We provided Artizan Coffee Company with 10 custom-designed 20 cubic nitrogen generators, equipped with 22kW air compressors, 600L air tanks, and an intelligent PLC control system, ensuring that nitrogen purity reaches 99.99%. Our comprehensive installation and after-sales support ensured stable operation of the equipment. The client expressed high satisfaction with both the equipment and services and has stated they are willing to recommend our products to other coffee roasters.

Basic Information

Artizan Coffee Company is a U.S.-based coffee roasting company. Their coffee packaging machines required an upgrade to nitrogen generators, with the following requirements:

- Increase nitrogen output by at least four times compared to the existing nitrogen generators.

- Achieve nitrogen purity of 99.99%.

- The equipment must support their current coffee packaging machines as well as future business expansion.

Technical Solution

Initial Plan

After confirming the requirements, we communicated with the client’s coffee machine equipment supplier. Based on their recommendation, a 5 cubic meter nitrogen generator was considered sufficient, but the client felt the output was still too low. Given the client’s need for a higher nitrogen production rate, we proposed the following initial plan:

- 15 units of 10 cubic nitrogen generators

- 7.5kW air compressors

- Quotation: $7,950

Upgraded Plan

After reviewing the initial quotation, the client stated that the 10 cubic nitrogen generators would still not meet their needs and requested an upgrade to 20 cubic nitrogen generators. We proposed a 15kW air compressor as the initial configuration, but the client asked for a larger compressor to provide more air supply. We optimized the solution as follows:

- 10 units of 20 cubic nitrogen generators

- 22kW air compressors

- Quotation: $11,800

Comprehensive Equipment Optimization

We provided a high-end component configuration for the client, including:

- Air Compressor Upgrade: We supplied permanent magnet variable frequency air compressors, equipped with permanent magnet variable frequency IP54 inverters from Inovance, which saved energy and achieved approximately 30% energy savings compared to traditional compressors.

- Air Tank Configuration: To ensure stable air supply, we configured 600L air tanks for the client and added air supply branch pipelines to provide gas to another unit. This design further improved equipment flexibility and gas source stability.

- Intelligent Control: Our nitrogen generators are equipped with an intelligent PLC control system that supports remote monitoring and fault diagnosis. The client can monitor equipment status and access real-time data, enhancing production efficiency and equipment reliability.

Service Guarantee

After-Sales Service

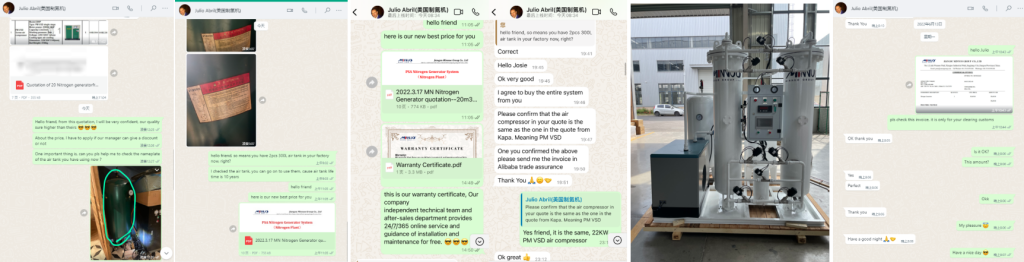

- Installation and Commissioning Support: After equipment delivery, we provided the client with detailed installation and commissioning guides and assisted with the installation process via remote video conferencing.

- Equipment Operation Tracking: We created a communication group to monitor the equipment’s operation and provided 24/7 online support to help the client resolve any technical issues.

After-Sales Follow-Up

- Regular Inspections and Debugging: After installation, we followed up with the client to ensure equipment stability, nitrogen purity of 99.99%, and that the gas output met their needs.

- Customer Satisfaction Survey: We conducted a satisfaction survey a year later, with excellent feedback received from the client.

Customer Feedback and Results

The client expressed high satisfaction with our service and products:

- Equipment Stability: The client reported that the equipment operates very stably, with nitrogen purity consistently at 99.99%, significantly improving production efficiency.

- After-Sales Service: The client especially appreciated our full support throughout the equipment delivery process, including installation, commissioning, and ongoing technical follow-up, considering this one of the key reasons for choosing MINNUO.

- Equipment Recommendation: The client stated they would recommend our equipment to other coffee roasters in the U.S. and are willing to show potential clients how the equipment operates. They even invited other customers to visit their facility to see the equipment in operation and took photos.

Conclusion

Through this collaboration, MINNUO successfully enhanced Artizan Coffee Company’s nitrogen generation capacity and provided strong support for their business expansion. We look forward to working with more international clients to drive industry growth.

sales2:+86 17506119168

sales2:+86 17506119168