Introduction

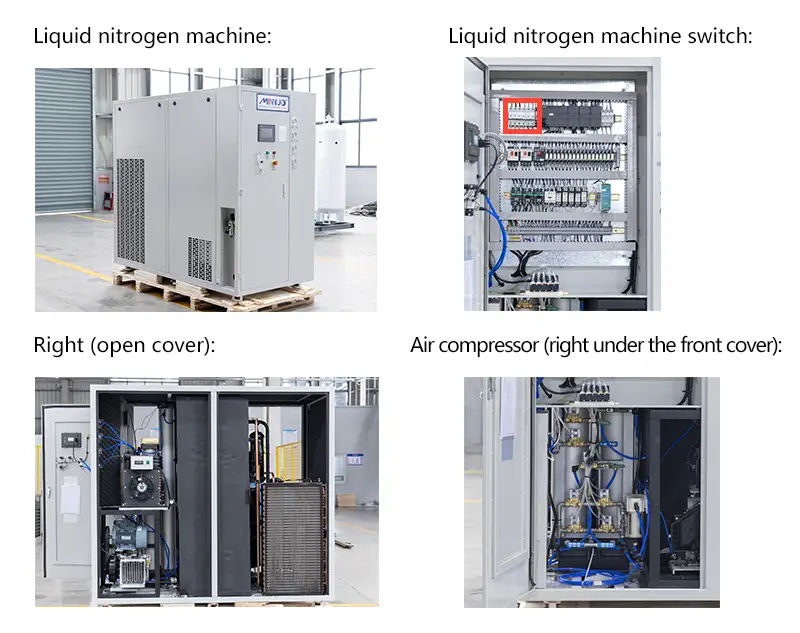

The automatic compact liquid nitrogen preparation system uses a pressure variable adsorption nitrogen generator (PSA nitrogen generator) to produce nitrogen from the air, which is liquefied into liquid nitrogen by a mixed working medium throttle chiller and stored in a liquid nitrogen Duva. The compact structure allows a continuous and accessible supply of liquid nitrogen. This article will focus on the installation matters of liquid nitrogen machines.

How to install and correct?

Connect the cable

- PDP (Distribution box): Ensure the correct circuit breaker with enough ampere (current) according to the electrical drawing.

- Three-phase power cable connection: U / V / W / N / PE to nitrogen generator and liquefier.

- There are no loose or broken connections. There are no exposed cables.

- Check all the connections according to the electrical diagram.

Note: The power supply of the liquid nitrogen machine is 380V / 50Hz / three-phase electricity.

Mechanical connection

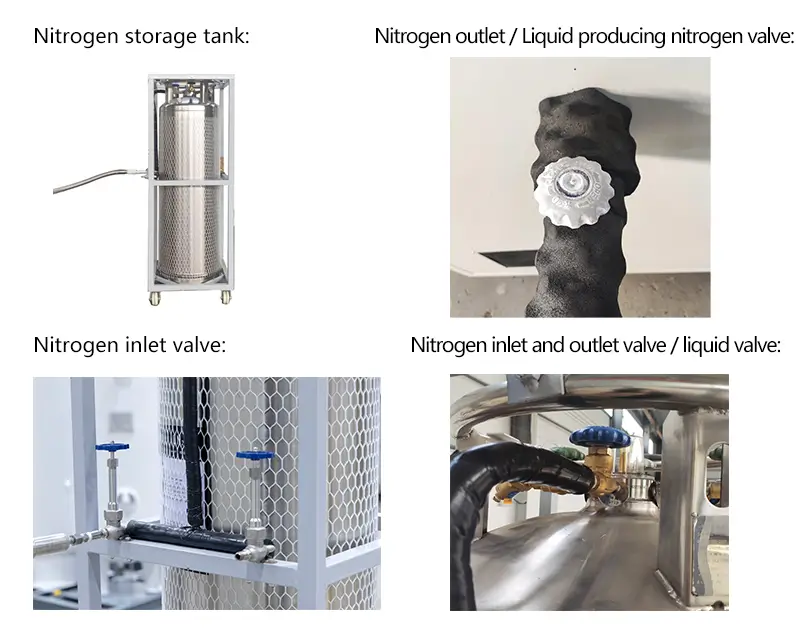

Connect the liquid nitrogen machine to the nitrogen storage tank with a special liquid nitrogen pipe.

- Ensure the nitrogen generator condensation port outlet is connected to the site drainage pipe.

- Ensure all the connections are correct, tight, and firm.

- Ensure all attached fittings are intact and in the correct orientation /position.

Foundation and ground

- Ensure the ground is flat, firm, and has enough bearing capacity.

- Ensure the ground is dry and clean and not easy to slide.

- No foreign body sundry. No water, no liquid.

Waste/condensate water drain pipes

Nitrogen generator discharge port

- Waste or condensate drainage should be directed outside from a cold dryer and air filter.

- Drains should be well prepared.

- You should observe local laws and regulations.

Machine room conditions

- Provide a dry and well-ventilated environment.

- Avoid placing in high temperature and high humidity environments.

- Install the equipment on clean, flat ground.

- Keep the distance around the equipment 40cm to ensure the average heat dissipation of the nitrogen generator air compressor.

- High-temperature environments and high humidity will cause a decrease in the gas production flow and pressure of the equipment and reduce liquid production.

- The nitrogen generator’s internal pipeline has high-pressure gas, do not remove it yourself.

- Do not discharge the compressed gas from the production port of the nitrogen generator directly into the air. This operation will cut the air compressor for a long time and affect the service life of the air compressor.

- The outlet pipe of the liquid nitrogen machine is at a low temperature. Please do not remove it by yourself to avoid frostbite.

- The compressor exhaust pipe inside the air and liquid nitrogen compressor is in a high-temperature state, so do not touch them.

- You must observe local laws and regulations about environmental health and safety.

How to conduct both local and manual test runs?

Air compressor

Check before startup: check the phase sequence.

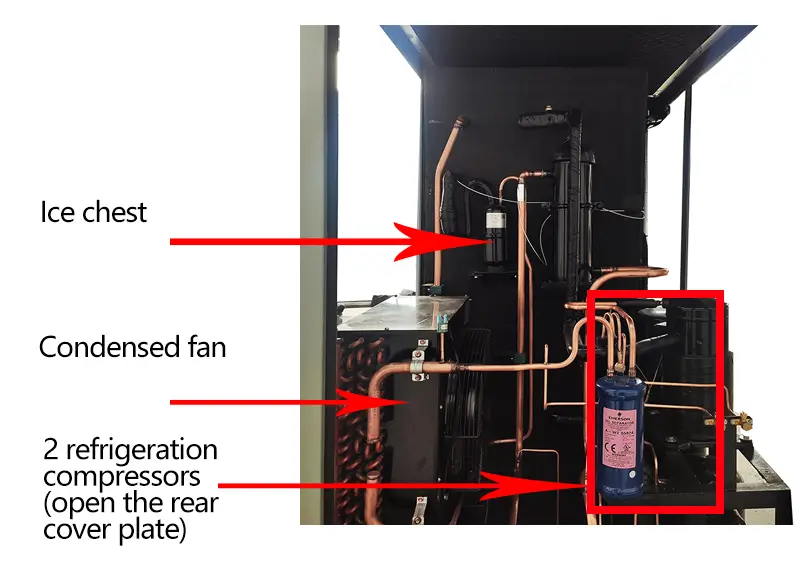

Refrigeration compressor

- Check before starting: if any, remove transport protection; power on.

- Learn all the warning labels on the refrigeration compressor.

- Power it up on the touchscreen, and keep it running.

- Check whether the automatic drainage is normal.

- Ensure that the ball valve on the outlet is fully open.

- Ensure that the refrigeration compressor is operating properly.

- Check and set the pressure set point (preset).

- Power on the touch screen and wait for the air compressor to start (if started, state on the air compressor icon on the HMI panel), and then

- Quickly shut down on the touch screen or press the emergency stop switch on the control cabinet to check the rotation direction of the motor. The rotation direction of the motor will be pointed in the same way as the arrow on the motor housing. If wrong, reconnect the power cord (phase order).

- starting up.

- The pressure of the air tank increases accordingly. Discharge pressure will quickly rise to the unloading setpoint.

- Check that the cooling fan is operating properly.

- Keep running.

Nitrogen generator

Note: The factory has been adjusted, do not move

- Inlet open. The nitrogen outlet valve is closed.

- The pilot air pressure relief valve set point is 0.3-0.5MPa.

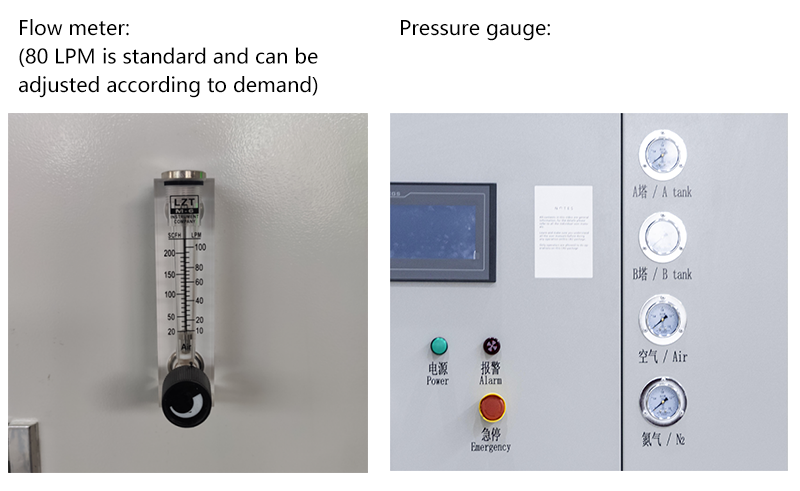

- By observing the pressure gauge, the pressure of the adsorption tower rises.

- The pressure inside the regeneration tower is close to 0.

- A small flow comes out of the silencer.

- The nitrogen pressure rises gradually in the nitrogen buffer tank.

- Then it enters the homogenization process, and the pressure of the two adsorption towers is almost the same at the end.

- When the regeneration process and the adsorption process are switched between the two adsorption towers, the large flow rate flows out from the muffler and gradually drops to almost 0

- Open the main nitrogen outlet slowly, set the nitrogen pressure reducing valve at 0.6-0.85MPa (best 0.85MPa), and check the oxygen meter sample gas

- Flow rate, check/adjust the nitrogen flowmeter.

- Slowly open the N nitrogen outlet valve until the N nitrogen flow rate is 18 LPM.

- Nitrogen purity should rise rapidly from 79.9% to 99 and gradually to 99.9%.

- Check the air/nitrogen relief valve/manual filter drain.

- Keep running.

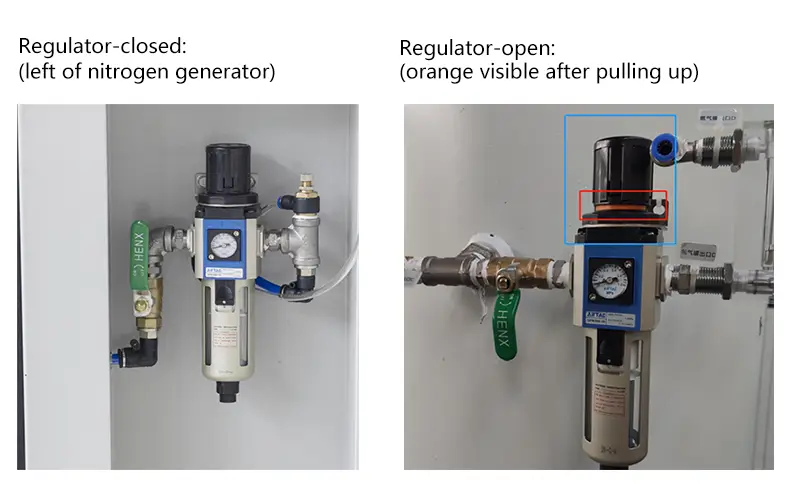

- Method to use the pressure regulating valve:

Pull the knob up, and pull up clockwise, counterclockwise. After the adjustment, press the knob to reset.

Nitrogen gas storage tank

Use of booster valve:

Pull the button down, turn the valve to close clockwise, and open counterclockwise.

Note: The factory has been adjusted, do not move

Booizer valve-open state: (lower button below)

Nitrogen liquefier

- The power supply cables shall be connected correctly connected-U / V / W / N / PE.power on. The emergency stop button has popped up.

- Connect liquid nitrogen outlet pipe to nitrogen storage tank nitrogen inlet valve (snap plug and hose).

- Open liquid nitrogen outlet hand valve (5-10°)

- Select the user name at the liquefier man-machine interface, enter the password, and start up.

Leak inspection

Open the front cover of the liquid nitrogen machine (test all connections):

- Check the air tightness of all connections using soapy water or other tools. If there is a leak point, after the shutdown, the pressure release, add solid, and drain. Be careful with electronic devices, do not damage them with water.

- Visually check for leaks or liquid nitrogen, and mark if there are any. After the shutdown, pressure is released, the liquid is emptied, and leakage is treated.

Commissioning

- If 40-80 minutes after startup, liquid nitrogen production begins.

- Adjust the nitrogen flow rate according to the instructions if the nitrogen flow rate is insufficient.

- The startup and debugging ends.

- Adjust the nitrogen flow rate and liquid nitrogen outlet valve, control the nitrogen pressure between 7.5-8.5, and preferably stabilize at 8-8.5. It also has to check the purity.

Conclusion

Installing liquid nitrogen machines is critical in various industries, including food, pharmaceutical, and scientific research. To ensure the safe and efficient handling of nitrogen, attention must be paid to the installation. Besides, a properly installed and maintained liquid nitrogen machine can help companies improve efficiency, reduce waste and improve product quality, making it a valuable investment.

sales2:+86 17506119168

sales2:+86 17506119168