In metalworking industries such as laser cutting, plasma cutting, and precision welding, oxygen is more than just a fuel—it is a critical enabler of clean cuts, fast throughput, and product consistency. The purity and pressure of oxygen directly impact cut edge quality, dross formation, and even the life expectancy of equipment. For fabrication plants pursuing higher efficiency and tighter tolerances, oxygen quality is not optional—it is essential.

Unfortunately, many workshops still rely on bottled oxygen or inconsistent external supplies. This often leads to problems such as pressure fluctuations, supply delays, or variable purity—all of which result in incomplete cuts, excess rework, and downtime. When oxygen fails, productivity suffers. These issues can cost thousands of dollars annually in lost output and maintenance.

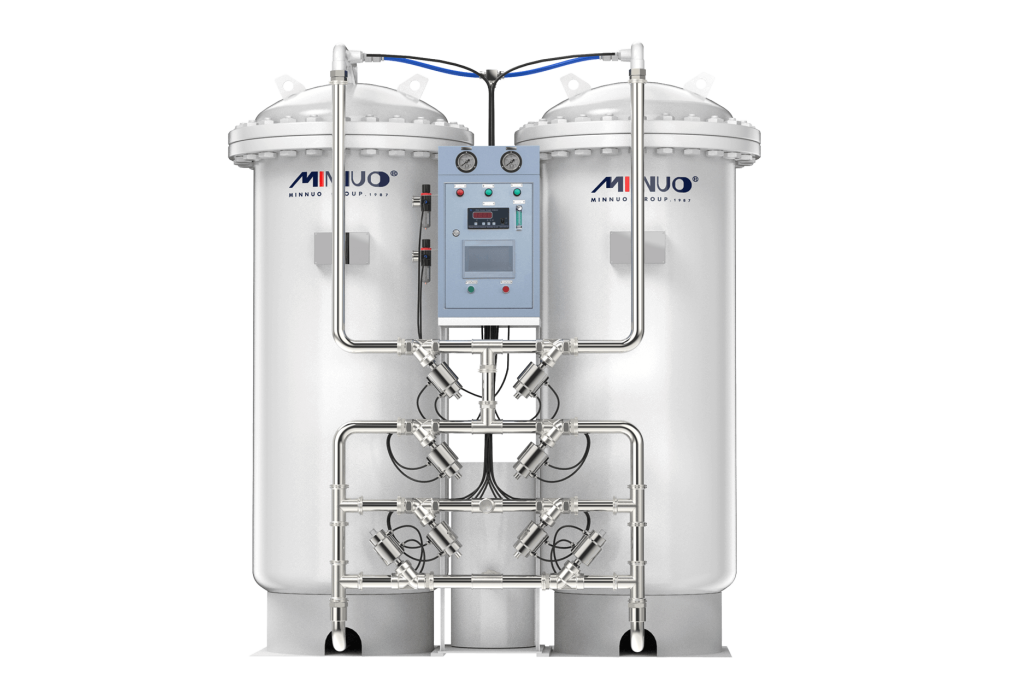

To meet the increasing demand for stable and efficient production, fabrication facilities around the world are turning to on-site oxygen generation. With consistent purity (93±3%), no delivery delays, and long-term cost savings, PSA oxygen generators—like those offered by MINNUO—are rapidly becoming the standard in modern industrial gas strategy. Read on to explore how upgrading your oxygen supply can dramatically enhance your shop’s cutting performance and profitability.

1. The Role of Oxygen in Cutting and Welding Processes

In cutting and welding applications, oxygen is not just a support gas—it is an active process enhancer. Its role varies by technique but always affects precision, efficiency, and operational cost.

Laser Cutting

Oxygen is used as an assist gas to promote an exothermic reaction with the material, accelerating the cut and helping eject molten metal. This is particularly effective for carbon steel, where oxygen contributes both thermal energy and oxidation.

Real-world benefit:

A consistent oxygen flow (≥93%) can reduce cut time by up to 20% while improving edge finish—less secondary processing required.

Common issue solved:

Fluctuations in gas pressure from cylinders often cause inconsistent kerf widths and dross buildup. On-site generation ensures stability.

Plasma Cutting

While oxygen isn’t the plasma-forming gas (typically air or nitrogen), it can be used in specialized systems to improve edge precision on thinner mild steels. Its high reactivity makes it ideal for clean, low-resistance cuts.

Use tip:

When cutting <6mm carbon steel, using oxygen instead of air improves arc stability and reduces bevel angle deviation.

Oxy-Fuel Cutting

Here, oxygen is the cutting gas, reacting with preheated metal to sustain combustion and perform the actual cut. The required purity is higher—usually ≥99.5% for clean, fast ignition and minimal slag.

Why purity matters:

Low-purity oxygen (e.g., <90%) can cause delayed ignition and rough cut surfaces, increasing the risk of thermal distortion.

With on-site generation:

A PSA system with a booster can deliver up to 95%+ purity at 30 bar, reducing reliance on costly cryogenic tanks.

Welding (TIG/MIG)

In TIG and MIG processes, oxygen is blended in minute quantities (usually <5%) with argon or CO₂ to control bead shape, arc temperature, and penetration.

Application impact:

For stainless steel, oxygen addition can improve arc focus and reduce porosity—but too much will oxidize the weld pool.

On-site value:

With modular gas blending systems connected to PSA generators, operators can adjust ratios in real-time instead of ordering pre-mixed cylinders.

Technical Note

Purity vs. Performance:

Even seemingly small changes in oxygen purity (93% vs. 99.5%) can affect:

| Parameter | ≥93% Purity | ≥99.5% Purity |

| Ignition Point | Slightly delayed | Instantaneous |

| Kerf Width | Slightly wider | Narrow, clean |

| Edge Smoothness | Moderate burrs possible | Minimal post-processing |

| Gas Cost | Lower (PSA) | Higher (cylinders/liquid) |

Decision tip: For cutting ≥10mm carbon steel in mass production, ≥93% is often sufficient. For aerospace-grade stainless welding, ≥99.5% may be required.

2. Challenges with Traditional Oxygen Supply

Despite being widely used, traditional oxygen supply methods—like gas cylinders and cryogenic liquid tanks—pose several operational risks and inefficiencies, especially in modern industrial environments where speed and stability are crucial.

2.1 Frequent Interruptions Due to Delivery Delays

Reliance on external oxygen deliveries exposes operations to transport disruptions, supplier delays, or local shortages.

Example scenario:

A metal fabrication plant loses 6 hours of production every time a scheduled cylinder delivery is delayed—even more if it falls on a weekend or public holiday.

2.2 High Cost for High-Consumption Users

The more oxygen you consume, the more expensive traditional sourcing becomes. Pricing includes cylinder rental, delivery fees, handling, and tank loss surcharges.

Hidden cost breakdown:

Daily rental per cylinder

Return loss due to incomplete usage

Price inflation due to market instability

Over a year, these costs can far exceed the investment in an on-site PSA oxygen system.

2.3 Pressure Instability and Purity Fluctuation

As cylinders empty, output pressure drops, affecting cutting quality. Impurities can also mix in, particularly during valve transitions or tank changes.

Impact on production:

Inconsistent oxygen flow leads to uneven weld beads and jagged cuts—requiring rework or edge grinding.

2.4 Safety and Regulatory Burdens

Storing high-pressure oxygen cylinders or cryogenic tanks requires strict compliance with fire codes, ventilation, zoning, and training regulations.

Risk exposure:

Explosion/fire hazard in enclosed spaces

Regulatory fines for improper storage

Periodic audits and paperwork management

2.5 Downtime from Cylinder Changeover & Logistics

Each cylinder replacement requires stopping the machine, bleeding the line, reconnecting fittings, and leak testing. Multiply this by multiple lines and you lose serious time.

A facility replacing 10 cylinders per day can lose up to 2 hours of productive time daily—that’s nearly 500 hours per year.

3. Advantages of On-Site Oxygen Generators in Cutting & Welding

3.1 Stable Oxygen Purity and Pressure

No fluctuations → More consistent cut/weld quality

Real-time monitoring systems available in modern PSA oxygen generators

3.2 Lower Operating Cost

Eliminates recurring delivery fees and rental charges

Payback period often <18 months for mid- to high-volume users

3.3 Higher Cutting Speed & Quality

With consistent ≥93% purity, users report up to 20% improvement in cutting efficiency compared to cylinders

Improved ignition, smoother cut surfaces, reduced slag

3.4 Reduced Downtime

No waiting for refills or deliveries

Continuous production in 24/7 operations

3.5 Enhanced Safety and Sustainability

No high-pressure tanks → lower explosion/fire risks

Lower carbon footprint with reduced transportation and emissions

4.Case Study: Oxygen Generator in a Laser Cutting Facility

This real-world example demonstrates how on-site oxygen generation can drive operational savings and improve cutting performance in a high-throughput industrial setting.

Client Overview

Company: Metal part manufacturer, Turkey

Industry: Sheet metal processing for automotive and machinery sectors

Production Mode: 3-shift, 24/7 operation with CNC laser cutting lines

Use Case Scenario

Before:

Weekly consumption: 40 high-pressure oxygen cylinders

Frequent tank swaps and delayed deliveries

Inconsistent cut quality during high-volume jobs

After:

Installed 60 Nm³/h PSA oxygen system

Full setup: PSA Generator + Air Compressor + Air Dryer + Oxygen Buffer Tank

Switched to pipeline-based continuous oxygen supply

Measurable Results

| KPI | Before (Cylinders) | After (On-Site PSA) | Improvement |

| Oxygen cost/month | $3,200 | $1,760 | ↓ 45% |

| Average cutting time/job | 45 mins | 38 mins | ↓ 15% |

| Laser head maintenance | Every 200 hrs | Every 350 hrs | Extended lifespan |

| Cylinder handling time | ~1.5 hrs/day | 0 hrs | Fully eliminated |

Client Testimonial

“The stable pressure and gas quality significantly reduced rework and improved our cut consistency.

We used to halt production just to change tanks—now the line keeps running.”

Analysis: Why the Results Matter

Cost savings are not just in gas—downtime, labor, and tool wear also improved

Cutting consistency enabled tighter tolerances, reducing customer rejections

On-site oxygen removed dependency on logistics, a major benefit during fuel price hikes and supply chain instability

Bonus Insight: Scalability

This client started with a 60 Nm³/h unit, but the system was modular—allowing future expansion to 90 Nm³/h by adding a second generator without redesigning the whole system.

Takeaway: For medium to large-scale laser cutting operations, on-site PSA oxygen is not just cheaper—it’s operationally smarter.

5.Recommended Oxygen Generator Configuration for Fabricators

To ensure stable oxygen delivery, high cutting efficiency, and long-term reliability, a properly designed oxygen generation system should include the following components:

5.1 PSA Oxygen Generator

Purpose: Core system for continuous on-site oxygen production

Typical Purity: 93% ±2%, ideal for most laser, CNC, and oxy-fuel cutting tasks

✅ Why it’s suitable:

Supports 24/7 operation

Lower running cost than cylinders

No need for liquid oxygen storage permits

Note: For medical-grade or high-purity welding (e.g. titanium), additional purification steps may be required.

5.2 Optional: Oxygen Booster

Purpose: Increases output pressure when your process requires ≥20 bar

✅ When to use it:

CNC machines with high-pressure injectors

Oxy-fuel cutting requiring intense flame velocity

Multi-line distribution across large workshop areas

Common output pressures: 20–30 bar (adjustable)

5.3 Pre-Treatment Units

Components:

Air Dryer: Removes moisture from compressed air

Filters: Eliminate dust, oil vapors, and micro-particles before air enters the PSA system

✅ Impact on performance:

Clean, dry air is critical for protecting the molecular sieve inside the PSA—extending service life by up to 3 years.

5.4 Oxygen Buffer Tank

Function: Stores oxygen and smooths out demand spikes during intensive cutting periods

✅ Why it matters:

Prevents oxygen pressure drops during laser bursts

Reduces on/off cycling of the generator, extending mechanical life

Acts as a safety buffer in case of temporary power loss

Recommended size: 500–1000 liters per 50Nm³/h of output

5.5 Monitoring System (Optional but Highly Recommended)

Features:

Touch-screen control panel for local management

Real-time oxygen purity and flow rate monitoring

Remote diagnostics via cloud or LAN

✅ Why it adds value:

Helps detect filter saturation or flow issues early

Enables preventive maintenance scheduling

Useful for multi-factory environments or 24/7 remote supervision

FAQ

Can PSA oxygen reach 99% purity?

Answer:

Standard PSA (Pressure Swing Adsorption) systems typically produce oxygen with 90%–95% purity. While technically possible to reach up to 96%, achieving ≥99% purity consistently requires additional purification technologies (such as VPSA, catalytic deoxidizers, or cryogenic methods).

✅ For most cutting and welding processes, 93% purity is more than sufficient. Only specialty applications (e.g. aerospace TIG welding) require ultra-high-purity oxygen.

How do I calculate the flow rate needed for my plasma cutter?

Answer:

Flow rate depends on the cutting amperage, material thickness, and nozzle size. A general rule of thumb is:

arduino

CopyEdit

Required flow (L/min) = [Amperage] × 0.7 ~ 1.2

Example:

A 100A plasma cutter may require 70–120 L/min of oxygen, depending on usage mode.

For multi-machine environments, always add a 20–30% buffer to cover simultaneous operation and peak demand.

Is on-site oxygen generation safe for indoor use?

Answer:

Yes—PSA oxygen systems are designed for safe indoor installation. Unlike high-pressure cylinders or liquid oxygen tanks, PSA systems operate at moderate pressures and do not store large oxygen volumes.

Built-in safety features include:

Overpressure protection

Oxygen leakage monitoring

Temperature sensors and emergency shutdown

Many units are also skid-mounted with full enclosures for added safety and easy maintenance.

Can the system support multiple machines simultaneously?

Answer:

Absolutely. PSA oxygen systems can be scaled modularly and connected to a central distribution pipeline, allowing them to supply multiple laser cutters, welding stations, or CNC machines at once.

To ensure stable performance:

Use a properly sized buffer tank (based on peak demand)

Include flow regulators or split valves per machine

Monitor purity and pressure with an integrated control panel

Tip: If you’re expanding operations, choose a generator with at least 15–20% headroom for future growth.

Conclusion

Switching from bottled oxygen to an on-site oxygen generator is more than just a cost-saving move—it’s a strategic upgrade in cutting and welding productivity. With uninterrupted gas supply, reduced downtime, and consistent purity levels, fabrication shops can expect smoother operations and improved metalwork quality.

Whether you’re a small workshop or a large industrial facility, on-site oxygen generation scales flexibly with your needs. It’s especially ideal for businesses seeking independence from fluctuating cylinder prices and unpredictable delivery schedules.

At MINNUO, we offer complete PSA oxygen generation systems tailored to metal cutting and welding applications. Before you invest, we recommend using our ROI calculator and speaking with a MINNUO engineer to determine the optimal system configuration for your site.

Ready to cut costs and boost efficiency? Get your tailored solution now → https://minnuoagro.com

sales2:+86 17506119168

sales2:+86 17506119168