In the world of ice cream, a delicate and silky appearance is undoubtedly the first choice of consumers. With the advancement of technology, ice cream factories have found a new solution – liquid nitrogen machine. Liquid nitrogen machine not only makes the texture of the dough smoother, but also makes the flavor more layered, which helps the factory to produce better products, making it popular in the market. This article will explore how liquid nitrogen machine can bring value upgrades in cold production and provide production advantages for factories.

Liquid nitrogen machines rely on ultra-low temperature and rapid freezing technology to significantly improve the taste and flavor of ice cream, achieving a smooth taste that “melts in the mouth”. Liquid nitrogen machines not only quickly lock the taste of ice cream, but also avoid the formation of coarse ice crystals in traditional freezing, bringing a rich and high-density taste. In addition, liquid nitrogen freezing is energy-saving and environmentally friendly, saves large cold storage, improves production efficiency, and helps ice cream factories achieve product adjustments and quality consistency, becoming an important technology for the ice cream industry to improve quality and market competitiveness.

Working principle of liquid nitrogen machine: ultra-fast freezing brings silky taste

The temperature of liquid nitrogen is extremely low, usually maintained at -196°C, and has the characteristics of instant freezing. Liquid nitrogen machine uses this ultra-low temperature characteristic to play a “magical” freezing effect in ice cream production. Liquid nitrogen machine sprays liquid nitrogen to make ultra-low temperature liquid nitrogen quickly contact the ice cream raw materials, quickly shape it in just a few seconds, and form a delicate texture. This ultra-fast freezing process can quickly freeze the water in the ice cream into extremely small ice crystals, avoiding the roughness of large ice crystals formed during freezing, making the ice cream taste smoother and denser.

The uniqueness of liquid nitrogen freezing is that it is not only fast, but also “casts magic” on ice cream, so that every bite of ice cream reaches the best height. The temperature control and freezing speed adjustment of the liquid nitrogen machine allow the ice cream factory to provide “customized” freezing solutions for ice cream with different flavors and textures, and achieve precise control of taste and flavor.

The uniqueness of liquid nitrogen freezing is that it is not only fast, but also “casts magic” on ice cream, so that every bite of ice cream reaches the best height. The temperature control and freezing speed adjustment of the liquid nitrogen machine allow the ice cream factory to provide “customized” freezing solutions for ice cream with different flavors and textures, and achieve precise control of taste and flavor.

Four ways that liquid nitrogen machines improve ice cream

Extremely delicate feeling: make ice cream melt in your mouth

The texture and taste of ice cream are directly affected by the freezing speed. In the traditional freezing method, due to the freezing process, water molecules gather into enlarged ice crystals, resulting in a slightly rough taste of ice cream. The extremely fast freezing of the liquid nitrogen machine instantly freezes water molecules into tiny ice crystals, bringing an extremely delicate texture. Every bite is like a cloud melting on the tip of the tongue, bringing an unparalleled “melt in your mouth” experience, greatly enhancing the enjoyment of watching.

Flavor locking, distinctive sweet aftertaste

The ultra-low temperature freezing of the liquid nitrogen machine can not only lock the temperature, but also seal the natural active molecules in the ice cream. In the ultra-low temperature freezing of the liquid nitrogen machine, long-term low temperature can easily volatilize the active substances, while liquid nitrogen freezing ensures that the flavor components such as milk, pulp, and chocolate are not lost, so that every bite of ice cream has a rich and lasting flavor layer, which makes people have endless aftertaste.

High-density taste: rich taste experience

It is not easy to introduce air during liquid nitrogen freezing, which makes the density of the cream higher and the texture more solid and heavy. Unlike the traditional way of adding air to increase the fluffy feeling in freezing, liquid nitrogen freezing makes the texture of the cream more precise and rich. Every bite of ice cream is full of milky fragrance, bringing a rich taste, adding “realism”, and giving people countless taste enjoyment.

Flexible adjustment to meet the taste requirements of dishes

The liquid nitrogen machine not only has a fast freezing speed, but its freezing temperature and injection volume can also be adjusted according to demand. The freezing factory can provide different freezing effects for different products by controlling the amount and time of liquid nitrogen injection. For a light and melt-in-the-mouth texture, you can choose a shorter freezing time; for the photon taste, you can extend the freezing time. The flexible freezing of the liquid nitrogen machine enables the ice cream factory to provide more diversified products, meet different taste requirements, and enhance market power.

The core advantages of liquid nitrogen machines in ice cream factories

The liquid nitrogen machine not only makes the ice cream taste better, but also brings locking advantages in production efficiency and cost, providing ice cream factories with greater operating space.

Extremely fast freezing, significantly improved production efficiency

The liquid nitrogen freezing process only takes a few seconds to quickly shape the ice cream raw materials, greatly improving production efficiency. Compared with traditional freezing, liquid nitrogen freezing is several times faster, allowing the factory to complete mass production in a short time. The efficient freezing of the liquid nitrogen machine saves a lot of waiting time for the production line, and a total of 10 cycles of freezing stages have been experienced, which greatly improves the factory’s production capacity.

Energy saving and consumption reduction, meeting environmental protection requirements

The liquid nitrogen machine does not need to rely on large cold storage and freezing tunnels, reducing the investment in site and equipment costs, and greatly reducing demand. The high efficiency of the liquid nitrogen machine can enable the equipment to run traditional freezing equipment for a long time, achieving energy saving and consumption reduction. Liquid nitrogen freezing meets the requirements of modern food production for green environmental protection, helping ice cream factories to move towards sustainable development while improving product quality.

High consistency to ensure high quality of each batch

The extremely fast freezing of the liquid nitrogen machine can quickly freeze and shape the ingredients. This stability of the liquid nitrogen machine brings higher quality assurance to the factory, ensuring that the taste and texture of each batch of candy meet the same high standards, winning the trust of consumers.

Promote product innovation and enrich ice cream product lines

Liquid nitrogen freezing technology brings unlimited possibilities for ice cream factories to develop new products. In addition to classic ice cream, liquid nitrogen freezing produces a variety of frozen desserts such as fruit ice cream, fruit puree ice cream, smoothies, etc., providing consumers with a variety of frozen dessert choices.The application of liquid nitrogen machines not only enhances the factory’s innovation ability, but also enriches the product line and brings more market opportunities to the factory.

The flexibility of liquid nitrogen freezing also helps factories develop nutritionally customized products, such as low-sugar, low-fat, high-protein ice cream, to meet consumers’ health needs. This expansibility of liquid nitrogen freezing allows factories to improve their market competitiveness while meeting different consumer preferences.

The potential of liquid nitrogen machines for the future development of the ice cream industry

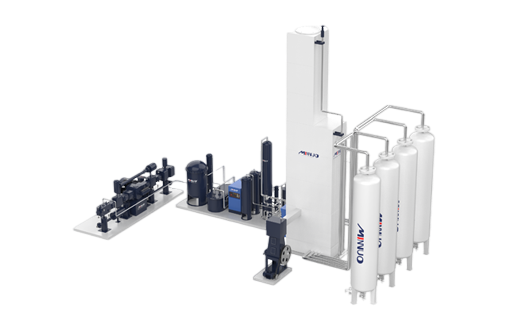

With fierce market competition, ice cream consumers’ demands for taste, quality and nutrition continue to increase. Liquid nitrogen freezing technology undoubtedly provides a new direction for the future development of the ice cream industry. With the future of ultra-low temperature, extreme freezing, energy saving and environmental protection, liquid nitrogen machines are expected to become standard equipment for ice cream factories, helping companies achieve breakthroughs in production efficiency and product quality. The liquid nitrogen machine produced by MINNUO is very popular among ice cream manufacturers. Customers have reported that the sales of ice cream have increased significantly after using the liquid nitrogen machine. Many people believe that this is due to the improved formula.

Liquid nitrogen freezing technology also has wide application potential in other frozen foods, such as quick-frozen high-efficiency juices, frozen drinks, etc. This freezing method is not only energy-saving, but also helps factories reduce their carbon footprint, which is in line with the trend of green production. With the development of health and environmental awareness, the improvement of liquid nitrogen freezing technology will gradually become the standard of the food freezing industry and promote food companies to achieve sustainable development goals.

Conclusion

The introduction of liquid nitrogen machines has brought revolutionary changes to the ice cream industry. In the future, liquid nitrogen machines will play a more efficient role in ice cream and the wider frozen food industry, helping factories to produce, save energy and protect the environment, and innovate and develop. With the popularization of liquid nitrogen freezing technology, the ice cream industry will enter a new era of higher quality to meet consumers’ demand for delicious food. MINNUO liquid nitrogen machine is like a “magician” in an ice cream factory, using technology to give ice cream an irresistible taste experience and enrich people’s taste world. If you also want to make a qualitative leap in the ice cream or other frozen foods you make, please consult our MINNUO official website. We will provide you with the best products and the most favorable prices.

sales2:+86 17506119168

sales2:+86 17506119168