Are you concerned about the stability and cost of oxygen supply in industrial production? An industrial oxygen generator may be the ideal solution. However, before making a purchase, it is crucial to understand the various factors that influence the price. This will not only help you make an informed decision but may also save you significant costs.

The price of industrial oxygen generators can fluctuate significantly due to various factors, such as oxygen production capacity, oxygen purity, altitude, ambient temperature, the technology used, and the brand.Generally, small oxygen generators range from $5,000 to $30,000, medium-sized ones cost around $30,000 to $80,000, while large industrial oxygen generators can exceed $100,000. Understanding these factors will help you select the most suitable oxygen generator for your business needs.

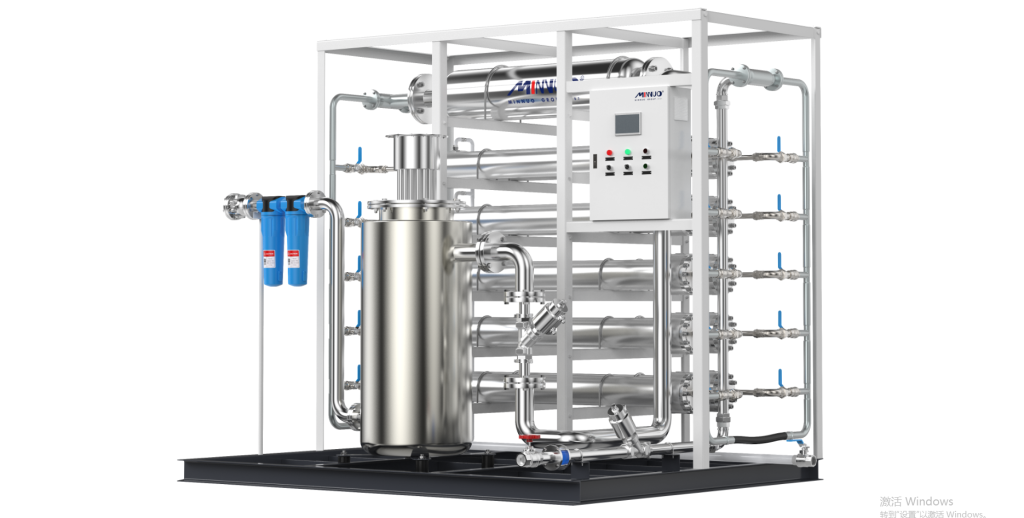

What is an Industrial Oxygen Generator?

An industrial oxygen generator is a device that extracts high-purity oxygen from the air. The principle is based on the physical characteristics of different gases under specific conditions. Technologies such as pressure swing adsorption (PSA), membrane separation, and cryogenic separation are used to separate oxygen from the air, providing a stable and reliable source of oxygen for industrial production. These generators are widely used in industries such as steel, chemicals, and healthcare.

Types of Industrial Oxygen Generators

Pressure Swing Adsorption (PSA) Oxygen Generators

Small and Medium-sized PSA Oxygen Generators

These are commonly used for small to medium-scale oxygen production where purity requirements are moderate (90%-99%). The principle involves separating oxygen through an adsorbent under pressure variations. Prices typically range from $1,500 to $40,000, depending on oxygen capacity, automation, and adsorbent performance. These generators are easy to operate, flexible in starting and stopping, and have low installation requirements, making them suitable for industries such as metal processing, food packaging, and general medical applications.

Large VPSA (Vacuum Pressure Swing Adsorption) Oxygen Generators

These are used for large-scale oxygen production and can meet the high oxygen demands of large industrial enterprises, such as in the chemical and steel industries. Prices typically exceed $100,000 due to their high oxygen production capacity, large scale, and complex equipment, with an increased need for stability and efficiency in large-scale operations.

Membrane Separation Oxygen Generators

These generators rely on polymer membranes for selective gas permeation and are suitable for low-purity oxygen (40%-50%) applications, with an emphasis on compactness and low energy consumption. Prices range from $5,000 to $25,000, depending on membrane performance, production scale, and system integration. They are ideal for industries like electronics manufacturing, aquaculture, and small chemical labs, offering quiet operation, space-saving design, low energy consumption, and easy maintenance.

Cryogenic Oxygen Generators

Using cryogenic technology, these generators cool the air to very low temperatures and separate oxygen based on boiling point differences (99.6% purity and above). Prices usually exceed $100,000 due to the complexity of the manufacturing process and high technical requirements. They are used in large-scale industries such as steel, petrochemical, and aerospace. Though the initial investment is high, they are critical for ensuring the continuity and quality of high-end industrial production.

Key Factors Affecting Costs

Oxygen Production Capacity

Oxygen production capacity is a key factor in determining price. The larger the capacity, the greater the compression and processing power required, which leads to higher costs. For example, equipment producing 50 cubic meters of oxygen per hour can cost 50%-100% more than a 10 cubic meter unit due to the increased complexity of core components, supporting equipment, and systems.

Oxygen Purity

The demand for high-purity oxygen drives up the price of oxygen generators, which is why many enterprises want to know how to choose industrial oxygen generator based on purity. For example, when the purity increases from 95% to 99%, the price may double to cover the high-end purification equipment, process development, and monitoring systems. Businesses must balance the increase in purity with the associated cost.

Altitude

At higher altitudes, the air is thinner, requiring larger capacity compressors. As a result, the cost of equipment increases.

Ambient Temperature

Ambient temperature can impact the equipment. For example, in environments as cold as -30°C, special treatments are necessary, such as adding antifreeze to compressors, incorporating air dryers, filters, heating tapes for drainage systems, and installing heaters in air buffer tanks.

Technology and Process

Advanced technology improves equipment performance and energy efficiency, resulting in higher initial prices but providing long-term cost savings and increased efficiency. Compared to traditional equipment, the price may be 10%-20% higher, and businesses should consider the total lifecycle cost and benefits.

Brand and Manufacturer

Well-known brands like Ingersoll Rand and Siemens often come with a 10%-20% price premium due to their investments in technology development, quality control, reputation, and after-sales service. These brands reduce the risk of production interruptions and are a trusted investment.

Custom Requirements and Additional Features

Meeting special requirements and incorporating additional features can increase costs by 10%-15%, depending on the complexity of customization. While these features enhance performance, they also add to the procurement and maintenance costs.

Accessories and Auxiliary Equipment

The price of industrial oxygen generators is significantly influenced by the need for additional equipment and accessories. These include:

Air Compressor

A key component of the oxygen generator, providing compressed air. The cost depends on the capacity, type (e.g., screw-type, piston-type), brand, and energy efficiency, typically ranging from $2,000 to $15,000. Large-capacity, energy-efficient brand compressors are more expensive, while smaller, basic models are cheaper.

Air Storage Tank

Used for storing compressed air, available in dry and wet versions. Dry tanks store dry air to prevent moisture and impurities from affecting the system, while wet tanks are used to store air with higher humidity in environments where humidity control is less critical. The price of storage tanks depends on capacity and material, typically ranging from a few hundred dollars to several thousand dollars.

Air Filter

Removes dust and impurities from the air to prevent damage to equipment. Prices depend on filtration accuracy, material, and size, usually ranging from a few hundred to several thousand dollars. High-precision, long-lasting filters tend to cost more.

Dryer

Reduces moisture in the air to prevent corrosion and maintain oxygen purity. Prices typically range from $1,000 to $8,000, depending on drying principles, processing capacity, and brand.

Oxygen Storage Tank

Used to store oxygen and ensure a stable supply. Prices are affected by capacity, material, and craftsmanship, typically ranging from $1,500 to over $10,000. Larger-capacity, stainless steel tanks tend to be more expensive.

Oxygen Booster

Used to increase the pressure of oxygen to the required level for different applications. When oxygen needs to be filled into oxygen cylinders to a pressure of 150 bar or 200 bar, or in equipment with a pressure greater than 6kg, an oxygen booster is required. The price of oxygen boosters varies depending on boosting capability, technology level, brand, and associated equipment, typically ranging from several thousand dollars to tens of thousands of dollars.

Maintenance and Operational Costs

While the initial purchase price is important, it is equally essential to consider long-term maintenance and operational costs. These include replacement of consumables, energy consumption, and equipment upkeep. Power consumption is related to equipment power and operating time, so maintenance and operational costs should be evaluated comprehensively.

Detailed Cost Breakdown

To help you better understand the expected costs, we have broken down the costs for small, medium, and large oxygen generators as follows:

Small Oxygen Generator

Price: $1,500 – $30,000

Suitable for small factories or scenarios with low oxygen demand, such as small machining operations, laboratories, etc. It provides oxygen with lower purity and smaller flow rates.

Medium Oxygen Generator

Price: $30,000 – $80,000

Meets the oxygen needs of medium-sized businesses, used in industries like chemicals, medium-sized metal processing, etc. It offers moderate oxygen purity and output.

Large Oxygen Generator

Price: $100,000 and above

Used in large industrial enterprises for high-load oxygen supply, commonly found in steel production, large-scale chemicals, and similar industries. It provides high purity and large output.

If the specifications of the oxygen generator are uncertain, businesses can consult with professional technicians for advice on selection and quotations to ensure that the appropriate equipment is chosen to meet production needs and control costs.

Cost-Benefit Analysis: Is It Worth the Investment?

On-Site Oxygen Generation vs. Bottled Oxygen Supply

Businesses need to weigh the pros and cons of on-site oxygen generation versus purchasing bottled oxygen. Here is a brief cost comparison between the two:

Bottled Oxygen Supply

If a business spends $15,000 annually on bottled oxygen, the total cost over ten years could reach $150,000 or higher. Additionally, there may be hidden costs such as unstable supply, purity fluctuations, and inconvenient transportation and storage, all of which can impact business operations.

On-Site Oxygen Generation

If a $40,000 industrial oxygen generator is invested, the initial investment could be recouped in about 2.5 to 3 years. Long-term operating costs are mainly related to maintenance and electricity consumption, offering a clear cost advantage over bottled oxygen. On-site generation ensures a stable oxygen supply, controlled purity, and the flexibility to adjust output according to demand.

Cost Breakdown of On-Site Oxygen Generation Systems

Unlike bottled oxygen supply, the cost structure of on-site oxygen generation systems is more complex and mainly covers the following aspects:

- Electricity Consumption: This primarily comes from the air compressor, cooling system, and oxygen generator. The larger the compressor power and the longer the operating time, the higher the electricity costs. For example, a 50m³/h oxygen generator with a 75kW compressor would have an electricity cost of approximately $7.5 per hour. If operated for 2,000 hours annually, the total electricity cost would be around $15,000.

- Labor Costs: Due to the high level of automation, labor costs are relatively low, typically requiring only periodic inspections and maintenance, with annual costs ranging from $1,000 to $2,000.

- Equipment Maintenance Costs: This includes the replacement and calibration of components such as filters, adsorbents, valves, and instruments. For example, the air filter needs to be replaced every 2,000 hours, costing around $100 to $500; the molecular sieve needs to be replaced every 5-8 years, costing around $5,000 to $8,000. The annual maintenance cost is estimated to be between $5,000 and $10,000, depending on the equipment brand, quality, and operating environment.

- Depreciation Costs: Equipment is typically depreciated over an 8-10 year period. For a $50,000 machine, the annual depreciation cost would be approximately $5,000 to $6,250, reflecting the loss in equipment value.

Conclusion

The price of industrial oxygen generators is influenced by a variety of factors. Before making a purchase, companies should comprehensively consider their production needs, budget, and long-term operational costs. By conducting a detailed cost-effectiveness analysis, they can choose the most suitable oxygen generator for their development, optimizing resource allocation and maximizing economic benefits.

Attachment:

How to Purchase Industrial Oxygen Generators?

At MINNUO, we offer a wide variety of industrial oxygen generators, covering various technical types and specifications. You can place an order directly, and we guarantee competitive prices. If you have any questions regarding product selection, feel free to contact our team of professional engineers. We will customize solutions for you and provide detailed pricing plans.

Frequently Asked Questions

How much oxygen can an industrial oxygen generator produce?

The oxygen production capacity of an oxygen generator depends on the model and technical parameters. Small units can produce several cubic meters of oxygen per hour, while large industrial oxygen generators can produce up to hundreds of cubic meters per hour. Enterprises need to clarify their oxygen requirements to select the appropriate model. Technicians can also recommend suitable equipment based on the application scenario.

What is the lifespan of an industrial oxygen generator?

The typical lifespan is 8 to 12 years, influenced by maintenance, operating environment, and usage frequency. Regular maintenance can extend the lifespan, and our professional after-sales service team can provide maintenance plans and technical support to ensure stable operation, reduce the risk of failure, and enhance production efficiency.

How reliable are industrial oxygen generators?

Modern industrial oxygen generators are made with advanced technology, offering high reliability under normal maintenance, and can meet the needs of continuous industrial production. Oxygen generators from well-known brands undergo rigorous testing, meeting stability and durability standards. They are suitable for various industrial fields, and enterprises can ensure reliable operation by choosing high-quality brands and proper maintenance.

sales2:+86 17506119168

sales2:+86 17506119168