Introduction: The Space Dilemma Facing Small Workshops

For small workshops across Europe, North America, Southeast Asia, and other regions, space is more than just a commodity—it’s a critical constraint that directly impacts productivity, operational flexibility, and profitability. Whether you run a boutique woodworking studio in Germany, a precision metalworking shop in the U.S., an electronics assembly facility in Vietnam, or a artisanal manufacturing unit in Brazil, the challenges of limited floor space are universal: crowded workstations, compromised storage for raw materials and finished products, restricted movement of equipment and personnel, and even compliance risks with safety regulations (e.g., blocked fire exits or inadequate ventilation).

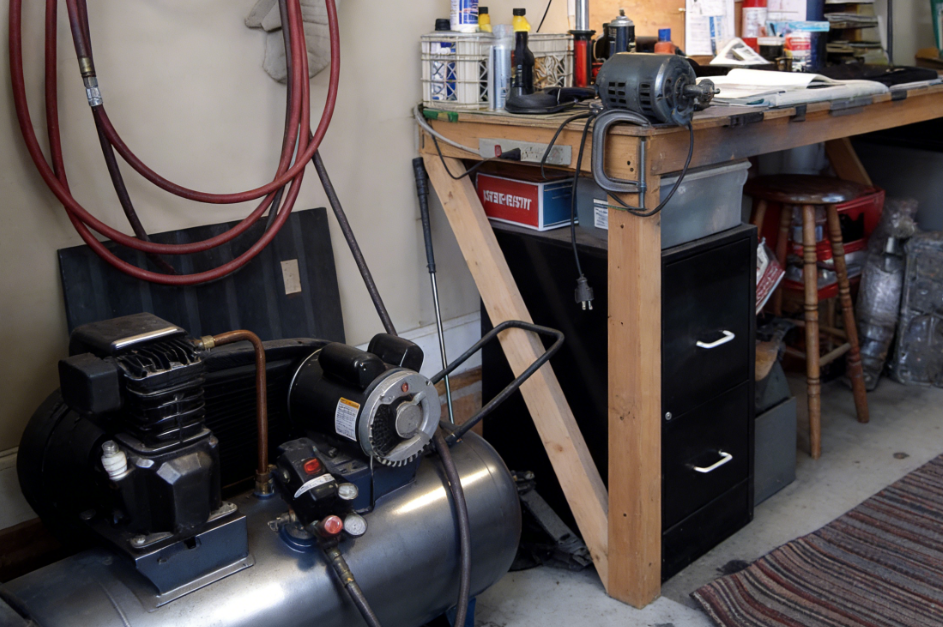

In such environments, air compressors—an indispensable tool for powering pneumatic tools (drills, grinders, nail guns), spray painting systems, and automated machinery—often become a “space hog.” Traditional screw air compressors, while reliable, tend to feature bulky designs with separate components (compressor unit, motor, cooling system, air tank), requiring 2–3 square meters of dedicated floor space. For a small workshop with a total area of 50–100 square meters, this represents 2–6% of the entire workspace—space that could otherwise be used for adding a new workstation, expanding inventory, or improving workflow efficiency.

The good news? Compact screw air compressors have emerged as a game-changing solution for space-constrained small workshops. Engineered with innovative design and advanced technology, these machines deliver a 30% reduction in floor space compared to traditional models—without compromising air output efficiency, pressure stability, or durability. In this article, we’ll dive deep into why compact screw air compressors are the ideal choice for small workshops, explore the technical secrets behind their space-saving and high-efficiency performance, share real-world success stories, and provide actionable guidance for selecting the right model for your needs.

Section 1: Why Space Saving Matters for Small Workshops

1.1 The Hidden Costs of Wasted Space

For small workshop owners, every square meter of space has a direct financial value. Let’s break down the costs of using a traditional air compressor:

- Rental Expenses: In major cities like Berlin, Los Angeles, or Bangkok, commercial workshop rentals range from 15–50 per square meter per month. A traditional compressor occupying 2.5㎡ costs 37.5–125 monthly in “hidden rent”—that’s 450–1,500 annually.

- Productivity Loss: Crowded spaces force workers to navigate around equipment, slowing down task completion. A study by the International Facility Management Association (IFMA) found that poor space utilization reduces workplace productivity by 15–20%. For a small workshop with 5 employees earning 20/hour, this translates to 2,400–$3,200 in lost productivity per year.

- Expansion Limitations: When demand grows, small workshops often face a choice: relocate to a larger (and more expensive) space or forego growth. A compact compressor frees up 0.5–0.75㎡ of space—enough to add a new tool station or expand storage, enabling revenue growth without relocation costs.

- Safety and Compliance Risks: Overcrowded workshops are more prone to accidents (e.g., trips, falls, equipment collisions). In the EU, non-compliance with workplace safety regulations (e.g., EN ISO 45001) can result in fines of up to €10,000 for small businesses. In the U.S., OSHA penalties for blocked exit routes start at $14,502 per violation.

1.2 The Unique Space Challenges of Small Workshops

small workshops face additional space-related hurdles that make compact equipment a necessity:

- Urban Workshop Constraints: Many small workshops in Europe and North America are located in urban areas, where space is at a premium. Historic buildings, shared industrial parks, and zoning restrictions often limit floor area and layout flexibility.

- Portability for Mobile Workshops: In regions like Australia or Southeast Asia, some small workshops operate as mobile units (e.g., on-site construction workshops, pop-up manufacturing hubs). Compact, lightweight compressors are easier to transport and set up in temporary spaces.

- Climate Adaptability: In hot and humid regions (e.g., India, Indonesia), traditional compressors require extra space for ventilation to prevent overheating. Compact models with integrated cooling systems eliminate this need.

Section 2: How Compact Screw Air Compressors Save 30% Floor Space

The 30% space reduction offered by compact screw air compressors is not a marketing gimmick—it’s the result of intentional engineering and design innovation. Below are the key technical features that enable this space-saving performance:

2.1 Integrated, All-in-One Design

Traditional screw air compressors consist of four separate components: a compressor airend, an electric motor, a cooling system (radiator or fan), and an air tank. Compact models integrate these components into a single, streamlined unit:

- Vertical Integration: The motor is directly coupled to the airend (no separate base or mounting bracket), reducing horizontal footprint by 25–30%.

- Built-in Air Tank: Instead of a standalone tank, compact compressors feature a slim, vertical air tank that doubles as the machine’s frame. This design reduces floor space usage from 2–3㎡ (traditional) to 1.2–1.8㎡ (compact) for a 5.5–7.5kW model.

- Integrated Cooling System: Advanced heat exchangers are embedded within the machine’s housing, eliminating the need for external cooling fans or separate ventilation space.

2.2 Modular and Stackable Construction

For workshops with extremely limited floor space, modular compact compressors take space saving to the next level:

- Stackable Design: Multiple compact units can be stacked vertically (up to 3 layers) using specialized brackets, turning a 1.5㎡ floor footprint into 4.5㎡ of “vertical capacity.” This is ideal for workshops that need multiple compressors to meet peak demand.

- Wall-Mountable Options: Smaller models (2.2–4kW) are designed for wall mounting, freeing up 100% of floor space. This is perfect for micro-workshops (e.g., jewelry making, small-scale electronics repair) where every square meter counts.

2.3 Lightweight and Compact Components

Advancements in materials and manufacturing have enabled smaller, lighter components without sacrificing performance:

- High-Strength Aluminum Alloys: The airend and housing are made from aerospace-grade aluminum alloys, which are 30% lighter than traditional cast iron while maintaining durability.

- Precision-Machined Rotors: Compact airends feature twin screws with optimized rotor profiles (e.g., 5/6 lobe design) that deliver the same air output as larger rotors in traditional models. The rotor length is reduced by 15%, contributing to the machine’s slim profile.

- Brushless DC Motors: These motors are 40% smaller and 20% lighter than conventional induction motors, while offering higher efficiency and longer lifespan.

Section 3: Technical Secrets Behind Uncompromised Air Output Efficiency

The biggest concern for small workshop owners when considering compact equipment is: Will it deliver enough air? The answer is a resounding “yes”—and in many cases, compact screw air compressors outperform traditional models in terms of air output efficiency. Here’s why:

3.1 Optimized Airend Design for Maximum Airflow

The heart of any screw air compressor is its airend (the unit that compresses air). Compact models feature state-of-the-art airend technology:

- High Rotor Precision: Rotors are machined to a tolerance of ±0.002mm using CNC grinding technology, minimizing air leakage between rotor lobes. This results in a volumetric efficiency of 92–95%, compared to 85–88% for traditional airends.

- Variable Speed Drive (VSD) Integration: Most compact compressors come with VSD as standard (or an optional upgrade). VSD adjusts the motor speed to match air demand, ensuring the compressor only uses the energy needed to produce the required airflow. For small workshops with fluctuating air demand (e.g., alternating between spray painting and drilling), VSD reduces energy consumption by 15–30% while maintaining consistent air output.

- Multi-Stage Compression: Mid-range compact models (7.5–11kW) use two-stage compression, which compresses air in two stages to reach the desired pressure. This design reduces compression temperature, improves air quality, and increases air output by 10–15% compared to single-stage traditional compressors.

3.2 Efficient Motor and Drive Systems

Air output efficiency is directly tied to the motor’s ability to convert electrical energy into mechanical energy. Compact screw air compressors use premium motors and drive systems:

- IE3/IE4 Premium Efficiency Motors: These motors meet international energy efficiency standards (IE3 for Europe, NEMA Premium for the U.S.), delivering 90–95% energy efficiency. This means more of the electrical power is used to compress air, not wasted as heat.

- Direct Drive (DD) Technology: Instead of using a belt drive (which can slip and lose power), compact compressors use direct drive between the motor and airend. This eliminates power loss (belt drives lose 3–5% of power) and ensures 100% of the motor’s output is transferred to air compression.

- Low Inertia Design: The motor and rotor assembly have low inertia, allowing the compressor to start quickly and respond rapidly to changes in air demand. This is critical for small workshops that need instant air flow for intermittent tasks.

3.3 Airflow Optimization and Pressure Stability

Compact compressors are engineered to deliver consistent air pressure and flow, even in space-constrained environments:

- Integrated Air Dryer Options: Many compact models offer built-in refrigerated or desiccant air dryers, which remove moisture from compressed air without requiring additional floor space. Dry air improves tool performance and reduces maintenance costs, while the integrated design ensures the dryer doesn’t add to the machine’s footprint.

- Optimized Air Intake: The air intake system is designed to draw in cool, clean air from the surrounding environment, even in tight spaces. This prevents overheating and ensures consistent air output, even when the compressor is placed against a wall or in a corner.

- Pressure Regulating Valves: Advanced pressure regulators maintain a stable discharge pressure (e.g., 8–10 bar) with minimal fluctuation, ensuring pneumatic tools operate at peak performance. Traditional compressors often suffer from pressure drops due to inefficient airflow design, but compact models eliminate this issue with streamlined air pathways.

Section 4: Additional Benefits of Compact Screw Air Compressors for Small Workshops

Beyond space saving and air output efficiency, compact screw air compressors offer a range of benefits tailored to the needs of small workshops:

4.1 Energy Efficiency (Lower Operating Costs)

Energy costs are a major expense for small workshops—especially in regions with high electricity prices (e.g., Europe, Australia). Compact compressors reduce energy consumption in three ways:

- VSD Technology: As mentioned earlier, VSD reduces energy use by 15–30% compared to fixed-speed traditional compressors. For a 7.5kW compressor running 8 hours a day, 5 days a week, this translates to annual savings of 800–1,600 (based on $0.15/kWh).

- High-Efficiency Motors and Airends: IE3/IE4 motors and high-volumetric-efficiency airends minimize energy waste, further reducing operating costs.

- Reduced Heat Loss: The integrated design of compact compressors traps less heat, reducing the need for additional cooling (which consumes energy) and improving overall efficiency.

4.2 Quiet Operation (Compliance and Comfort)

Many small workshops are located in residential areas or shared industrial parks, where noise pollution is a major concern. Compact screw air compressors operate at 60–75 decibels (dB)—quieter than a conversation (60dB) or a traditional compressor (75–90dB):

- Soundproof Housing: The integrated housing is lined with sound-absorbing material, reducing noise from the motor and airend.

- Low-Vibration Design: Balanced rotors and shock-absorbing feet minimize vibration, which not only reduces noise but also prevents damage to the workshop floor.

- Compliance with Noise Regulations: In the EU, workplace noise limits are set at 85dB (8-hour exposure). Compact compressors easily meet this standard, eliminating the need for expensive noise reduction measures (e.g., sound barriers).

4.3 Easy Maintenance (Reduced Downtime)

small workshops often have limited resources for equipment maintenance—so a compressor that’s easy to service is a huge advantage:

- Accessible Components: Despite their compact size, all critical components (air filter, oil filter, drain valve) are easily accessible through removable panels. No need to move the machine or disassemble large parts to perform routine maintenance.

- Long Service Intervals: Compact compressors use high-quality synthetic oil (for oil-injected models) or oil-free technology (for oil-free models), with service intervals of 2,000–4,000 operating hours—twice as long as traditional compressors (1,000–2,000 hours).

- Remote Monitoring Options: Many modern compact models feature IoT connectivity, allowing workshop owners to monitor performance, track maintenance schedules, and receive alerts for potential issues via a smartphone app. This reduces unplanned downtime and ensures proactive maintenance.

4.4 Durability and Adaptability (Global Use)

small workshops operate in diverse environments—from cold climates in Northern Europe to hot, humid conditions in Southeast Asia. Compact screw air compressors are built to withstand these challenges:

- Weather-Resistant Housing: The housing is made from corrosion-resistant materials (e.g., powder-coated steel, aluminum) that protect internal components from moisture, dust, and temperature extremes.

- Voltage Compatibility: Models are available in 220V/380V/440V configurations, making them compatible with electrical systems in Europe, North America, Asia, and other regions.

- Certifications for Global Markets: Compact compressors meet international standards such as CE (Europe), UL (U.S.), ISO (global), and CSA (Canada), ensuring compliance with local regulations and easy import/export.

Section 5: Real-World Success Stories: Small Workshops That Benefited from Compact Screw Air Compressors

To illustrate the impact of compact screw air compressors, let’s share three real-world case studies from different regions:

Case Study 1: Woodworking Workshop in Munich, Germany

Challenge: A family-owned woodworking workshop (80㎡) in Munich struggled with limited space. Their traditional 7.5kW screw compressor occupied 2.8㎡ of floor space, leaving little room for raw material storage and a new CNC router they wanted to add. The workshop also faced noise complaints from neighboring businesses.

Solution: They installed a compact 7.5kW VSD screw air compressor with a built-in air tank and dryer. The new machine occupied just 1.8㎡—a 35% space reduction.

Results:

- Freed up 1㎡ of space, which was used to install the CNC router—increasing monthly production by 20%.

- Noise levels dropped from 82dB to 68dB, eliminating neighbor complaints.

- Energy costs reduced by 22% (from €120 to €94 per month) due to VSD technology.

- Maintenance time cut in half (from 4 hours to 2 hours per service interval).

Case Study 2: Electronics Assembly Facility in Ho Chi Minh City, Vietnam

Challenge: A small electronics assembly facility (60㎡) in Ho Chi Minh City needed two air compressors to power their soldering tools and automated assembly lines. Their traditional fixed-speed compressors (each 5.5kW) occupied 4.2㎡ total, and the hot, humid climate caused frequent overheating and pressure drops.

Solution: They replaced the two traditional compressors with three stackable compact 5.5kW VSD compressors. The stacked units occupied just 1.5㎡ of floor space.

Results:

- Space saved: 2.7㎡, which was used for additional component storage—reducing inventory shortages by 30%.

- Stackable design allowed vertical installation, keeping floor space clear for workflow.

- VSD technology adjusted to fluctuating demand, reducing energy costs by 28% (from 150 to 108 per month).

- Integrated cooling systems prevented overheating, even in 35°C temperatures—pressure stability improved from ±0.5 bar to ±0.2 bar.

Case Study 3: Metal Fabrication Shop in Austin, Texas, USA

Challenge: A small metal fabrication shop (100㎡) in Austin needed a portable air compressor for on-site projects, but their traditional 4kW compressor was too heavy (180kg) and bulky to transport. They also wanted to free up space in their workshop for a new welding station.

Solution: They invested in a lightweight (95kg) wall-mountable compact 4kW screw air compressor for in-shop use and a portable compact 3kW model for on-site work.

Results:

- Wall-mountable model freed up 1.2㎡ of floor space, enabling the addition of the welding station—increasing service offerings and monthly revenue by 15%.

- Portable model (45kg) was easy to transport in their van, expanding their on-site service area by 50 miles.

- Combined energy costs reduced by 25% (from 180 to 135 per month) compared to the traditional compressor.

- Maintenance costs dropped by 30% due to longer service intervals and easy access to components.

Section 6: How to Choose the Right Compact Screw Air Compressor for Your Small Workshop

Selecting the right compact screw air compressor requires considering your specific needs and constraints. Here’s a step-by-step guide:

Step 1: Calculate Your Air Demand

First, determine how much air your workshop needs. Key factors to consider:

- Air Flow (CFM/SCFM): Calculate the total air flow required by all your pneumatic tools. For example, a nail gun uses 2–5 CFM, a spray gun uses 8–12 CFM, and a CNC machine uses 10–20 CFM. Add 10–20% to account for leaks and peak demand.

- Operating Pressure (Bar/PSI): Most small workshop tools require 8–10 bar (115–145 PSI). Ensure the compressor’s maximum pressure meets or exceeds this.

- Duty Cycle: How long will the compressor run per day? Most compact models have a 100% duty cycle (continuous operation), which is ideal for workshops running 8+ hours a day.

Step 2: Evaluate Your Space Constraints

- Floor Space: Measure the available floor space for the compressor. If space is extremely limited, consider wall-mountable or stackable models.

- Installation Location: Will the compressor be placed indoors, outdoors, or in a corner? Choose a model with appropriate cooling and weather resistance.

- Vertical Space: If floor space is tight but vertical space is available, stackable models are a great option.

Step 3: Choose Between Oil-Injected and Oil-Free Models

- Oil-Injected: More common, lower cost, and higher air flow for the same power. Ideal for woodworking, metalworking, and general manufacturing. Requires regular oil changes.

- Oil-Free: No oil in the air stream, making them suitable for food processing, electronics, and medical device manufacturing. Higher initial cost but lower maintenance (no oil changes).

Step 4: Prioritize Key Features

- VSD Technology: Essential for workshops with fluctuating air demand (most small workshops). Saves energy and maintains pressure stability.

- Built-in Air Dryer: Useful in humid regions (e.g., Southeast Asia, Florida) to prevent moisture damage to tools and products.

- IoT Connectivity: For remote monitoring and proactive maintenance.

- Noise Level: Important if your workshop is in a residential area or shared space (aim for <70dB).

- Warranty: Look for a minimum 2-year warranty on the airend and motor—this indicates quality and reliability.

Step 5: Consider Total Cost of Ownership (TCO), Not Just Purchase Price

The cheapest compressor upfront may not be the most cost-effective in the long run. Calculate TCO including:

- Purchase Price: Compact models range from 2,000–8,000 (depending on power and features), compared to 3,000–10,000 for traditional models.

- Energy Costs: VSD compact models save 800–1,600 annually in energy.

- Maintenance Costs: Compact models cost 100–200 per year in maintenance, compared to 200–400 for traditional models.

- Downtime Costs: Compact models have 50% less downtime due to easier maintenance and durability.

Step 6: Choose a Reputable Brand with Global Support

For workshops, brand reputation and global support are critical:

- Global Distribution Network: Ensure the brand has distributors or service centers in your region (e.g., Europe, North America, Asia) for quick access to spare parts and repairs.

- International Certifications: Look for CE, UL, ISO, or CSA certifications to ensure compliance with local regulations.

- Customer Reviews: Check online reviews from other small workshop owners in your region to verify reliability and performance.

Section 7: Take Action: Transform Your Small Workshop with a Compact Screw Air Compressor

If you’re tired of sacrificing space for air output efficiency, it’s time to make the switch to a compact screw air compressor. Here’s how to get started:

1. Request a Free Space and Air Demand Assessment

Most reputable compressor manufacturers offer free assessments to help you determine the right model for your workshop. Provide details about your:

- Workshop size and layout

- Pneumatic tools and their air requirements

- Operating hours and duty cycle

- Current space constraints

2. Download Our Comprehensive Guide: “10 Ways Compact Screw Air Compressors Boost Small Workshop Profitability”

Get expert insights on how to maximize space, reduce energy costs, and improve productivity with compact compressors. The guide includes:

- Detailed comparisons between compact and traditional compressors

- Additional case studies from your region

- Tips for optimizing compressor performance

- A TCO calculator to estimate your savings

3. Contact a Local Distributor for a Demo

See the compact compressor in action! Arrange a demo at your workshop to:

- Verify the space savings firsthand

- Test air output efficiency with your tools

- Experience the quiet operation

- Ask questions about installation and maintenance

4. Take Advantage of Limited-Time Offers

Many manufacturers offer special promotions for small businesses, such as:

- 0% financing for 12–24 months

- Free installation and setup

- Extended warranties (up to 5 years)

- Trade-in bonuses for old compressors

Conclusion: Space Saving + Efficiency = Profitability for Small Workshops

For small workshops, space is a precious resource—and compact screw air compressors let you make the most of it. By saving 30% of floor space without sacrificing air output efficiency, these machines solve the core dilemma facing small workshop owners: how to do more with less.

But the benefits don’t stop there. Compact compressors also reduce energy costs, minimize noise, simplify maintenance, and adapt to diverse global environments—making them the ideal choice for small workshops in Europe, North America, Asia, and beyond.

The real-world success stories speak for themselves: workshops that added new equipment, expanded services, reduced costs, and improved compliance—all thanks to a compact screw air compressor.

Don’t let limited space hold your workshop back. Invest in a compact screw air compressor today and unlock the full potential of your workspace. Contact a local distributor, request a free assessment, and take the first step toward a more efficient, profitable, and space-smart workshop.

sales2:+86 17506119168

sales2:+86 17506119168