Dissolved oxygen isn’t just another parameter to monitor in aquaculture—it is the very currency of life in your ponds, tanks, and raceways. While traditional aeration methods have served the industry for decades, they often hit a ceiling in efficiency and control, especially in high-density or intensive farming operations. The critical question for modern fish farmers is no longer just if to oxygenate, but how to do it with maximum reliability and precision. This is where on-site oxygen generators are fundamentally changing the game, offering a level of environmental control that can dramatically boost yield, health, and overall farm profitability.

The Critical Role of Oxygen in Aquaculture

At its core, successful aquaculture hinges on maintaining water quality, and oxygen is its most critical component. Fish and other aquatic species breathe oxygen dissolved in water through their gills. Unlike terrestrial animals, they cannot escape to a better environment when conditions deteriorate. Every aspect of their metabolism—growth, feed conversion, immune response, and reproduction—is directly tied to the availability of dissolved oxygen.

Traditional methods like paddlewheel aerators, diffused air systems, or surface agitators work by churning the water to increase its contact with the atmosphere. While effective to a point, their efficiency is inherently limited by atmospheric pressure, water temperature, and humidity. On a hot, humid, still day when oxygen demand is highest, their ability to transfer oxygen is at its lowest. This creates a dangerous bottleneck, capping stocking densities and leaving operations vulnerable to sudden crashes.

The evolution towards pure oxygen injection represents a paradigm shift. Instead of relying on the slow, passive diffusion of atmospheric air (which is only 21% oxygen), farmers can now introduce streams of high-purity oxygen (90-95%) directly into the water column. This delivers a powerful, on-demand tool to manage the single most important factor in their stock’s well-being.

Why Dissolved Oxygen is the #1 Priority for Fish Farmers

Understanding the consequences of oxygen fluctuation is key to appreciating the value of precise control.

The Impact of Low DO on Fish Health and Growth

When dissolved oxygen (DO) levels drop below optimal ranges, fish experience immediate stress. Their first response is to reduce or cease feeding, directly halting growth. Energy that should go towards building mass is diverted to basic survival. Prolonged exposure to even moderately low oxygen levels results in stunted growth, poor Feed Conversion Ratios (FCR), and weakened constitutions, making them susceptible to secondary issues.

Consequences of Oxygen Depletion: From Disease to Mass Mortality

A rapid drop in DO levels is a silent emergency. Fish will crowd near water inlets or the surface, gasping for air. Beyond a critical threshold, oxygen debt leads to suffocation and mass mortality, which can wipe out an entire crop within hours. More insidiously, chronically low oxygen creates an ideal environment for harmful anaerobic bacteria to thrive, increases the toxicity of ammonia, and suppresses the immune system of the stock, leading to persistent disease outbreaks that are costly to treat.

Target DO Levels for Different Species and Life Stages

Optimal DO levels are not a one-size-fits-all target. They vary significantly:

- Cold-water species like Trout and Salmon: Require high levels, often above 6 mg/L, and ideally closer to 8-10 mg/L for optimal growth, especially in dense pens.

- Warm-water species like Tilapia and Catfish: Can tolerate slightly lower levels (5-7 mg/L), but still benefit greatly from maintained saturation.

- Shrimp and Prawns: Require careful management, with ideal levels above 5 mg/L. Larvae and post-larvae stages in hatcheries are particularly sensitive and demand near-saturation levels.

- High-stress periods: During handling, grading, vaccination, or temperature spikes, oxygen demand can skyrocket. The ability to temporarily “super-oxygenate” the water is a powerful tool to prevent losses.

Traditional Aeration vs. Pure Oxygen Injection: A Game Changer

To understand the revolution, one must compare the old standard with the new capability.

Limitations of Mechanical Aeration Methods

Paddlewheels and blowers are limited by the laws of physics. They can only increase oxygen up to the saturation point of water in contact with air, which decreases as water temperature rises. Their energy efficiency drops dramatically as they try to push against this saturation ceiling. They are excellent for general circulation and baseline aeration but are often inadequate as the sole oxygen source for intensive, high-biomass systems.

How Pure Oxygen Injection Works and Its Superior Efficiency

Pure oxygen systems bypass atmospheric limitations entirely. By injecting gas that is 90-95% oxygen, the driving force for dissolution is over four times greater than with air. This allows for extremely efficient transfer using devices like:

- Oxygen Cones (Degassing Columns): Water flows down a column while oxygen is bubbled upwards, allowing for very high dissolution efficiency (often over 90%).

- U-Tubes and Deep Diffusion: Injecting oxygen at depth increases contact time and pressure, further enhancing transfer.

- Nano-bubble Diffusers: Create tiny, long-lasting bubbles with a massive surface area for efficient dissolution directly in ponds or tanks.

This method delivers oxygen precisely where and when it’s needed, without the massive energy expenditure of churning entire water bodies.

Key Applications in Modern Aquaculture

This precision enables advanced farming techniques:

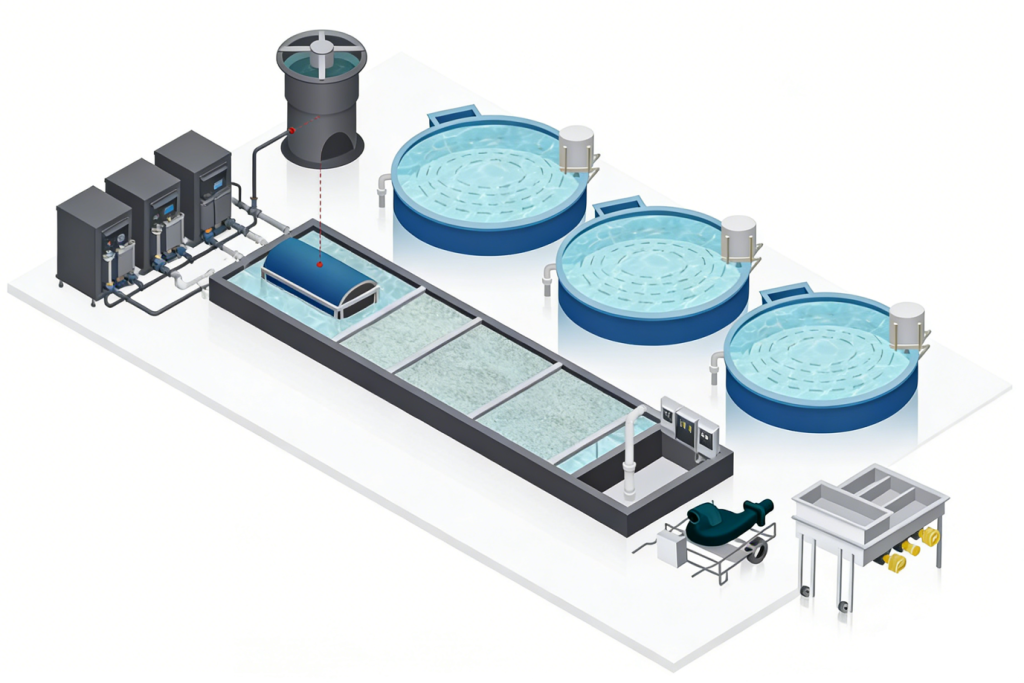

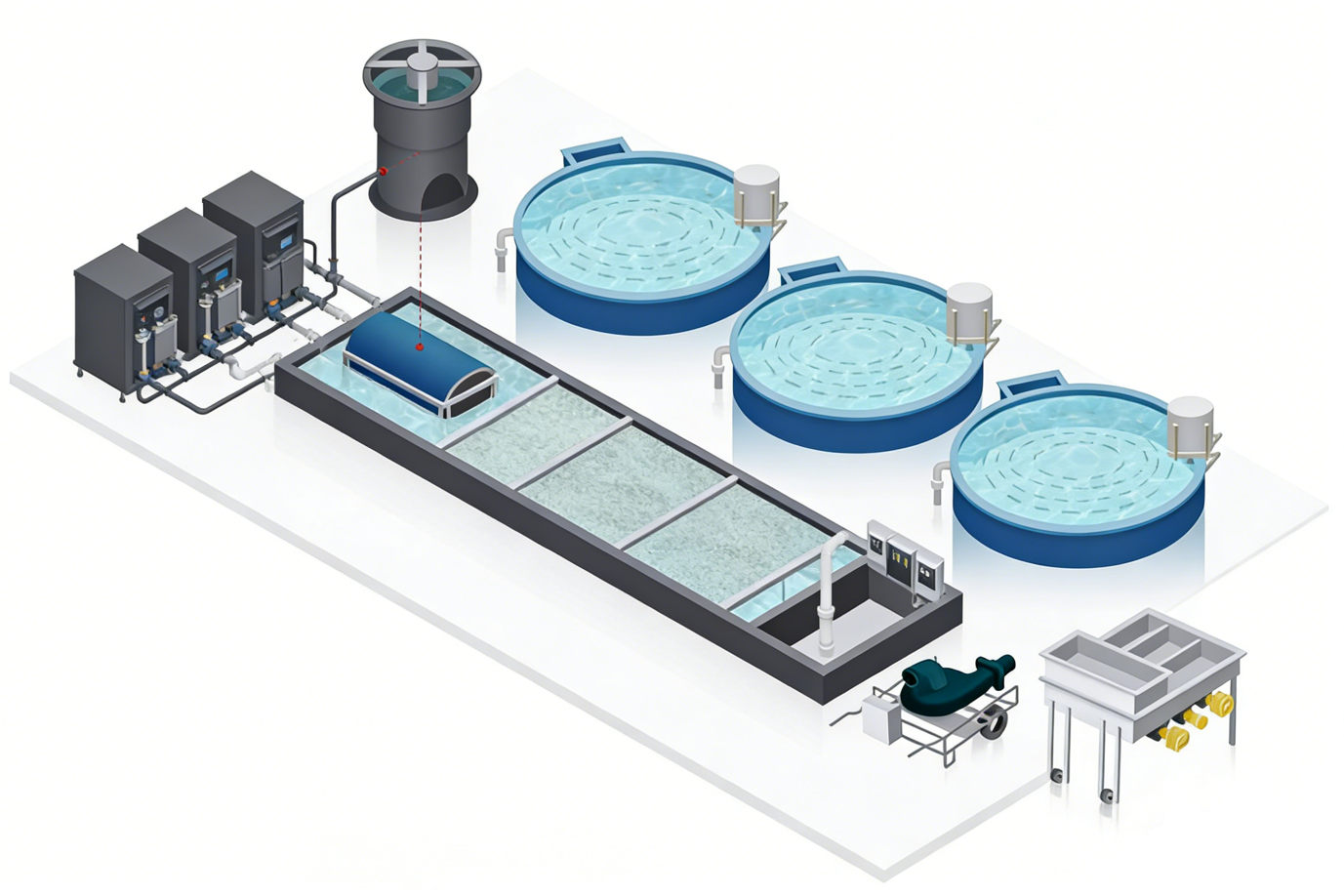

- Fish Hatcheries and Larval Rearing: Fingerlings and larvae have minimal energy reserves. A stable, high-DO environment is non-negotiable for survival and strong early development. Pure oxygen systems provide the critical stability that mechanical aeration cannot guarantee in sensitive hatchery tanks.

- High-Density Grow-Out Tanks and Raceways: In Recirculating Aquaculture Systems (RAS) or flow-through raceways, biomass densities are extremely high. Pure oxygen is not an option but a requirement to sustain life and achieve commercial viability. It is the backbone of these intensive production models.

- Live Fish Transport: Whether in well-boats or hauling tanks, maintaining DO during transport is paramount. On-board or truck-mounted oxygen generators ensure stock arrives alive and healthy, expanding market reach.

- Emergency Oxygenation: During power failures (when aerators stop) or algal die-offs (which consume oxygen), a backup oxygen generator can be the difference between a minor incident and a catastrophic loss.

How On-Site Oxygen Generators Work for Aquaculture

The heart of this system is the oxygen generator itself, most commonly using Pressure Swing Adsorption (PSA) technology.

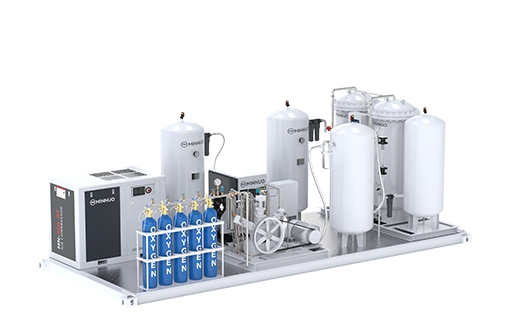

Core Technology: Pressure Swing Adsorption (PSA) Explained Simply

A PSA oxygen generator for aquaculture works by separating oxygen from compressed air. Ambient air is drawn in, filtered, and compressed. This compressed air is then passed through a vessel containing a specialized material called a Zeolite Molecular Sieve. This sieve has a preferential affinity for adsorbing nitrogen and other trace gases under pressure, allowing a stream of high-purity oxygen (typically 90-93% for aquaculture) to pass through. The system uses two such vessels: while one is producing oxygen, the other is depressurizing to release the captured nitrogen, ensuring a continuous, uninterrupted flow of gas. This technology is renowned for its reliability, simplicity, and low operating cost.

Key Components of an Aquaculture Oxygenation System

A complete system is more than just the generator:

- Air Compressor and Dryer: Provides clean, dry, oil-free compressed air—the essential feedstock for the PSA process.

- PSA Oxygen Generator: The core unit producing the oxygen stream.

- Oxygen Buffer Tank: A storage vessel that smooths out demand fluctuations and provides a critical reserve.

- Oxygen Dissolution Device: The interface with the water. Choosing the right device is crucial for efficiency. Common devices and their ideal application scenarios include:

- Oxygen Cones (Degassing Columns): Achieve over 90% dissolution efficiency. Best for Recirculating Aquaculture Systems (RAS), hatcheries, and high-density tanks/raceways where precise control and high oxygen utilization are needed.

- U-Tubes / Deep Diffusion: Inject oxygen at depth, using water pressure to enhance dissolution. Best for deep-water cages, large deep ponds, or situations requiring bottom-water oxygenation.

- Nano-bubble Diffusers: Create microbubbles with long dwell times, improving overall water redox potential. Best for large earthen ponds or lined ponds, enabling uniform whole-water-column oxygenation and improving substrate conditions.

- Control Panel and Monitoring: Integrated sensors for dissolved oxygen, flow meters, and automated controls that adjust oxygen output based on real-time demand, creating a “set-and-forget” environment.

Advantages Over Liquid Oxygen (LOX) Tanks

Many farms initially consider liquid oxygen tanks. However, on-site generation offers compelling advantages:

- Cost Control & Predictability: Eliminates the volatile and often high monthly rental and delivery charges from gas companies. Operating costs are primarily electricity and routine maintenance.

- Supply Security and Independence: No risk of delivery delays, shortages, or logistical hiccups. You produce what you need, on-demand, 24/7.

- Ideal for Remote Locations: Farms far from industrial gas suppliers gain complete independence, making expansion into new areas feasible.

- Safety: Removes the hazards associated with handling and storing cryogenic liquids at -183°C.

Key Considerations When Choosing an Aquaculture Oxygen Generator

Selecting the right system requires a clear understanding of your operation’s needs.

Determining Your Oxygen Demand (kg/h or L/h)

This is the most critical step. Demand is based on total biomass, the species-specific oxygen consumption rate (which changes with size and temperature), and the target DO level. A reputable supplier will help you model this, but understanding a basic estimation logic is helpful for initial planning:

Simplified Estimation Formula: Hourly Oxygen Demand ≈ Total Biomass × Specific Oxygen Consumption Rate × Safety Factor

- Example: A pond with 10 tons of Tilapia at 28°C water temperature has a consumption rate of approximately 300 mg/kg/h. Basic demand: 10,000 kg × 0.3 g/kg/h = 3,000 g/h = 3 kg/h.

- Safety Factor: To account for peak feeding times, nighttime (no photosynthesis), etc., a 30%-50% redundancy is often recommended. Thus, this system might require a generator with a capacity of roughly 4 to 4.5 kg/h.

Understanding your needs in kilograms per hour is the first step to proper sizing. Oversizing wastes capital; undersizing risks your stock.

Purity Requirements: Is 90% or 93% Enough?

For aquaculture oxygen applications, purities between 90% and 95% are standard and perfectly adequate. The pursuit of medical-grade oxygen (99+%) is unnecessary and significantly increases cost and energy consumption. The efficiency gain over air is already massive at 90% purity.

Reliability and Backup Systems for Uninterrupted Supply

Oxygen is life support. The system’s reliability is paramount. Look for robust construction, quality components (especially air compressors and valves), and a design with redundancy where possible. A backup power source (generator) for the oxygen system is a wise investment. Additionally, an adequately sized oxygen buffer tank acts as a “battery,” providing crucial time to address any mechanical issues without immediate risk to the fish.

Aquaculture-Specific Maintenance Focus: The farm environment poses unique challenges for equipment.

- Corrosion Protection: For coastal farms or high-humidity areas, selecting main and peripheral equipment with high-standard anti-corrosion coatings (e.g., marine-grade paint) is critical to prevent salt spray and moisture damage.

- Enhanced Air Intake Filtration: Farm air can contain more dust, ammonia, or moisture. Air intake filters for outdoor units need more frequent inspection and replacement, and consider adding a pre-filtration stage to protect the molecular sieve and compressor.

- Regular Sensor Calibration: Moisture and biofilms can affect dissolved oxygen probe accuracy, necessitating a more frequent calibration schedule than in typical industrial settings.

FAQ

Q1: What is the typical cost of setting up an on-site oxygen system for a medium-sized farm?

A1: Investment varies widely based on required oxygen capacity (kg/hour) and system complexity. It can range from a significant but manageable capital outlay for a modular system to a major project for a large RAS facility. The key financial perspective is to view it through Total Cost of Ownership (TCO). While the initial investment may be higher than paddlewheels, the elimination of ongoing liquid oxygen bills, combined with the tangible returns from increased survival rates, higher stocking densities, faster growth, and better FCR, typically results in a compelling return on investment (ROI) within a few years.

Q2: Can I use the same oxygen generator for both my fish ponds and a hatchery?

A2: Yes, absolutely. This is one of the strengths of a centralized on-site system. The oxygen produced can be piped to multiple points of use across the farm. However, the system must be designed and sized to meet the peak simultaneous demand of all connected facilities (hatchery, grow-out ponds, harvest station, etc.). Proper piping, pressure regulation, and control valves are essential for safe and efficient distribution.

Q3: How much can I increase my stocking density with pure oxygen?

A3: There is no universal multiplier, as it depends on species, system design (e.g., water exchange rates in ponds vs. RAS), and management. However, the shift from aeration-limited to oxygen-secured environments commonly allows farmers to safely increase densities by 30% to over 100% in controlled systems like tanks or raceways. In ponds, it provides the critical safety margin to support higher feeding rates and biomass, especially during vulnerable night-time hours when photosynthesis stops.

Q4: What maintenance does an aquaculture oxygen generator require?

A4: PSA oxygen generators are known for low maintenance. Essential routine tasks include:

- Replacing intake air filters every 1-3 months (more frequently in coastal or dusty farm environments).

- Checking and draining condensate from air dryers and filters.

- Annual inspection and potential changeout of the sieve material (which can last several years).

- Calibration of oxygen sensors and monitoring equipment.

A well-designed system operated within its specifications will provide years of reliable service. It is highly recommended to partner with a supplier that offers clear maintenance guidelines, easy access to spare parts, and technical support experienced with aquaculture-specific challenges, such as corrosion protection options.

Conclusion

The integration of on-site oxygen generation is more than an equipment upgrade; it represents a fundamental step towards precision aquaculture. It moves oxygen management from a reactive, limiting factor to a proactive, empowering tool. By guaranteeing the single most vital resource for aquatic life, farmers gain unprecedented control over their production environment, unlocking higher yields, superior stock health, and enhanced operational resilience.

For operations looking to intensify production, improve sustainability metrics, or simply eliminate the anxiety of oxygen-related crashes, investing in a reliable oxygen supply system is a strategic decision. It lays the foundation for growth and stability in an increasingly competitive and technical industry.

As a provider of industrial gas solutions, MINNUO understands the critical nature of dependable equipment in demanding environments like aquaculture. We are committed to offering robust, efficient oxygen generation systems designed to meet the specific challenges of modern fish farming, helping our clients build a more secure and productive future.

sales2:+86 17506119168

sales2:+86 17506119168