Nitrogen gas, or N₂, is a key element in many industries due to its inert properties and versatility. From chemical manufacturing and food processing to agriculture, healthcare, and diving, nitrogen plays a critical role in improving efficiency, safety, and product quality.

Nitrogen gas can be produced using methods such as air separation, pressure swing adsorption (PSA), and membrane separation. Each method has its own advantages and is suited to different industrial applications. Understanding these methods and their applications helps industries like chemicals, food processing, agriculture, healthcare, and diving optimize nitrogen usage efficiently and safely.

In this article, we’ll explore the different methods of producing nitrogen gas, the equipment involved, and the factors to consider when choosing the right production method. By understanding these aspects, professionals across different fields can optimize their nitrogen usage and ensure a reliable supply for their specific needs.

What is Nitrogen Gas

Nitrogen gas, or N₂, is a colorless, odorless, and tasteless gas that makes up about 78% of the Earth’s atmosphere. It consists of two nitrogen atoms bonded together, forming a diatomic molecule. Nitrogen is relatively inert, meaning it doesn’t easily react with other substances, making it extremely useful in various industrial applications.

Nitrogen is a non-metal and is the seventh most abundant element in the universe. It is found in all living organisms, primarily in amino acids, proteins, and nucleic acids (DNA and RNA). In its gas form, nitrogen is inert and doesn’t support combustion, making it a crucial element for creating safe and stable environments.

The Importance of Nitrogen Gas

Nitrogen is important for several reasons. In the chemical industry, it’s used to create ammonia for fertilizers, which is essential for modern agriculture. The Haber-Bosch process, which synthesizes ammonia from nitrogen and hydrogen, revolutionized agriculture by providing a stable supply of nitrogen-based fertilizers. In the food industry, nitrogen is used for packaging to preserve freshness and extend shelf life. Nitrogen flushing is a common technique to remove oxygen from packaging, preventing oxidation and spoilage.

In the medical field, nitrogen is used to preserve biological samples and create a controlled atmosphere for certain procedures. Liquid nitrogen is used in cryopreservation to store cells, tissues, and reproductive cells at extremely low temperatures. Additionally, nitrogen is used in electronics manufacturing to create an inert environment for sensitive components, preventing oxidation and contamination. It’s also used as a safe environment for diving operations, reducing the risk of nitrogen narcosis and oxygen toxicity at deep depths.

Applications of Nitrogen Gas

Chemical Industry: Nitrogen is used to create ammonia, a key ingredient in fertilizers. It also serves as a blanketing gas to prevent oxidation during chemical reactions. In petrochemical industries, nitrogen is used for purging pipelines and equipment, ensuring that no flammable gases are present.

Food Industry: Nitrogen is used to package foods in a nitrogen-rich environment, preventing spoilage and extending shelf life. Nitrogen freezing is also used to quickly freeze food products, maintaining their texture and nutritional value.

Agriculture: Nitrogen fertilizers are essential for crop growth, providing the necessary nutrients for plants. Urea, ammonium nitrate, and ammonium sulfate are common nitrogen fertilizers that enhance soil fertility.

Medical Field: Nitrogen is used to preserve biological samples, for cryosurgery, and to create inert atmospheres for certain medical procedures. Cryosurgery, which uses liquid nitrogen to destroy abnormal tissues, is commonly used in dermatology and oncology.

Diving: Nitrogen is used in gas mixtures for diving to prevent oxygen toxicity at deep depths. Trimix and nitrox are popular gas mixtures that include nitrogen, reducing the risk of decompression sickness and nitrogen narcosis.

How to Make Nitrogen Gas

Nitrogen gas is made by separating nitrogen from the air. Air is about 78% nitrogen. There are several ways to make nitrogen. Some of the most common methods are air separation, pressure swing adsorption (PSA), and membrane separation. Each method has its own advantages and is used for different things. Some of the things that determine which method is used include how pure the nitrogen needs to be, how much nitrogen needs to be made, and what the nitrogen is going to be used for.

Methods of Making Nitrogen Gas

Air Separation

How it works: Air separation uses the fact that the different things in air have different boiling points to separate nitrogen from the air. First, the air is compressed. Then, it is cooled to very cold temperatures so that it turns into a liquid. The different things in air are separated by boiling them out one at a time, and nitrogen is collected. The air is cooled to about -200°C (-328°F). At this temperature, nitrogen turns into a liquid at -196°C (-320°F), but oxygen turns into a liquid at -183°C (-297°F).

Advantages: Makes very pure nitrogen (up to 99.999%). This is good for making lots of nitrogen in big factories. It can also make other things like oxygen and argon.

Disadvantages: Needs complicated equipment, costs a lot of money, uses a lot of energy. It takes a lot of stuff to make air really cold and keep it that way. You have to make a lot of nitrogen to make it worth the trouble.

Applications: Chemical plants, big food factories, and other places that need very pure nitrogen. It is also used to make steel and electronics.

Pressure Swing Adsorption (PSA)

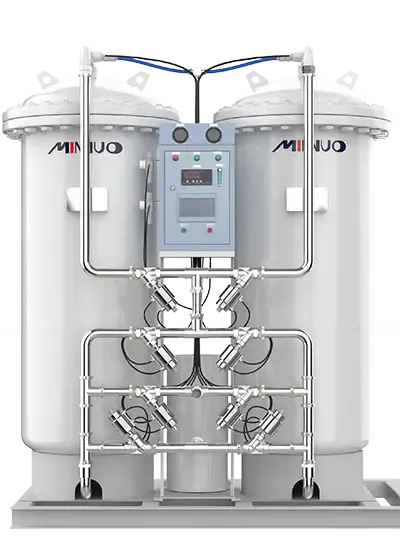

How it works: PSA uses special stuff to take nitrogen out of the air. The special stuff grabs the oxygen and other bad things in the air, but leaves the nitrogen behind. When the special stuff gets full, it lets go of the oxygen and other things and grabs some more. The special stuff is made of things like zeolites and activated carbon.

Advantages: Uses simple equipment, easy to run, doesn’t use a lot of energy. PSA machines can be small or big, depending on how much nitrogen you need.

Disadvantages: Makes nitrogen that isn’t as pure (between 95% and 99.9%). The purity depends on how much pressure you use and how good the special stuff is.

Applications: Medium-sized factories, places that need some nitrogen but not a lot, like food packaging, electronics, and metal stuff. People also use PSA machines in labs and to keep chemicals safe.

Membrane Separation

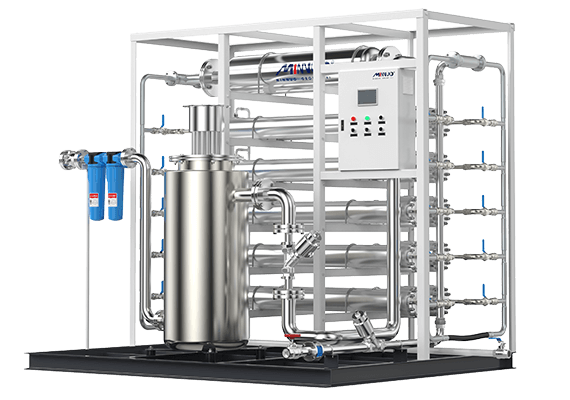

How it works: Membrane separation uses special stuff to let some things pass through and keeps other things behind. When air goes through the special stuff, the little things like oxygen go through more easily than the big things like nitrogen. The special stuff is made of things like polysulfone and polyimide.

Advantages: Uses small machines, easy to put in and take care of, starts up fast. Membrane machines don’t use a lot of energy and don’t take up much space.

Disadvantages: Makes nitrogen that isn’t as pure (between 90% and 99%). The machines can be affected by how much water is in the air and how hot it is.

Applications: Small factories, places that need nitrogen fast and don’t need a lot, like gas tanks, chemicals, and simple packages. People also use membrane machines on oil rigs to clean out pipes.

How to Choose the Right Way to Make Nitrogen

The right way to make nitrogen depends on a few things. You need to know how pure you need the nitrogen to be, how much you need, and what you are going to use it for.

Air Separation: If you need a lot of really pure nitrogen (up to 99.999%) and you make a lot of stuff, this is the way to go.

Pressure Swing Adsorption (PSA): If you need nitrogen that is pretty pure (between 95% and 99.9%) and you make some stuff, this is the way to go.

Membrane Separation: If you need nitrogen that is pretty pure (between 90% and 99%) and you don’t make a lot of stuff, this is the way to go.

Conclusion

Knowing how nitrogen gas is made and how it is used in different industries can help you choose the right way to make it. Each way has its advantages and is used for different things. Whether you make a lot of stuff or just a little, there is a way to make nitrogen that is right for you.

Minnuo is a professional nitrogen plant manufacturer that makes nitrogen gas. We have had many nitrogen projects around the world, and those interested can contact us to customize your nitrogen generator.

Frequently Asked Questions

You can get pure nitrogen gas through air separation, PSA technology, and on-site generation systems. Each method ensures the nitrogen is free from impurities, making it suitable for various applications. For high-purity requirements, you’ll typically use air separation units (ASUs). For medium to high purity, PSA systems are effective and more flexible.

Yes, you can make your own nitrogen on-site using nitrogen generators that use membrane or PSA technology. These systems are designed to be easy to use and can provide a continuous supply of nitrogen. On-site nitrogen generation eliminates the need to transport and store nitrogen cylinders, which reduces costs and logistical challenges.

Making nitrogen gas at home is difficult because you need specialized equipment. However, there are small-scale nitrogen generators available for specific applications that require a reliable nitrogen supply. These generators use PSA or membrane technology and are designed to be easy to use, which makes them a convenient solution for hobbyists or small-scale applications.

sales2:+86 17506119168

sales2:+86 17506119168