Nitrogen generator is a kind of equipment widely used in many fields such as industry, medical treatment, food packaging, etc. It can provide high nitrogen and plays an important role in preventing oxidation and maintaining product quality. When users choose and use nitrogen generators, they often ask a core question: How long can the machine be used? By understanding the life of the nitrogen generator, users can make better purchasing decisions and extend the service life of the equipment. This article will delve into the standard life of the nitrogen generator, the statistics that affect the life, and provide some tips to extend the life of the equipment to help you get higher economic returns in daily operations.

Generally, the design life of a nitrogen generator is between 10 and 15 years. However, the actual life of the equipment still depends on the type of equipment and the application environment.

Standard life of a nitrogen generator

The following are the common nitrogen generator types and their standard service life:

Pressure swing adsorption nitrogen generator (PSA)

This type of nitrogen generator separates this oxygen and oxygen in the air through adsorbents. Under normal circumstances, the life of a PSA nitrogen generator is 10 to 15 years, but the wastewater of the adsorbent is 5 to 8 years and needs to be replaced regularly.

Membrane separation nitrogen generator

The membrane separation nitrogen generator uses a hollow fiber membrane to separate oxygen and oxygen in the air. The service life of the membrane element is usually 5 to 7 years. After regular replacement of the membrane element, the equipment as a whole can continue to be used for more than 10 years.

Chemical nitrogen generator

Since chemical reactions will generate by-products, the mortality rate of chemical nitrogen generators is generally 3 to 5 years.

The consumption of different types of nitrogen generators varies, but their consumption is affected by factors such as equipment quality, maintenance methods, and use environment. Next, we will analyze in detail the main factors affecting the consumption of nitrogen generators.

Key factors affecting the life of nitrogen generators

Equipment quality

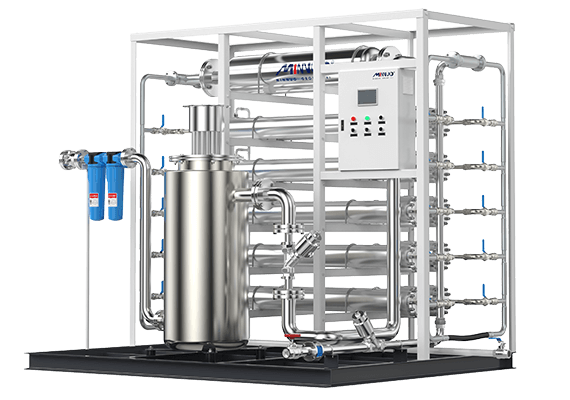

The quality of the equipment directly affects its service life. High-quality nitrogen generators are usually made of high-quality materials and processed through strict manufacturing processes. When selecting equipment, choosing a well-known brand such as MINNUO can ensure higher quality and longer service life. High-quality components and strict manufacturing processes make the equipment more stable in long-term operation.

Operation specifications

The operation mode of the equipment has a significant impact on wear. Irregular operations, such as intermittent overload use, incorrect start-up or shutdown procedures, will accelerate the wear of the equipment. Users should strictly follow the regulations in the equipment operation manual to ensure that the equipment operates in the best condition.

Operation environment

The operating environment of the nitrogen generator will directly affect its service life. If the equipment is operated in an environment with excessive temperature, excessive humidity or sedimentation baseline for a long time, the internal components may age rapidly. Placing the equipment in a dry, well-ventilated and clean environment can significantly extend its service life.

Maintenance Regular

maintenance is the key to extending the service life of the equipment. Users need to regularly replace wearing parts such as filter elements and adsorbents according to the use of the equipment to ensure normal operation. Failure to maintain the equipment in time may cause small faults to accumulate into big problems, and the equipment will be consumed every week.

Tips for Extending the Consumption of Nitrogen Generators

To make the manufacturing nitriding machine “live longer”, users can effectively extend the service life of the equipment through the following tips:

Develop a detailed maintenance plan

A detailed maintenance plan has been developed for the nitrogen generator to ensure that the equipment is cleaned and inspected within an appropriate period. It is recommended that users check the equipment monthly, especially the filters and air passages, to ensure that they are not blocked. Deeply clean and fully inspect the equipment every quarter, including checking whether key components are worn.

Replace consumables in time

Filter elements, adsorbents and membrane elements are key consumables for nitrogen generators, and users should replace these components regularly according to the operating status of the equipment. For example, when the equipment is restarted at night or the efficiency is reduced, it usually means that the consumables need to be replaced. Replacing these key components in time can ensure that the equipment remains efficient throughout its life cycle.

Monitoring operating parameters

Modern nitrogen generators often come with intelligent monitoring systems, allowing users to track the equipment’s status in real time. These systems help detect abnormalities in parameters like operating pressure, temperature, and air pressure. Users can then make timely adjustments, preventing potential issues and ensuring smooth operation.

Keep the equipment clean

Although the nitrogen generator doesn’t produce excessive loss or waste during operation, moisture and oil in the air gradually accumulate on internal components. Regular cleaning, especially of the vents and filters, can significantly reduce wear and extend the equipment’s lifespan.

Optimize the operating environment

The operating environment of the equipment is the key to its life. Users should try to place the equipment in a location with low temperature, low humidity and good air quality. If the equipment is partitioned or in an environment with high humidity, it is recommended to install air conditioning or dehumidification equipment to improve the environment and avoid the equipment from being scrapped prematurely due to environmental problems.

Nitrogen generator consumption and return on investment

When purchasing equipment, users should consider not only the price but also the service life and overall return on investment. High-quality equipment may have a higher initial cost, but lower maintenance expenses and longer usage can lead to a higher return on investment over time.

Advantages of long-term consumption equipment

high-quality nitrogen generators have low maintenance frequency and often short maintenance time, which reduces the risk of interruption in production. Although the investment increases, the long-term benefits it brings far exceed low-priced equipment.

Interruption of short-term consumption equipment

Although the investment in the equipment is low, its consumption is short and the failure rate is high. The cost of maintenance and replacement in long-term use will gradually increase. In addition, equipment interruption failure will lead to frequent production lines, which will cause great losses to the enterprise. Bringing large economic losses.

Frequently Asked Questions (FAQ)

How to judge whether the nitrogen generator needs to replace the filter element?

When the nitrogen gas of the equipment needs to be short-circuited or the flow rate is reduced, it may mean that the filter element is blocked and needs to be replaced.

How should the maintenance frequency of the nitrogen generator be arranged?

It is recommended to conduct an equipment inspection once a month, deep cleaning and maintenance once a quarter, and a comprehensive overhaul once a year. MINNUO will provide you with specific maintenance plans for individual situations.

Does the brand have an impact on the service life of the nitrogen generator?

Yes, the well-known brand MINNUO usually uses higher quality materials and manufacturing processes, so the equipment has a longer service life and better stability.

Conclusion

This article aims to give you a clear understanding of the nitrogen generator’s lifespan and how to extend it. By using proper operation and regular maintenance, you can improve the equipment’s efficiency and prolong its service life. If you encounter any problems, you can consult the MINNUO official website. We are always here to answer your questions.

sales2:+86 17506119168

sales2:+86 17506119168