Nitrogen is a crucial gas widely used in industries, medical fields, and laboratories. Common nitrogen, obtained through air separation technology, is primarily used for inert protection, freezing, and fire extinguishing. In many applications, nitrogen purity is a critical parameter because different purity levels suit various needs and situations. Therefore, producing high-purity nitrogen is an essential process.

Standards for High-Purity Nitrogen

Nitrogen, comprising about 78% of the air, can be further purified after air separation to meet specific purity requirements. The purity levels of nitrogen are typically classified according to international standards, based on the concentration of impurities.

Here are the main purity levels of nitrogen:

Industrial Grade (Common Nitrogen): With a purity of 99.5%, this grade is suitable for non-critical industrial environments.

- Pure Nitrogen: At 99.99% purity, it is used in the food and beverage industry.

- High Purity Nitrogen: With a 99.998% purity level, this grade is used in the pharmaceutical and electronics manufacturing industries.

- Ultra High Purity Nitrogen: This grade boasts nitrogen content between 99.9999% and 99.99999%, with impurity levels typically measured in parts per billion (ppb). Ultra-high-purity nitrogen is primarily used in semiconductor manufacturing and pharmaceutical production.

Methods for Producing Nitrogen

Common methods for producing nitrogen with standard purity include membrane nitrogen generation, cryogenic air separation, and PSA (Pressure Swing Adsorption) nitrogen generation.

High Purity Nitrogen Production Process

The methods mentioned above can produce nitrogen with a purity of up to 99.998%. For users requiring nitrogen purity above 99.998% and having large gas consumption needs, a cost-effective approach involves using a nitrogen generator to produce common nitrogen, followed by purification equipment. This method reduces both initial equipment investment and operating costs. Two common purification methods are hydrogen purification and carbon purification:

Nitrogen Generator + Hydrogen Purification Equipment

In this method, a nitrogen generator first produces common nitrogen. Under a catalyst, trace oxygen in the nitrogen reacts with hydrogen to form water, which is then removed along with other impurities like carbon dioxide and dust through an adsorption drying unit, resulting in high purity 99.9995% nitrogen.

Equipment Features:

1.Uses world-leading, high-efficiency deoxygenation catalyst with excellent activity.

2.Employs a heat exchanger to lower the temperature of the deoxygenated gas, eliminating the need for cooling water.

3.Fully automatic control with an optional mass flow controller for automatic hydrogen addition.

4.Low regeneration gas discharge, saving energy.

Nitrogen Generator + Carbon Purification Equipment

This method uses a carbon-based catalyst. Trace oxygen in the nitrogen reacts with carbon, removing the oxygen. The resulting gas then passes through an adsorption drying unit to remove CO2 and dust, yielding high-purity nitrogen.

Equipment Features:

1.Provides safe and stable gas production with nitrogen purity consistently above 99.9995%.

2.Dual-tower switching allows for desiccant replacement or major maintenance without shutting down.

3.Automatic control of the drying tower, with adsorber switching managed by a PC on a set schedule.

Applications

High-purity nitrogen, with a purity exceeding 99.998%, finds extensive applications across various fields due to its exceptional purity and stability.

Electronics Industry

High-purity nitrogen plays a crucial role in the electronics industry, particularly in semiconductor manufacturing. It is used as a carrier and protective gas in processes like chemical vapor deposition to minimize metal contamination and ensure the quality of semiconductor chips. Additionally, high-purity nitrogen supports clean environments and stable conditions in photolithography, etching, and thin-film deposition equipment. Ultra-high-purity nitrogen is also essential in the electronic semiconductor industry.

Medical Field

In the medical field, high-purity nitrogen is indispensable. It is commonly used as an anesthetic gas in operating rooms to anesthetize patients. Moreover, it is vital in gas delivery systems, helping maintain the proper functioning of ventilators and anesthesia machines.

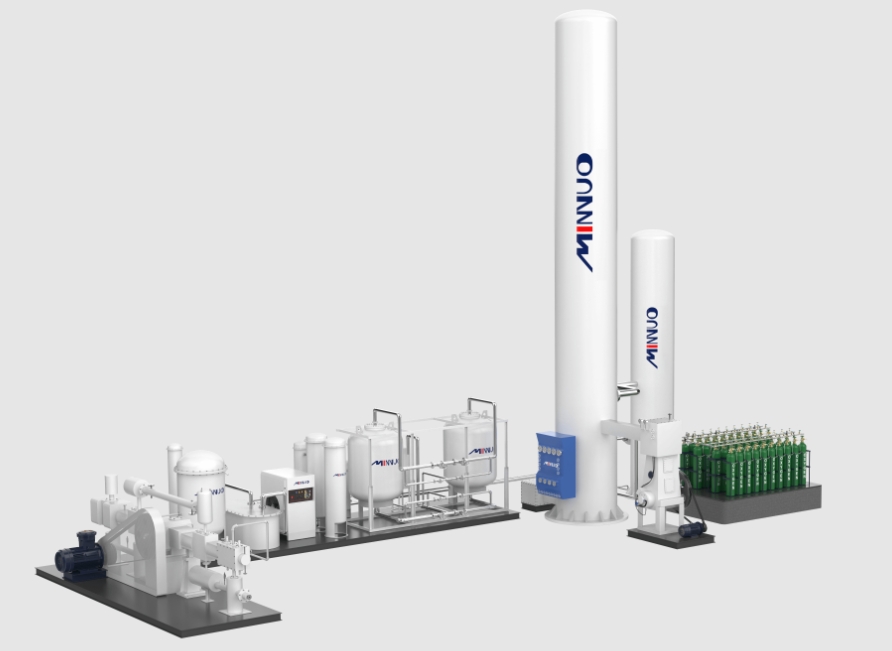

Minnuo Nitrogen Generator

Minnuo, as a high purity nitrogen generator manufacturer and supplier, we specialize in providing nitrogen generator of various purity levels. If you have questions about selecting the right nitrogen purity and equipment, our engineers are ready to assist you with professional advice. Plus, you can receive a discounted price on nitrogen machine!

sales2:+86 17506119168

sales2:+86 17506119168