In medical, industrial, environmental protection and other key fields, oxygen compressor is not only a kind of conveying equipment, but also an important core to ensure the efficient and safe supply of oxygen. Whether it is to maintain stable oxygen supply in hospital ICU, or to provide high-pressure oxygen support in ozone reaction and glass combustion furnace, its performance stability and selection adaptability are directly related to the continuity and safety of the whole system operation.

However, many users have a misunderstanding in the implementation of the project: they mistakenly use ordinary air compressors instead of oxygen compressors, ignoring the risk of explosion of oxygen as a combustion gas under high pressure conditions. Oxygen compressor needs to use special oil-free compression structure, oxygen-resistant materials and explosion-proof electronic control system, and cannot be replaced arbitrarily. Different working conditions on the oxygen pressure, flow, lubrication and control methods also put forward completely different technical requirements.

For this reason, this article will focus on “application scenarios × technical parameters × material safety × control intelligence” four major dimensions, in-depth analysis of oxygen compressor key selection logic, to help readers clear up common misconceptions, combined with practical cases and configuration recommendations, scientific judgment of the appropriate model. If you are in the process of hospital expansion, gas system upgrade, or industrial oxygen program design, this article will provide you with a one-stop reference and implementation path for selection.

1. Analysis of common application scenarios

In practical applications, oxygen compressors have been widely used in the following three typical scenarios due to their high efficiency, safety and adaptability. Each type of scenario has significant differences in oxygen purity, pressure, output mode and system configuration, which need to be precisely matched.

1.1 Medical field: clean, stable and redundancy guarantee is the most critical

Application examples: hospital central oxygen supply, ICU oxygen warehouse, flow bottled oxygen filling station

Core requirements:

Oxygen purity should be maintained at 93%±3% (in line with YY/T 0298)

Oil-free compressor configuration, preventing oil from polluting the respiratory system

Low noise (<65dB) to adapt to wards and first aid environments

Supports access to UPS or back-up gas source to ensure 24h uninterrupted oxygen supply.

Recommended equipment configuration: two-stage oil-free compressor + storage tank + PLC linkage system + online purity monitor

1.2 Industrial field: high pressure – strong continuity – system matching

Application examples: oxygen-enriched combustion in glass melting furnaces, metal cutting, oxygen supply for ozone generators

Core requirements:

The supply pressure usually needs to be 10~200 bar to meet the high-pressure process

Long-term operation stability requirements High stability requirements for long-cycle operation, low tolerance for fluctuations

Air source purity is inferior to medical, but dust and water removal systems are still required

Recommended equipment configuration: oil-lubricated piston/screw oxygen compressor + aftercooler + high oxygen tank + explosion-proof electronic control system

1.3 Food and environmental protection: on-demand regulation + high adaptability + integrable control

Examples of applications: Oxygen injection into fermentation tanks, disinfection of drinking water, wastewater aeration

Core requirements:

Oxygen flow needs to be accurately controlled, often by automatic regulating valve systems, often by automatic regulating valve systems.

The pressure requirement is not high (0.3~1.0MPa), but it is more sensitive to energy-saving control

Remote data acquisition capability is needed to support SCADA or PLC interfaces

Technical suggestions: choose medium pressure oxygen compressor with frequency controller, combined with the oxygen flow meter and alarm system to realize the automatic closed-loop adjustment

2. Analysis of Key Technical Parameters

In the process of selecting oxygen compressor system, correctly identify and match the core parameters. In the selection process of oxygen compressor system, correctly identifying and matching the core parameters is a prerequisite to ensure the stable operation of the system. This section will focus on “pressure level, flow unit, material selection, cooling method” and other technical dimensions to help users make scientific judgments.

2.1 Oxygen Pressure Levels

Common output pressure range: 140 ~ 6000 psi (10~400 bar)

Medical oxygen supply system: commonly used low-pressure section (0.3~1.0 MPa)

Industrial applications such as laser cutting, glass combustion, ozone generation, etc.: commonly used medium and high-pressure section (10~200 bar)

Oxygen cylinder filling station, etc.: demand for ultra-high-pressure output of up to 300~400 bar

Suggestion: Depending on the pressure level of the end-use equipment, make sure that the compressor output has a pressure stabilizer module + safety valve to prevent the risk of overpressure.

2.2 Flow Rate Units and Selection

Common units: L/min (liters per minute), Nm³/h (standard cubic meters per hour)

L/min is commonly used in medical oxygen tanks and small-scale applications.

Nm³/h is recommended for centralized supply of oxygen to industries and bottled oxygen filling systems.

Recommended Redundancy Factor: It is recommended to match compressor specifications according to the peak flow rate plus 10% to 20% of the redundancy space, to avoid overflow or frequent start/stop of loads. or frequent starting and stopping.

✅ Conversion reference:

1 Nm³/h ≈ 16.67 L/min

e.g.: an ICU ward with 30 beds, the average demand of each bed is 5L/min, the total flow rate of the system should be ≥ 2500 L/min ≈ 150 Nm³/h

2.3 Oxygen suitable materials and material safety

Oxygen is a strong oxidizing gas, and some of the materials will be oxidizing and fire risk

Prohibited materials: lubricating oil, organic plastic, carbon steel seals should not be used. Carbon steel seals

Recommended materials:

Piping and valve body: stainless steel (316L/304) or aluminum alloy pipe

Seals and gaskets: PTFE (polytetrafluoroethylene), special ceramic valve seat

✅ Medical applications must comply with CE or ISO 13485 equipment safety standards; industrial applications are recommended to be configured in accordance with the ASME/GB/T pressure vessel class.

2.4 Cooling Method

High temperature is associated with oxygen compression, which requires an effective cooling system to ensure safe operation and stable performance.

| Cooling Method | Applicable conditions | Features |

| Air Cooling | Well-ventilated, medium loads | Simple structure, wide applicability, easy maintenance |

| Water Cooling | Long-term, high loads, continuous operation | High heat dissipation efficiency, quieter operation, but need to be equipped with water supply and drainage system. |

Suggestions:

For glass furnaces, plateau sites or high-temperature and humid areas in the south, water-cooled compressors are recommended.

For flexible deployments such as mobile charging trucks and emergency systems, air-cooled compressors are preferred.

3. Selection of compression and lubrication type

In the oxygen compression system, the structure and lubrication type of the compressor have a direct impact on its safety, maintenance cost and application scenarios. Since oxygen is highly inflammable, if there are oil impurities, leakage or improper contact in the equipment, it is very easy to cause combustion or explosion. Therefore, the selection of compressors should strictly follow the three core criteria of “oil-free, clean and sealed”.

Compression type comparison table:

| Type | Principle features | Applicable Scenarios |

| Oil-free piston | Mature structure, easy maintenance, lubricant-free design | Medical Center Oxygen Supply, Bottle Pressurization, Small Industrial Centralized Filling |

| Diaphragm | Gas does not contact the transmission mechanism, high gas tightness, zero leakage, suitable for high pressure and high purity | Ultra High Pressure Oxygen Filling (200~400bar), Military/Aerospace Oxygen, Laboratory |

| Screw (for air) | Gas direct contact with lubricant, high compression efficiency, but not suitable for oxygen systems | Only for normal air compression, not for any oxygen system! |

Precautions and safety tips:

It is strictly forbidden to use ordinary oil-lubricated compressors for oxygen compression!

Lubricating oil in the high-pressure oxygen environment will undergo intense oxidation reaction, there is a risk of fire, deflagration and even blow up the machine.

Although diaphragm compressor has high cost and complicated structure, it has the absolute safety advantage of “gas does not contact with mechanical moving parts”, and it is the only recommended structure for oxygen ultra-high-pressure bottling (e.g. 200 bar).

Oil-free piston compressor is the mainstream solution for low and medium pressure medical/industrial oxygen, and is recommended for daily use from 10 to 200 bar.

| Application Scenarios | Recommended Compression | Pressure band reference |

| Medical Oxygen Bottling (small/community hospitals) | Oil-free piston type | 100~150 bar |

| Oxygen Supply for Industrial Ozone Equipment | Oil-free piston type + anti-oil return filter module | 10~50 bar |

| Hyperbaric Oxygen Cylinder Filling Stations / Oxygen Trading Stations | Diaphragm type + four-stage pressurization | ≥200 bar |

| Laboratory/Aerospace/High Purity Analytics | Double diaphragm compression + precision filtration + oxygen content monitoring | ≥300 bar |

| General Compressed Air Uses | Screw or oil-lubricated piston type | Not suitable for oxygen! |

4. Safety Standards and Certification Requirements

Oxygen compressors must be selected to meet a number of industry safety and international certification standards to ensure safe operation in high pressure, high purity, combustion assisted environments. The following are the main dimensions of safety compliance:

Material explosion-proof standards:

All piping, valves, cylinders and seals that come into contact with oxygen must be made of oxygen-resistant materials:

Stainless steel 316L / Aluminum alloy anodized

Meet GB/T 34540, ASTM B265, ISO 11120, etc.

Coatings and sealants must not contain flammable substances such as grease, chlorides, etc.

Electrical/Explosion-proof design:

If used in chemical plants, oxygen tanks, hazardous material warehouses, etc., it should be used with:

Ex explosion-proof marking (e.g., ExdIICT4)

Anti-static structural design, grounding resistance ≤10Ω

Anti-flameback protection valve + flame arrester + blowout vent

Medical/Industrial certifications (adapted to the scenarios):

Medical: CE, ISO13485 (medical device quality system), YY/T 0298 Industrial: PED (PED), YY/T 0298, etc. 0298

Industrial: PED (Pressure Equipment Directive), ASME (American Standard Vessel Approval)

5. Intelligent control and system matching

Intelligent control capability is one of the core parameters for high-end oxygen compression system to improve stability, efficiency and remote collaboration capability.

Control Logic Design:

Recommended configuration PLC (Programmable Logic Controller) + Touch HMI

Realize closed-loop control of compression tempo, flow rate, over-/under-pressure protection linkage;

Supports Chinese and English operation interface, authority grading, fault record keeping.

Whether to support remote monitoring / data upload:

Remote parameterization: control of air pressure, start/stop strategy, maintenance cycle prompts;

Alarm notification: oxygen concentration below the threshold (eg, 90%) can be linked to automatically cut the source;

Log management: daily operating parameters, energy consumption curve exported to Excel or API interface.

Compatibility with upstream equipment:

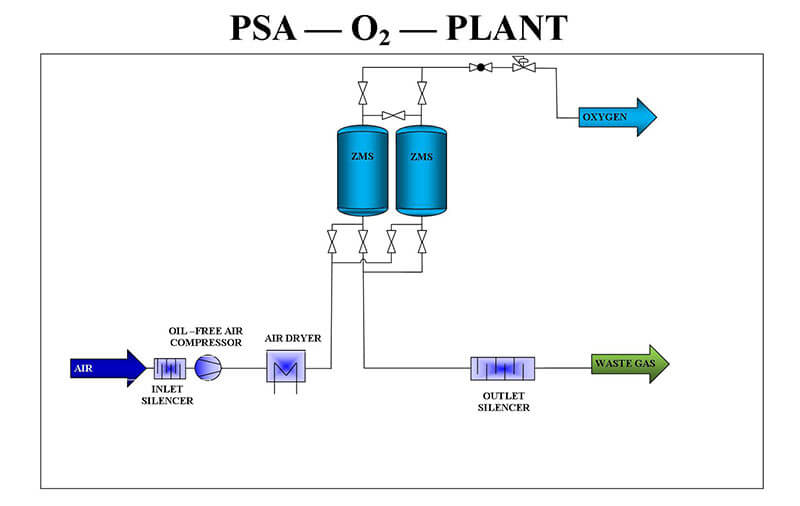

Linkage with oxygen generator (PSA/VPSA): whether to support analog signal input/output (4~20mA/485 Modbus RTU)

Docking with hospital gas station/factory energy center: whether to support MES/SCADA system linkage to meet the needs of intelligent diagnosis and energy statistics.

6. Ease of Operation and Maintenance and Life Evaluation

Long-term operation and maintenance cost is one of the core elements affecting the ROI (Return on Investment) of enterprises using oxygen compression equipment.

Examine the component life and maintenance frequency:

| Core Components | Regular life | Replacement Cycle Recommendations |

| Piston seals | 6000~10000 hours | 1~2 years depending on operating conditions |

| Diaphragm assemblies (e.g. diaphragm machines) | 8000~12000 hours | Periodic disassembly and inspection is recommended |

| Cooling system (air/water cooled) | Long-term stable operation | Note condensate drainage and anti-freezing measures. |

Suggested configuration: automatic temperature protection + water-cooling failure alarm + bearing lubrication timer

System level evaluation dimensions:

Does it support operation log analysis? Predictable aging of key components;

Modularized quick-disassembly design for wearing parts;

One-stop service of “annual inspection + remote diagnosis + spare parts delivery”?

Suggestions for comparison of actual cases:

Compare the PSA system compression module used by a large hospital for 5 years, with regular replacement of filter elements + the whole machine not dismantled;

Compared with the traditional domestic oil-lubricated screw machine, the energy consumption is reduced by 25%, and the alarm rate of the equipment is reduced by 60%.

7. Selection Checklist and Practical Advice

Before formally purchasing an oxygen compressor, the user needs to comprehensively evaluate the following key parameters, taking into account the usage scenario, process requirements and site conditions:

✅ Five parameters to be clarified before selecting an oxygen compressor:

Target Gas Pressure and Flow Rate

Is it 10 bar, 20 bar, 30 bar or higher pressure?

Is it a continuous oxygen supply, pulse load or peak fluctuation demand?

Upstream Oxygen Supply Equipment Type

PSA Oxygen Generator: Output pressure is mostly 0.3~0.6MPa

VPSA Oxygen Generator: Close to atmospheric pressure, higher compression ratio is required

Liquid Oxygen Storage Tanks: Often paired with Oxidation Reactor or Medium Pressure Process Section

Installation Site Limitations

Space (Compressor Volume, Cooling Paths)

Ambient Temperature & Humidity (High Temperature / Cold / Seaside / Plateau)

Are the Ventilation Conditions Adequate to Support Air-Cooled Heat Dissipation?

Operation Load Mode

Is it for 24-hour continuous operation, heavy load startup/frequent start/stop

there any need for interrupted backup (e.g., UPS, standby bottle set)

intelligent joint control function required

it required to be equipped with PLC/SCADA interface

it equipped with oxygen concentration/temperature/vibration sensor acquisition and alarm function

Recommended Scenario Selection Suggestion Table:

| Application Scenarios | Recommended Compressor Types | Recommended pressure range | Cooling required or not |

| Medical flow buffering (e.g. small gas stations) | Oil-free Piston | 10~20 bar | Air-cooled/Water-cooled |

| ICU centralized oxygen supply (medium pressure) | Oil-free Diaphragm + Tank | ≤10 bar | Water-cooled preferred |

| Industrial ozone systems (oxygen source gas) | Diaphragm or Piston Booster | 15~30 bar | Air-cooled |

| Glass combustion systems/metal smelting | Diaphragm or Screw Medium Pressure | ≥15 bar | Water-cooled recommended |

Remarks:

All types of compressors should be clearly indicated as “suitable for oxygen”, and use oil-free lubrication structure or full isolation design;

Industrial high-pressure system preferred diaphragm or two-stage compression structure;

Medical systems need to be matched with low noise, low vibration, with centralized alarm function equipment.

Practical selection suggestions:

Flow calculation suggestions: +15% redundancy on the basis of actual demand to cope with fluctuations in the oxygen source;

Cooling method preference rules: If continuous operation >8 hours or room temperature >35°C, water cooling is preferred;

Recommended materials for compression section: Stainless steel/aluminum alloy/PTFE coated material is recommended to ensure that it is oil-free and corrosion-resistant;

Intelligent functions: Oxygen concentration/temperature on-line detection + current abnormality alarm module is recommended to enhance the safety linkage.

Conclusion

The selection of oxygen compressor is not only a comparison of parameters, but also a comprehensive weighing of safety, adaptability and long-term reliability. Different application scenarios (e.g. medical oxygen supply, glass furnace, sewage oxygen enrichment aeration, etc.) put forward completely different requirements for pressure level, flow range, material explosion-proof level, intelligent control interface and other indicators. Users are advised to scientifically evaluate the selection logic based on the four dimensions of “operating conditions × technical parameters × certification norms × automation integration”, and not to equate oxygen compressors with ordinary air pressure equipment and ignore the potential risks.

MINNUO specializes in gas system solutions, providing a portfolio of oil-free oxygen compressors ranging from 3 to 300Nm³/h, supporting customized selection, diaphragm/oil-free piston/integrated compression structure, and possessing many certificates and qualifications such as CE/ISO, which are suitable for hospitals, plateaus, high temperatures, and industrial special working conditions. We also provide remote commissioning support, system linkage configuration and selection guidance.

sales2:+86 17506119168

sales2:+86 17506119168