Medical oxygen is a vital resource in healthcare, playing an essential role in life-saving treatments. From hospitals to emergency services, reliable and high-quality oxygen is required to support patients with various conditions, such as respiratory failure, during surgeries, or while undergoing intensive care. This article explores the significance of high-purity medical oxygen and the growing need for on-demand, dependable oxygen supply systems.

In medical settings, oxygen is not just a necessity but often a life-saving intervention. The role of medical-grade oxygen, typically delivered at purity levels above 93%, is crucial for ensuring that patients receive the best care, particularly in critical care environments like intensive care units (ICUs) and operating theaters. Whether assisting with respiratory support, anesthetics, or other therapeutic applications, oxygen is integral to maintaining patient health and recovery.

With increasing demands and fluctuating supply logistics, ensuring that healthcare facilities have a continuous and reliable source of high-purity oxygen has become more important than ever. In the following sections, we will explore the solutions that PSA (Pressure Swing Adsorption) oxygen generators offer, highlighting how they meet the growing needs for high-purity oxygen in medical facilities and improve operational efficiency in healthcare settings.

1. What is a High Purity PSA Oxygen Generator?

Explanation of PSA Technology

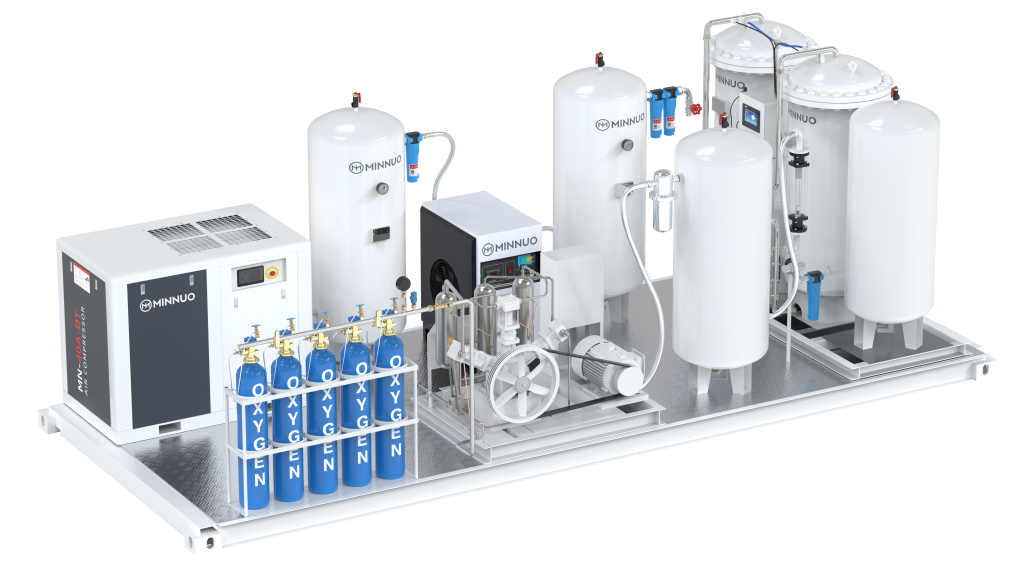

A PSA (Pressure Swing Adsorption) oxygen generator is an efficient and reliable method used to produce high-purity oxygen from ambient air. It works by utilizing adsorbent materials such as zeolite to separate nitrogen from oxygen. This process is crucial for meeting the high purity requirements in medical applications, typically requiring oxygen purity levels of 93% or higher.

How PSA Works

PSA technology starts with air filtration to remove contaminants like dust, moisture, and carbon dioxide. The air is then compressed and passed through adsorbent materials that selectively trap nitrogen, leaving behind oxygen. The purified oxygen is collected and stored, while the nitrogen is vented out. The system cycles through this process, providing a continuous supply of oxygen.

Why Purity Matters in Healthcare

For medical applications, oxygen purity is vital. Oxygen with purity levels between 93% and 99% is typically required for patient safety and effective treatment. The higher the purity, the better it supports critical care, such as in hospitals, surgery rooms, and other healthcare facilities where reliable, contaminant-free oxygen is a necessity.

Efficiency & Energy Considerations

A high purity PSA oxygen generator is designed for efficiency. It consumes less energy compared to other oxygen production methods, such as electrolysis or cryogenic oxygen production, while delivering high output. The system is highly scalable, allowing it to meet the needs of both small clinics and large hospitals without incurring excessive operating costs.

2. Why Choose a PSA Oxygen Generator for Medical Applications?

Reliability: Continuous, On-Demand Oxygen Supply

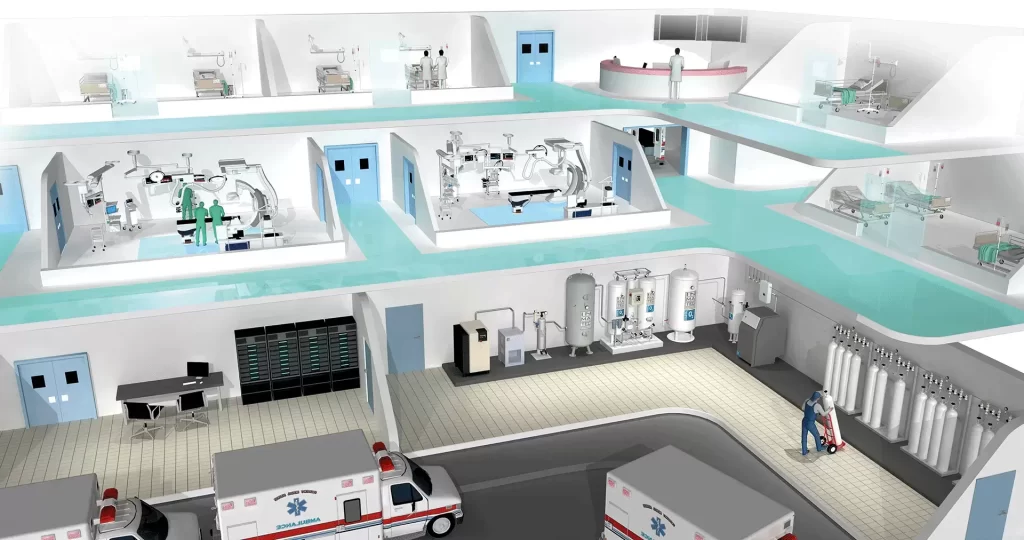

One of the primary reasons to choose a PSA oxygen generator for medical applications is its reliability in providing a continuous, on-demand supply of oxygen. In critical healthcare settings, such as emergency rooms, intensive care units (ICU), and surgical theaters, a steady and uninterrupted oxygen supply is paramount. PSA systems are designed to deliver oxygen 24/7, eliminating the risk of supply disruptions caused by delivery delays or storage issues associated with traditional systems.

By using PSA oxygen generators, hospitals and medical facilities can ensure they have a stable and consistent source of oxygen, which is crucial for maintaining patient care during both routine and emergency procedures.

Cost-Effectiveness: Reducing Dependency on External Supplies

For many healthcare providers, the ongoing cost of purchasing and transporting liquid oxygen (LOX) or relying on cryogenic oxygen systems is a significant financial burden. PSA oxygen generators offer a cost-effective alternative by producing oxygen on-site, eliminating the need for recurring deliveries.

The generator’s one-time installation cost is offset by long-term savings in transportation fees, storage costs, and the price volatility often seen with liquid oxygen deliveries. As the medical facility’s demand grows, the PSA system can scale, further reducing operating expenses and ensuring the oxygen supply remains affordable and efficient.

Quick Delivery: Fast On-Site Oxygen Production

In medical emergencies, timely access to oxygen is vital. PSA oxygen generators can rapidly produce oxygen on-site, reducing the waiting time for external oxygen deliveries. This quick production is especially critical in facilities that experience fluctuations in oxygen demand or need immediate replenishment during medical emergencies, surgical procedures, or intensive care situations.

Having an on-site PSA system ensures that hospitals and clinics are never at the mercy of delivery delays, which could be detrimental to patient health. Immediate availability of oxygen makes it an essential tool for healthcare institutions that prioritize patient safety and care.

Advantages Over Traditional Systems

PSA oxygen generators offer distinct advantages over traditional oxygen supply methods, such as liquid oxygen tanks, cryogenic systems, and electrolysis-based methods.

Liquid Oxygen Tanks: While liquid oxygen is still commonly used, it requires storage tanks and regular deliveries, which incur ongoing costs and logistical complications. PSA systems, on the other hand, produce oxygen on-demand and avoid the logistical challenges associated with transporting liquid oxygen.

Cryogenic Systems: Cryogenic oxygen systems are effective, but they often involve high capital investment, complex operation, and expensive maintenance. PSA systems are simpler to maintain and can be operated at a lower cost.

Electrolysis-Based Methods: While electrolysis is another method for generating oxygen, it generally requires substantial energy input, making it more expensive and less energy-efficient compared to PSA systems.

PSA systems stand out for their low energy consumption and simplicity while delivering high-purity oxygen suitable for medical use.

Flexibility to Meet Customer Needs

PSA oxygen generators are adaptable to meet the diverse needs of medical facilities. Whether a hospital has a small oxygen demand or requires a continuous, large-scale supply, PSA systems can be customized to match the facility’s specific requirements.

For example:

Hospitals with High, Constant Demand: Hospitals with intensive care units or emergency departments, where oxygen use is high and continuous, can benefit from PSA generators’ reliability and scalability.

Remote Healthcare Facilities: In regions with limited access to regular oxygen supply routes, PSA systems provide a crucial lifeline by offering a local and constant source of oxygen, especially in rural or isolated areas.

3. Benefits of High Purity Fast Delivery PSA Oxygen Generators

Key Points:

Continuous Supply: Ensuring No Interruptions in Critical Oxygen Supply

A primary advantage of high purity PSA oxygen generators is their ability to offer an uninterrupted supply of medical-grade oxygen. Unlike traditional systems that depend on external deliveries, which can be subject to delays or disruptions, PSA generators ensure that oxygen is available whenever it’s needed. This is critical in settings such as emergency rooms, intensive care units (ICUs), and surgical theaters, where oxygen is a life-saving resource. By installing a PSA oxygen generator, hospitals eliminate the risk of running out of oxygen due to supply chain issues or transportation delays.

Flexibility: Systems Can Scale to Meet Demand, from Small Clinics to Large Hospitals

PSA oxygen generators provide exceptional scalability, making them suitable for a wide range of medical applications. For smaller clinics, a compact PSA generator can provide just the right amount of oxygen, while larger hospitals with high oxygen demands can benefit from more powerful systems capable of handling large volumes. The ability to scale allows healthcare providers to future-proof their oxygen supply, adapting to increased demand as the facility grows. Whether it’s a small, rural clinic or a large metropolitan hospital, PSA systems can be tailored to fit specific needs, ensuring efficiency and cost-effectiveness.

Quick Start-Up: Providing Oxygen Rapidly Upon Demand, Essential for Critical Care and Emergencies

One of the most valuable features of PSA oxygen generators is their ability to provide oxygen quickly, ensuring there is no delay in critical care or emergencies. In urgent situations, such as resuscitation or when a patient’s oxygen levels suddenly drop, PSA systems can produce oxygen immediately, without the wait typically associated with external deliveries. This fast delivery is crucial in hospitals, where every second counts, and is particularly valuable in emergency departments and ICUs.

Minimal Storage Requirement: No Need for Bulky, Hazardous Liquid Oxygen Storage Tanks

Another significant benefit of PSA systems is that they eliminate the need for storing bulky liquid oxygen tanks. Traditional oxygen supply methods rely on large storage tanks that need to be refilled regularly, creating a need for vast storage space and complicating logistics. PSA oxygen generators, however, produce oxygen on-site, requiring only a small storage unit for the produced gas. This not only saves space but also reduces the risks associated with handling and storing liquid oxygen, which can be hazardous due to its cryogenic nature. The compact and safe design of PSA generators makes them ideal for urban hospitals where space is often at a premium.

4. How to Choose the Right High Purity PSA Oxygen Generator for Your Medical Facility

Key Considerations:

Capacity: Matching the Oxygen Generator’s Output to the Facility’s Specific Demand

When selecting a PSA oxygen generator for your medical facility, the first consideration should be the capacity needed to meet your facility’s oxygen demand. This varies based on the size of your hospital, the number of patients, and the specific departments that require oxygen (e.g., ICUs, emergency rooms, surgical theaters). Too large a system can lead to wasted resources, while too small a system may result in oxygen shortages, affecting critical operations. It’s essential to accurately assess your oxygen needs based on peak demand and daily requirements to ensure the selected generator can supply the required amount without excess energy consumption or operational costs.

Purity: Ensuring Oxygen Is Produced at the Required 93%+ Purity, Critical for Healthcare

High purity oxygen (typically 93% or higher) is essential in medical applications as it supports healthy respiration and oxygenation for patients in critical care, especially those with respiratory conditions or undergoing surgery. The chosen PSA system should consistently meet these purity requirements to ensure patient safety and optimal care. Low purity oxygen can cause complications in medical treatments, making it critical to verify the system’s ability to maintain the necessary purity level, especially when dealing with specialized medical procedures such as anesthesia or life-support systems.

Redundancy: Backup Systems for High-Reliability Operations in Emergency Scenarios

In critical healthcare settings, downtime is not an option. Therefore, having a backup or redundancy system is crucial to ensure continuous oxygen supply, especially during emergencies or periods of high demand. Redundant systems or backup oxygen supply features (such as additional PSA units or storage tanks) can prevent costly disruptions in medical services. Backup systems should be integrated into the hospital’s infrastructure to provide automatic switching in case of a failure in the primary system, ensuring there is always an uninterrupted oxygen supply for patients.

Energy Efficiency: Minimizing Energy Consumption for Cost-Effective Operation

Hospitals are high-demand environments with continuous operational hours. As a result, energy consumption can quickly become one of the largest operational costs for PSA oxygen generators. Choosing an energy-efficient system is essential for reducing long-term operational costs. Look for systems that incorporate energy-saving technologies such as automated start/stop features, variable frequency drives (VFDs), and optimization controls that adjust oxygen production based on demand. Systems designed with energy efficiency in mind will lower electricity costs, which can be significant in large hospitals or multi-site medical facilities.

Customization: Tailored Solutions Based on Hospital Size, Patient Care Needs, and Facility Location

Each medical facility has unique requirements based on its patient care needs, the size of the operation, and its geographical location. For instance, a small rural clinic may need a compact, portable PSA system, while a large metropolitan hospital may require a larger, scalable system capable of supplying oxygen across multiple departments. Customization options also include specific features like adjustable oxygen flow rates, real-time monitoring, and integration with existing hospital infrastructure. Tailoring the system to your exact needs ensures the most efficient and cost-effective solution while accommodating future growth.

5. Cost Analysis: Is a High Purity PSA Oxygen Generator a Worthwhile Investment for Medical Facilities?

Key Points:

Initial Cost vs. Long-Term Savings:

When considering a high purity PSA oxygen generator, the initial investment can be substantial, often ranging from $50,000 to $300,000 depending on the size and capacity. However, this upfront cost should be viewed as a long-term investment, especially when compared to recurring costs associated with traditional oxygen supply methods, such as liquid oxygen deliveries. Liquid oxygen, while initially convenient, incurs ongoing transportation costs, storage fees, and the risk of price fluctuations.

For example, hospitals that rely on liquid oxygen often face issues like delayed deliveries, rising transportation costs, and supply interruptions. A PSA oxygen generator, on the other hand, allows for an on-demand oxygen supply, reducing or eliminating the need for external suppliers. This shift to an in-house oxygen system helps minimize unforeseen costs, improving the facility’s financial predictability and stability.

Operational Costs:

The operational costs of a PSA oxygen generator are relatively low when compared to the ongoing costs of using liquid oxygen or other external methods. Major operational costs include electricity to run compressors, air purification systems, and regular maintenance. PSA systems, however, are designed to be energy-efficient, ensuring that hospitals can save significantly on electricity costs over time. Maintenance typically involves periodic checks and replacements of filters and other components, which are much less frequent and less costly than the service fees associated with liquid oxygen tank deliveries.

Moreover, the modular nature of many PSA systems means that hospitals can scale the system based on their needs, avoiding the costs of oversized systems and ensuring they only pay for the capacity they require.

Payback Period:

The payback period for a PSA oxygen generator is generally short, typically between 2-4 years depending on the size of the facility and the frequency of oxygen usage. For larger hospitals or those with high oxygen consumption, the payback period may be on the shorter end of this range. In addition to savings on delivery costs, the operational savings from energy-efficient technology and low maintenance further accelerate the return on investment. Once the payback period is reached, hospitals can continue to benefit from a steady, low-cost supply of oxygen, with significantly reduced ongoing costs.

FAQ

1. Can a PSA oxygen generator be used in remote areas with limited access to oxygen deliveries?

Answer: Yes, PSA oxygen generators are particularly beneficial for healthcare facilities in remote areas where access to liquid oxygen deliveries is limited or unreliable. These systems allow facilities to produce oxygen on-site, ensuring a constant and uninterrupted supply without the need for external suppliers.

2. What is the expected lifespan of a PSA oxygen generator?

Answer: PSA oxygen generators are built to last, with an expected lifespan of 15-20 years or more with proper maintenance. Regular servicing and care can extend the life of the system and ensure it remains operational without significant downtime.

3. Can PSA oxygen generators be customized for specific medical needs?

Answer: Yes, PSA oxygen generators can be customized based on the specific oxygen output requirements of the medical facility. Whether it’s for intensive care units, emergency departments, or smaller clinics, systems can be tailored to provide the required oxygen purity and flow rate to meet the needs of the facility.

4. How does the PSA oxygen generator improve patient outcomes?

Answer: By ensuring a continuous and reliable supply of high-purity oxygen, PSA generators help maintain optimal oxygen levels for patients, especially those in critical care. This reduces the risk of oxygen shortages, improves patient recovery times, and supports better long-term health outcomes, particularly in emergency situations or intensive care units.

Conclusion

PSA oxygen generators provide hospitals and medical facilities with a reliable, cost-effective, and energy-efficient solution to meet their oxygen supply needs. By ensuring continuous, on-demand delivery of medical-grade oxygen, these systems improve operational reliability, reduce dependency on third-party suppliers, and offer substantial long-term cost savings.

For healthcare providers, investing in PSA systems means enhanced patient care, improved oxygen delivery, and increased system uptime. With reduced reliance on external oxygen sources, facilities can ensure that oxygen is always available when needed, leading to better patient outcomes and more efficient hospital operations.

At MINNUO, we understand the unique requirements of medical institutions, which is why we offer tailored PSA oxygen generator solutions that can be customized to meet your facility’s specific needs. We also provide comprehensive after-sales service, including setup, maintenance, and optimization support, to ensure that your system remains reliable and efficient over its lifespan.

Contact MINNUO today to discover how our PSA oxygen generators can enhance your healthcare operations, reduce operational costs, and support optimal patient care.

sales2:+86 17506119168

sales2:+86 17506119168