >8% causes suffocation);

- Distance from water sources (≥5m from pond edges) to avoid equipment moisture damage;

- Floor load capacity ≥500kg/㎡ (including auxiliary equipment such as air compressors and buffer tanks).

Pipeline installation must comply with ASME B31.3 standards:

– Oxygen pipelines use 316L stainless steel;

– Pipe diameter is determined by flow rate (e.g., DN50 for 50Nm³/h models);

– Bend radius ≥3 times the pipe diameter to avoid turbulence-induced oxygen loss.

After installation, an airtightness test is required: charge with 0.8MPa nitrogen and maintain pressure for 24 hours; a pressure drop ≤0.02MPa is considered qualified.

Electrical systems must comply with NFPA 70 (National Electrical Code):

– Explosion-proof design (Class I, Division 2 rating);

– Grounding resistance ≤4Ω;

– Control panels must be placed ≥10m away from aquaculture areas to prevent circuit damage from moisture.

For example, shrimp hatcheries in Hawaii install additional salt spray filters (replaced every 3 months) during installation, effectively extending the service life of electrical components to over 5 years.

(3) Maintenance Management: Key Measures to Extend Equipment Life

Daily maintenance should follow a “daily inspection, weekly maintenance, annual overhaul” system:

– **Daily Inspection**: Check oxygen concentration (read via online analyzer; alarm if below 5% of the set value), pressure (buffer tank pressure should stabilize at 0.4–0.6MPa), and temperature (air compressor discharge temperature ≤100℃);

– **Weekly Maintenance**: Clean air filters (backflush with compressed air; replace filters if pressure difference exceeds 0.05MPa);

– **Annual Overhaul**: Replace molecular sieves (if used for over 5 years), test solenoid valve response time (should be ≤0.5 seconds), and calibrate sensors (re-calibrate if error exceeds 1%).

Some U.S. farms also use remote monitoring systems (e.g., via SCADA platforms) to transmit real-time equipment operating data to the cloud. For instance, when a tilapia farm in Texas experienced a drop in oxygen concentration to 88% in its PSA oxygen generator, the system automatically sent an SMS alert to technicians, who arrived on-site within 2 hours, identified and replaced a clogged molecular sieve, and avoided losses.

Additionally, lubricating oil replacement must strictly follow manufacturer requirements: screw air compressors typically require oil changes every 2,000 hours using dedicated lubricants (e.g., Shell Corena S4 R68). Using low-quality oil accelerates compressor wear and increases maintenance costs by 30%.

V. Industry Application Trends and Technical Innovation Directions

As the U.S. aquaculture industry transitions toward “intensification, intelligence, and sustainability,” PSA oxygen generation technology is evolving toward higher efficiency, lower energy consumption, and greater intelligence. The 2024 *Aquaculture Technology Roadmap* released by the U.S. Department of Energy (DOE) sets targets for PSA oxygen generators over the next 5 years: reducing energy consumption from the current 0.4kWh/Nm³ to 0.3kWh/Nm³ and increasing oxygen recovery rate from 90% to 95%.

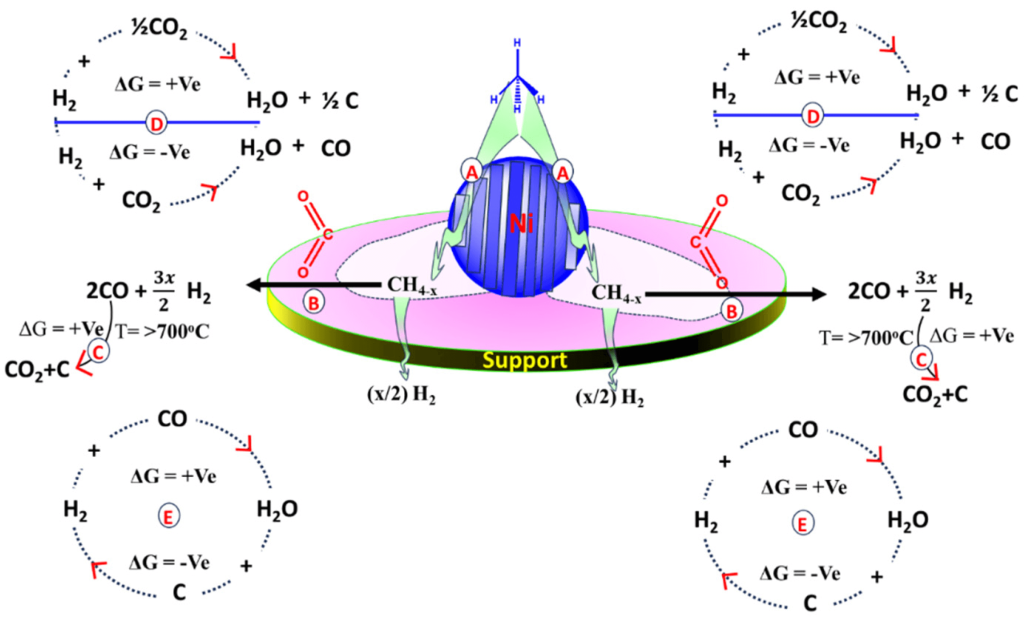

(1) New Material Applications: Enhancing Molecular Sieve Performance

The Oak Ridge National Laboratory (ORNL) is developing nano-composite molecular sieves by doping 13X zeolite with 2% graphene. This modification increases nitrogen adsorption rate by 40%, adsorption capacity by 25%, and reduces regeneration temperature by 50℃, significantly extending service life to 8 years. Pilot testing of this new material in Oregon salmon farms in 2023 showed a 18% reduction in oxygen generator energy consumption and stable oxygen purity above 95%.

(2) Intelligent Upgrades: AI-Driven Precision Control

Parker has launched a new generation of PSA oxygen generators integrated with AI algorithms, which predict oxygen demand based on historical data (e.g., 3 years of DO changes, water temperature fluctuations, and feeding amounts). For example, based on the feeding schedule (9:00 and 15:00 daily), the system increases oxygen supply by 20% one hour in advance to match the high oxygen consumption of fish after feeding. Application in a trout farm in Washington State showed that this predictive control reduced energy consumption by 15% and limited DO fluctuations to ±0.2mg/L.

(3) Modular Design: Adapting to Small-Scale Aquaculture

To meet the needs of family farms and small hatcheries, Atlas Copco has launched modular PSA oxygen generators (5–10Nm³/h capacity) with containerized design (dimensions: 2.4m×1.2m×1.8m). These units can be quickly hoisted into place, shortening installation time from the traditional 2 weeks to 3 days. The models also support solar power supply: a small shrimp farm in Arizona paired its system with 5kW solar panels, achieving 70% self-sufficiency in energy and saving over $8,000 in annual electricity costs.

(4) Multi-Technology Integration: Building Circular Ecosystems

PSA oxygen generators are being integrated with carbon capture and water purification technologies to create sustainable aquaculture models. Cargill’s pilot base in Iowa uses nitrogen (a byproduct of oxygen generators) for algae cultivation (as a carbon source), and the algae are then used as fish feed — forming an “oxygen-nitrogen-feed” circular chain. This model reduces aquaculture costs by 20% and carbon emissions by 35%, complying with EPA “green aquaculture” certification standards and promising widespread adoption across the U.S.

VI. Conclusions and Outlook

With its core advantages of “on-site oxygen production, high efficiency, energy savings, and reliability,” PSA oxygen generators have become a key technology for breaking oxygen supply bottlenecks in the U.S. aquaculture industry. From precision control in California salmon RAS farms to disaster resilience in Florida shrimp hatcheries and quality improvement in Idaho sturgeon aquaculture, their application scenarios continue to expand, delivering significant economic and environmental benefits. According to statistics from the American Aquaculture Society (AAAS), farms using PSA oxygen generators achieve an average 25% increase in profitability, 30% reduction in energy consumption, and 50% decrease in antibiotic usage.

In the future, with the integration of new materials, AI, and renewable energy technologies, PSA oxygen generators will move toward greater “intelligence, low carbon emissions, and flexibility.” For U.S. aquaculture practitioners, selecting a suitable PSA oxygen generation system not only improves production efficiency but also supports the achievement of “sustainable aquaculture” goals. While meeting regulatory requirements from agencies such as the FDA and USDA, it also helps seize opportunities in the high-end aquatic products market. As a senior PSA gas equipment engineer, I firmly believe that PSA oxygen generation technology will continue to drive the transformation and upgrading of the global aquaculture industry, providing a “Chinese solution” for the sustainable development of global aquaculture.

sales2:+86 17506119168

sales2:+86 17506119168