As PSA oxygen generation system is widely used in hospitals, factories, cold chain warehousing, glass manufacturing and other industries, the process of installing the equipment is not only the first step of the project, but also has a direct impact on the purity, safety and operational stability of the subsequent system. Compared with the traditional gas source method, PSA oxygen generation system has higher requirements on environmental conditions, interface configuration and commissioning, so scientific planning of each step of the action to install is especially critical.

Many users often face the problems of “how to select the location and arrangement”, “whether additional drainage pipes are needed”, “how to link the electrical control system” after the equipment purchase is completed, “How to ensure the safety of the initial operation” and other specific issues. This article will focus on these common questions, and systematically explain the complete installation chain of PSA oxygen generator from site assessment, power supply preparation, module installation, commissioning verification to remote linkage, etc., to help users avoid common mistakes and improve deployment efficiency.

If you are planning to install a medium-sized or large PSA system, or are upgrading your old oxygen generator system, we suggest you continue reading the following article, as we will combine real cases with practical advice to bring you comprehensive and practical installation guidance.

1.Pre-Installation Checklist

Before installing PSA oxygen generator, whether the site preparation is in place or not will directly affect the stability of the system operation and the efficiency of the later maintenance. It is recommended to complete the following preparations before entering the construction site or technical docking:

1.1 Requirements for site and infrastructure

Equipment area and layout planning: It is recommended to reserve at least ≥2 square meters of flat hard ground for the installation of the main engine, air compressor, storage tank and other modules, avoiding extruding and stacking which may lead to obstacles in operation or poor heat dissipation.

Ground environment requirements:

The ground is flat, moisture-proof and shock-proof to avoid tower deflection due to unstable foundation;

It is recommended to lay non-slip floor tiles or with buffer layer, especially suitable for hospitals or chemical industry areas.

Ventilation and heat dissipation conditions: good natural ventilation should be ensured around the equipment to avoid heat buildup affecting the performance of the air compressor and cold dryer.

Reservation of interfaces with peripheral systems: arrange oxygen terminal pipe network, power lines, drainage pipes, etc. according to the drawings, pay special attention to: the distance from the power distribution room, exhaust windows and walls should be in accordance with the electrical and safety standards.

1.2 Evaluation of power supply and energy consumption

Power supply access method: confirm whether it is 220V/380V three-phase power, and configure corresponding cables, circuit breakers and grounding wires if necessary.

Power accounting: Total the total power of the host, air compressor, PLC control box, cold dryer, etc. Generally, the total power of the PSA system is 1-20kW, and the transformer on site should have sufficient capacity.

Emergency backup plan:

UPS is recommended to be configured for smooth shutdown of the control system after power failure;

For important medical/remote scenarios, it is recommended to consider parallel backup of diesel generator sets to improve the guarantee of continuous oxygen supply.

1.3 Other Supporting Conditions

Water Source and Drainage System:

If the system contains a cold dryer or a suction dryer, it is necessary to set up a cooling water circuit and a drainage port;

It is recommended to use an independent drainage pipe with a filtering and sedimentation function to prevent blockage and pollution.

Piping connections and accessories:

Oxygen output should be connected to the buffer tank/oxygen main pipe;

If the site is a multi-terminal gas supply, the location of the pressure reducing valve, diverter valve and check valve should be planned ahead of time;

The exhaust outlet is recommended to be connected with a hose and guided to the outdoor area, so as to avoid the accumulation of oxygen concentration in the oxygen generating room.

Grounding and lightning protection:

All equipment chassis must be well grounded;

It is recommended to configure a power surge protector (SPD), especially for high thunderstorm areas or plateau sites.

Practical advice: If the project involves renovation or reconstruction of the premises, it is recommended to use CAD engineering layout drawings for prequalification, and at the same time, you can contact the manufacturer’s technical support (e.g. MINNUO) to provide personalized interface diagrams and equipment entry conditions to avoid reworking and mismatching.

2. Core Installation Steps

The on-site installation of PSA oxygen generation system is not simply “plug and play”, but covers a series of processes from equipment acceptance, structural positioning, gas circuit configuration to electrical wiring. Standardized installation process can significantly reduce the risk of commissioning, improve the long-term operation of the system safety and stability.

2.1 Equipment unpacking and inspection

Confirmation of equipment parts list:

Main machine (including adsorption tower, valve group, controller)

Air compressor, gas storage tank, cold dryer (if any)

Precision filters, PLC electric control box, distribution cabinet and other auxiliary equipment

Appearance and transportation damage inspection:

Verification of the machine body for any bumps, deformation, paint loss, etc.

Check the control panel, instrumentation connectors for looseness and breakage

Inventory of spare parts and accessories, and technical documents (such as manuals, wiring diagrams)

It is recommended to use the standard “Unpacking and Acceptance Record Sheet”, which should be filled in item by item and signed by Party A/installer.

2.2 Positioning and fixing of each module

Suggested order of equipment positioning:

Air compressor → Gas storage tank → Air dryer → Precision filter

Final connection to PSA mainframe (double tower structure)

Requirements for foundation positioning:

Refer to the interface layout provided by the manufacturer to accurately place the position of each piece of equipment.

The storage tank and mainframe shall be strengthened with M10~M12 footbolts and concrete foundations to ensure seismic resistance and solidity.

All equipments shall maintain a gap of 5~10cm to facilitate subsequent maintenance. All equipments should keep a gap of 5~10cm, which is convenient for subsequent maintenance.

✅ Tips: The mainframe should be avoided from direct sunlight or dead angle against the wall, which is good for heat dissipation and maintenance.

2.3 Piping Connection

Piping Connection Principle:

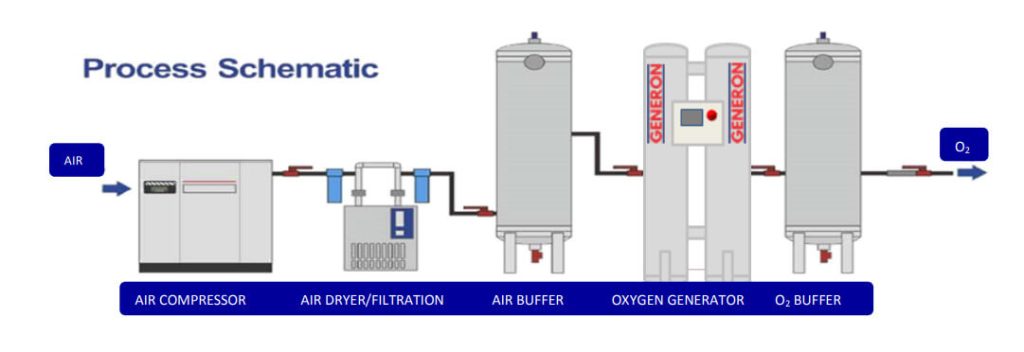

Air Compressor → Storage Tank → Filter → Drying Treatment → PSA Main Unit Inlet

PSA Main Unit Outlet → Buffer Tank → Gas Network or Manifold

Suggested Piping Material:

Seamless Stainless Steel Pipe 304 / Aluminum Alloy Oxygen Pipeline (Pressure Level ≥ 0.8MPa)

All connections are made with double ferrule fittings or welded flanges to prevent leakage of oxygen

Tightness Test:

It is recommended to carry out 0.6MPa air pressure holding test ≥ 1 hour after completing the takeover.

Test equipment including: soap and water airtightness method, pressure gauge pressure record, electronic leak detector (recommended by the hospital)

✅ Oxygen outlet should be equipped with a check valve + safety valve, to prevent back-up and overpressure of the system.

2.4 Electronic control system wiring

Key wiring points:

PLC control box → solenoid valve → air compressor/cooler start/stop circuit

Distribution box connected to the signal terminal board, alarm module, oxygen concentration detector and other signaling equipment

Distribution and grounding specifications:

main power supply according to the system’s power configuration of three-phase five-wire system, it is recommended that the independent switch + grounding protection

medical scene recommended configuration UPS and overload protection device

All wiring to be worn through the trunking or protection sleeve, clearly labeled, and prohibited overlap All wiring must be routed through a wire groove or protective sleeve, clearly labeled, and prohibited from being exposed

✅ After installation, it is recommended that an electrician conducts an “insulation resistance test + grounding resistance test” to ensure compliance with GB electrical standards.

3. Commissioning & Test Run

Start-up commissioning of a PSA oxygen generation system is not only a “routine procedure” before system operation, but also a key link to ensure stable gas production and safe and compliant operation. It is recommended to be carried out by the manufacturer’s engineers or a professional team with experience in electrical/gas circuits according to the following steps.

3.1 Start-up commissioning sequence

Suggested start-up sequence for each unit:

1. air compressor → 2. air dryer / adsorption dryer → 3. precision filter → 4. PSA mainframe (including PLC system)

Energized check items:

Is the power supply of the control system stable, and does the touch screen / PLC respond normally?

Is the direction of the motor running and the indicator correct?

Observation of the system operating parameters:

Air compressor pressure setting (recommended 0.7~0.8MPa) PSA mainframe (recommended 0.7~0.8MPa) 0.8MPa)

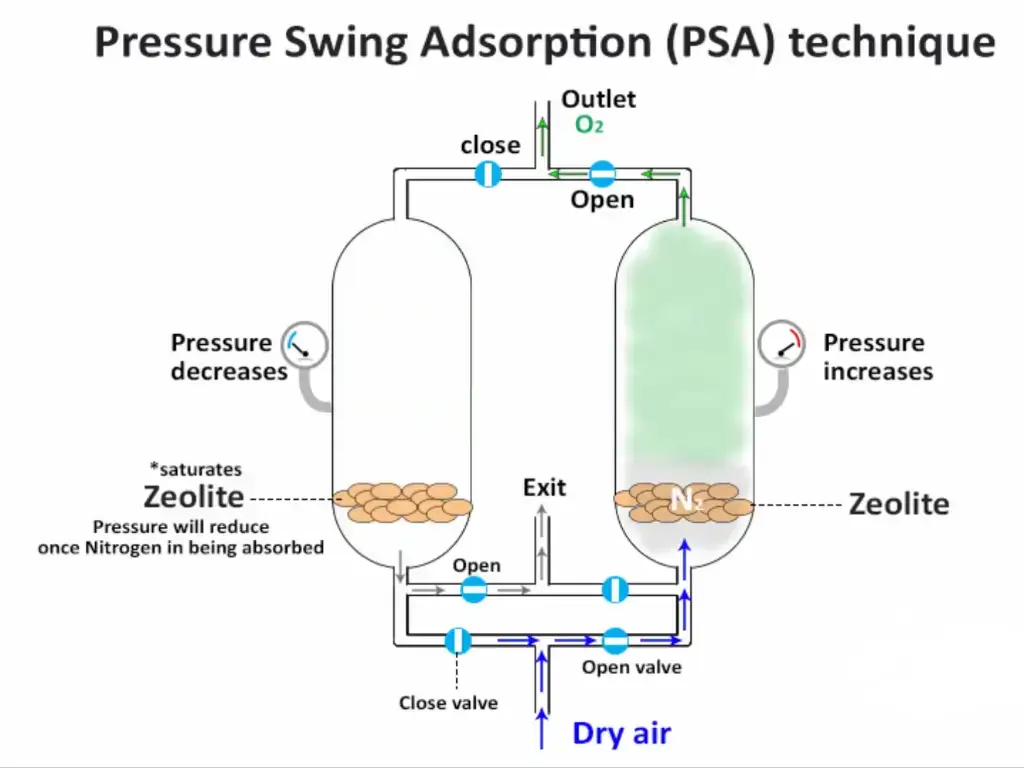

Whether PSA adsorption/desorption cycle is switching stably

Whether oxygen outlet pressure, flow rate and concentration reach the set value

Warmth Tips: It is recommended to set low load gas production for the first time operation, and then gradually transition to full load operation.

3.2 Oxygen Purity Verification

Instrument Configuration:

It is recommended to use on-line oxygen concentration analyzer with ±0.5% accuracy (recommended to be installed on PSA outlet line)

Compliance Standard:

Medical use: 93%±3% output should be stabilized (in accordance with YY/T 0298)

Industrial use: ≥95% or ≥99.5% according to the actual need (partially adjustable system)

Residual Gas Path Inspection:

Whether nitrogen discharge from PSA tower is smooth or not

Whether the nitrogen/residual gas path is set with silencer or discharge pipe

Whether the multi-tower switching beat setting is accurate

Can be combined with the online concentration recording module, and tracked for 1~2 hours to determine whether the purity fluctuation is stable.

3.3 Safety interlock test

Trigger test items:

Whether the host machine stops gas supply and automatically cuts off power after the emergency stop switch is pressed

Whether the alarm is triggered when the pressure is too high/low (>0.6MPa or <0.2MPa)

Whether cut off/standby oxygen switching is triggered when the alarm value of the low oxygen concentration is set to <90%

Whether the system automatically shuts down the exhaust gas/shut off the solenoid valve when a fault such as power failure or interruption of the gas source is simulated

Discharge gas Confirmation of protection function:

Whether the residual air is discharged smoothly when the adsorption tower releases pressure (recommended to connect to the exhaust port or outdoor)

Whether the pneumatic valve and solenoid valve linkage switching is in place accurately

✅ Multi-level interlocking is recommended to be configured for medical applications, e.g., linkage with the UPS, power switching controller, and standby oxygen supply system.

4.Common Installation Mistakes to Avoid

PSA oxygen generator installation seems simple, but because it involves electrical control, gas fluid dynamics, automatic valve response and other modules, the slightest negligence may lead to a decline in the efficiency of oxygen production, purity does not meet the standards, and even frequent alarm shutdown of the system. The following are some typical mistakes summarized in practice and their corresponding preventive suggestions:

4.1 Neglecting the design of drainage path → leading to molecular sieve moisture absorption failure

Problem performance:

molecular sieve deliquescence, oxygen purity decreases rapidly

condensation inside the adsorption tower, resulting in incomplete adsorption and increased gas resistance

Precautionary measures:

Make sure that the chiller/take-up dryer is complete before installation, and replace the drainage filters regularly

automatic drainer should be added at the bottom of the adsorption tower or the gas tank, and directed drainage to the bottom of the adsorption tower, and the automatic drainer should be installed at the bottom of the adsorption tower. The bottom of the adsorption tower or gas storage tank should be equipped with automatic drainer and directed to the safe drainage ditch.

It is recommended to use dew-point meter to monitor the humid environment and track the drying effect for a long time.

4.2 Cable wiring is messy → interfering with PLC control signals.

Problems:

False alarms, false linkage of the equipment.

Touch-screen jamming or malfunctioning, or even host power failure.

Precautionary measures:

All signal lines (PLC control, oxygen concentration probe, valve feedback) should be laid separately from the power lines.

The high and low voltage lines should be routed separately in the control cabinet to avoid the rise of adsorption gas resistance. All signal lines (PLC control, oxygen concentration probe, valve feedback) should be laid in separate lines from power lines. High and low voltage lines in the control cabinet should be routed in separate layers to avoid interfering with each other.

It is recommended that shielded cables be used for signal cables, especially in the high-interference environment of the factory.

4.3 Poor sealing of air pipe clamps → Oxygen leakage affects the purity.

Problems

Oxygen purity detected at the outlet of the PSA system is lower than the threshold.

Oxygen piping has a hissing sound, which affects the stability of the piping network.

Precautions

Conduct a “soap airtightness test” on each pipeline during installation.

Use a torque wrench when tightening clamps to avoid insufficient torque.

Important gas pipelines should be equipped with double-layer anti-disconnecting quick couplings or welded encapsulation.

4.4 Failure to configure buffer tanks → Oxygen fluctuates greatly, affecting the stability of end-use equipment.

Problems:

Significant fluctuations in operation of end-use loads such as packaging machines and respirators, and frequent alarms in the PSA tower. Obvious, frequent alarms

Frequent switching of PSA tower leads to unstable pressure and uneven oxygen concentration.

Precautionary measures:

PSA system is recommended to be equipped with ≥300L oxygen buffer tanks, which can effectively suppress the instantaneous flow fluctuations.

The system with gas flow rate of ≥20Nm³/h is recommended to be partitioned and distributed with tanks (front + rear).

If the terminal is connected to critical loads, such as ICU/operating room, the equipment should be added to the automatic switching device of the cylinder group.

5. Remote Monitoring & Integration

In modern medical, industrial and environmental applications, oxygen systems are no longer operating in an “island”, but increasingly need to realize real-time data interaction and intelligent linkage with the upper management platform. Especially when oxygen equipment is deployed in distributed scenarios, unattended areas or key business systems, remote monitoring and system integration capabilities have become essential technical support.

5.1 System compatibility: whether to support access to SCADA / MES / hospital master control platform

Medical industry scenarios: need to dock the hospital gas station management system to realize real-time view of the oxygen supply status in key areas such as ICU, operating rooms, etc.;

Industrial manufacturing scenarios: docking the MES / SCADA platform for production line intelligent scheduling, energy consumption statistics, and equipment operation analysis;

Cloud platform / third-party Internet of Things (IoT) platforms : Access through standard communication protocols (e.g. MODBUS-TCP, RS485) to realize centralized and unified management of multiple devices.

✅ Recommended Configuration:

supports MODBUS, PROFINET, Ethernet/IP and other industrial bus protocols;

supports remote port opening, which is convenient for docking with IT operation and maintenance system;

can extend OPC UA gateway or MQTT IoT components to meet the needs of Industry 4.0 or smart hospital.

5.2 Control and Setting Functions: PLC+HMI Intelligent Control System

Human Machine Interface HMI: 7~10 inch industrial touch screen, supporting Chinese operation interface, intuitive and convenient parameter setting;

PLC program control: control adsorption switching logic, gas flow, concentration alarm linkage, etc.;

support remote parameter adjustment (such as purity threshold, operation time period, exhaust mode, etc.);

Automatic recovery program in case of power failure/line loss, ensuring the equipment to be able to meet network failure. The automatic recovery program in case of power failure/dropout ensures that the equipment can still run independently and safely in case of network failure.

5.3 Online data monitoring and uploading

Real-time monitoring: oxygen concentration (±0.5% accuracy), output pressure, total flow, operation status;

Alarm triggering: such as oxygen concentration <90%, motor over-temperature, valve failure, automatic alarm + linkage switching of standby gas source;

Data logging and exporting: reports can be exported hourly/dayly/monthly for hospital quality control or enterprise energy efficiency accounting;

Cloud data backup (optional): Support connecting to remote server via 4G/Ethernet to realize historical running data backup and remote audit.

✅ Supporting Suggestions:

Recommended to use HMI devices with SD card/U disk data backup function;

Medical customers can cooperate with the printing module to directly export the concentration diary;

Industrial customers are recommended to connect to the local database or centralized SCADA system to meet the requirements of corporate compliance audit or ISO quality system.

| Functional requirements | Recommended Technical Configuration | Application Value |

| Access to hospital/factory system | Support MODBUS/Ethernet communication protocol | Realize unified supervision of platform and intelligent linkage of equipment |

| Off-site remote control and monitoring | PLC control + HMI touch screen + remote port opening | Reduce the frequency of manual maintenance and improve the efficiency of system response |

| Oxygen purity/flow rate/fault online view | Oxygen Concentration Sensor + Flow Meter + Alarm Module | Ensure the quality of oxygen supply and improve the level of medical safety |

| Historical data recording and uploading for backup | Data Export + SD Card/U Disk + Cloud Backup Service (optional) | Meet the quality control of hospitals, factory compliance audit and traceability |

6. Maintenance Handover

After the PSA oxygen generation system is officially put into operation, a scientific maintenance plan is the key to guarantee the long-term stable operation of the system and to maintain the purity and continuity of oxygen supply. After the installation and commissioning of the system is completed, a complete maintenance handover should be carried out between the manufacturer’s technicians and the user’s operation and maintenance party, including the replacement cycle description, regular inspection program confirmation and data transfer.

6.1 Replacement cycle of core consumables

Replacement cycle of molecular sieve: 8000~12000 hours

Molecular sieve is the key adsorbent material to realize oxygen and nitrogen separation, and its adsorbent efficiency gradually decreases with the use of time, so it is recommended to replace it in accordance with the number of operating hours or annual evaluation.

Filter cartridge (air filter, oil separator, precision filter): 4000~8000 hours

Filter cartridge clogging will affect the quality of air supply and compressor load, need to be replaced regularly and recorded.

Oxygen concentration on-line analyzer: It is recommended to calibrate the analyzer once a year

to ensure the accuracy of oxygen concentration detection ±0.5% to meet the medical/industrial safety requirements.

✅ Suggestion: Provide a “Consumables Replacement Reminder Form” or “Monthly/Quarterly Inspection Plan Template” by the manufacturer to facilitate the implementation of the plan by O&M personnel.

6.2 Daily O&M System Development Recommendations

Air compressor maintenance (oil change, fan cleaning, belt check)

Complete maintenance can be performed every 4000 hours as recommended in the manual.

Automatic drainage system function test

Check whether the drainage is smooth to avoid moisture entering the molecular sieve and causing adsorption failure.

Equipment operation data record

Record oxygen concentration, operating pressure, flow rate, number of alarms and other key indicators every day for trend analysis and early warning.

7. PSA Oxygen Generator for Biogas Production: A Specialized Application

Beyond common industrial and medical uses, PSA oxygen generators play a critical role in biogas upgrading and wastewater treatment. This section explains why on-site oxygen generation is a superior solution for these processes and what special considerations are needed for installation and operation.

7.1 Why Use PSA Oxygen for Biogas?

In biogas plants, oxygen is primarily used in two ways:

- Biogas Upgrading (to Biomethane): Oxygen is introduced into the raw biogas (containing H₂S, CO₂) to facilitate the Biological Desulfurization process. Specific bacteria use oxygen to convert toxic and corrosive hydrogen sulfide (H₂S) into elemental sulfur or sulfates, which can be easily removed. This protects downstream equipment and increases the value of the final biomethane.

- Wastewater Treatment Aeration: Oxygen is used in aeration tanks to support aerobic bacteria that break down organic pollutants, significantly improving treatment efficiency compared to using air.

Key Advantages Over Bottled or Liquid Oxygen:

- Cost-Effective: Eliminates recurring costs and logistical hassles of delivered gas.

- On-Demand Supply: Produces oxygen precisely when needed, ideal for continuous biological processes.

- Safety: Avoids storage and handling risks associated with high-pressure oxygen cylinders or cryogenic liquids.

- Purity Control: Oxygen purity (typically 90-95%) is ideal for biological processes, avoiding the inefficiency and potential hazards of using pure oxygen.

7.2 Special System Design & Installation Considerations

Installing a PSA oxygen generator for biogas applications requires attention to specific factors not always present in standard setups.

A. Site and Environmental Factors:

- Corrosive Atmosphere: Biogas plants often have ambient air containing trace H₂S and moisture. The air intake for the oxygen generator must be located in a clean, well-ventilated area upwind from digester or sulfur removal units. Consider installing an additional pre-filter with activated carbon to protect the compressor and PSA adsorbents.

- Hazardous Area Classification: Verify the zone classification of the installation site. While the oxygen generator itself is not typically placed in a hazardous zone, its electrical components and motors must be rated for the general industrial environment, and wiring should comply with local standards for potentially corrosive atmospheres.

B. System Integration and Piping:

- Integration with Biogas Process: The oxygen output must be fed into the biogas stream or aeration tank under controlled conditions. This usually requires:

- A mass flow controller (MFC) or a precise control valve to regulate oxygen injection rates based on H₂S concentration or biological oxygen demand (BOD).

- A static mixer to ensure thorough mixing of oxygen with biogas or wastewater.

- Piping Material: Stainless steel (316/316L) is strongly recommended for all oxygen piping within the biogas plant area due to its superior corrosion resistance against residual moist H₂S.

C. Safety & Control Interlocks:

- Oxygen Injection Safety: The system must have an automatic shut-off valve interlocked with the biogas compressor or blower. If the biogas flow stops, oxygen injection must immediately cease to prevent creating a flammable oxygen-rich environment in the pipeline or digester.

- Purity Monitoring: Continuous online oxygen purity analysis is crucial. A drop in purity could indicate a system fault and affect the biological process efficiency.

- Backup Plan: While PSA systems are reliable, consider a bypass line with a manual valve connected to a standby oxygen cylinder bank for emergency use during unforeseen maintenance.

7.3 Recommended Configuration & Checklist for Biogas Projects

| Aspect | Recommendation for Biogas Application |

|---|---|

| Oxygen Purity | 90-93% is typically sufficient and cost-effective for biological processes. |

| Pressure | Must be higher than the biogas pipeline or aeration tank pressure. Usually 0.5 – 2 bar(g) above the injection point is adequate. |

| Flow Control | Essential. Integrate with plant’s PLC/SCADA using a Mass Flow Controller (MFC) for precise dosing. |

| Air Intake | Install in a clean air location. Use a weather hood and a combined particulate/activated carbon pre-filter. |

| Material (Wetted Parts) | Stainless steel 316L for compressor aftercooler, air buffer tank, and oxygen piping after the generator. |

| Key Interlocks | 1. Oxygen flow linked to biogas flow. 2. Low oxygen purity alarm. 3. High discharge temperature alarm from air compressor. |

Pre-Installation Question Checklist for Biogas:

- What is the required oxygen flow rate (Nm³/h) for the designed H₂S load or BOD removal?

- Where is the cleanest possible location for the oxygen generator’s air intake?

- What is the pressure at the oxygen injection point into the biogas line or aeration tank?

- How will oxygen flow be controlled and integrated with the existing plant control system?

- Are all planned piping and valve materials suitable for a mildly corrosive environment?

Conclusion

The installation of PSA oxygen concentrator is not only a matter of equipment stacking and pipeline connection, but also a matter of system safety, oxygen purity and subsequent operation and maintenance efficiency. A standardized installation process should include site pre-assessment, power supply configuration, gas line and control system connection, commissioning and operation verification, and later maintenance handover. Especially in hospitals, plateaus and industrial heavy load scenarios, it is recommended that the initial installation be guided by an experienced professional team on site to ensure stable and efficient operation of the equipment.

As a professional supplier of PSA/VPSA oxygen generation system, MINNUO supports modular pre-assembly, remote commissioning assistance and after-sales inspection service, which is suitable for hospital ICU, operating room, welding workshop, aquaculture and other occasions. According to your oxygen flow, installation space and monitoring requirements, we can provide one-stop installation and configuration solutions and engineering support to help you build a safe, compliant and efficient oxygen generation system. Visit https://minnuogas.com for exclusive installation advice.

sales2:+86 17506119168

sales2:+86 17506119168